Air conditioner indoor unit cleanliness degree detection method and air conditioner

A cleanliness and air-conditioning internal unit technology, which is applied to the detection method of the cleanliness of the air-conditioning internal unit and the field of air-conditioning, which can solve problems such as inaccuracy, cleaning of dirty blockages inside the air-conditioning unit, and weakening of the heat dissipation effect of air-conditioning components, so as to achieve accurate detection results , Reduce installation costs, good cooling or heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

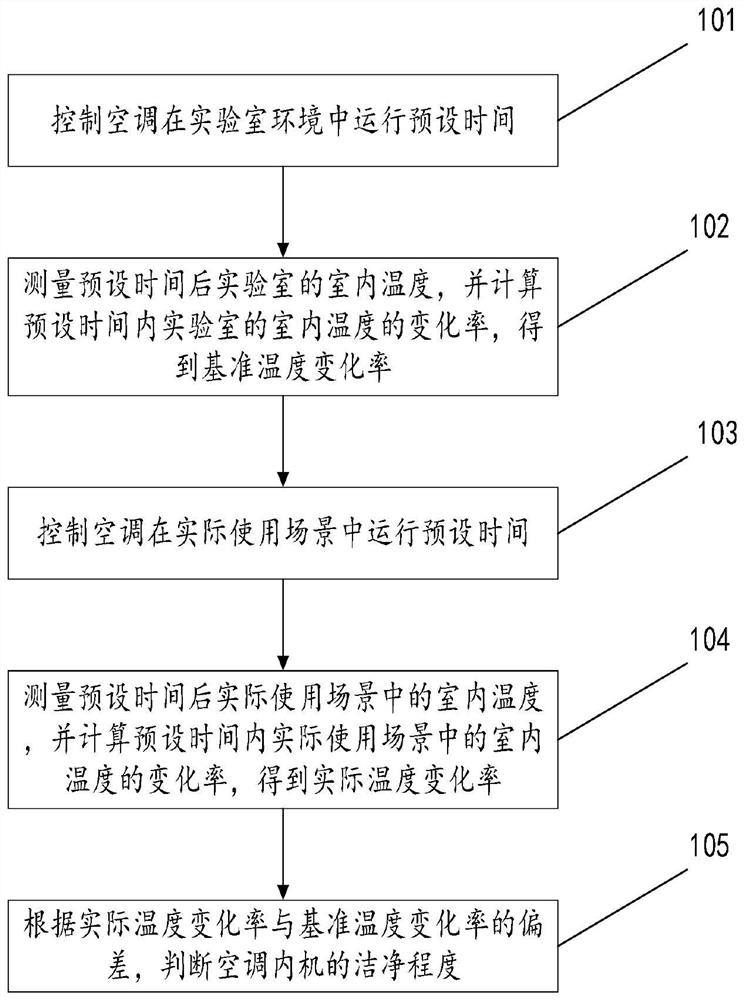

[0064] figure 1 It is a schematic flowchart of Embodiment 1 of the method for detecting the cleanliness degree of an air conditioner indoor unit shown in the embodiment of the present application.

[0065] see figure 1 , Embodiment 1 of the method for detecting the cleanliness of the air-conditioning internal unit in the embodiment of the present application includes:

[0066] 101. Control the air conditioner to run for a preset time in the laboratory environment;

[0067] The laboratory is a dust-free laboratory to avoid the interference of measurement and calculation data by dust and other impurities.

[0068] 102. Measure the indoor temperature of the laboratory after the preset time, and calculate the rate of change of the indoor temperature of the laboratory within the preset time to obtain the reference temperature rate of change;

[0069] 103. Control the air conditioner to run for a preset time in actual usage scenarios;

[0070] The preset times to control the ope...

Embodiment 2

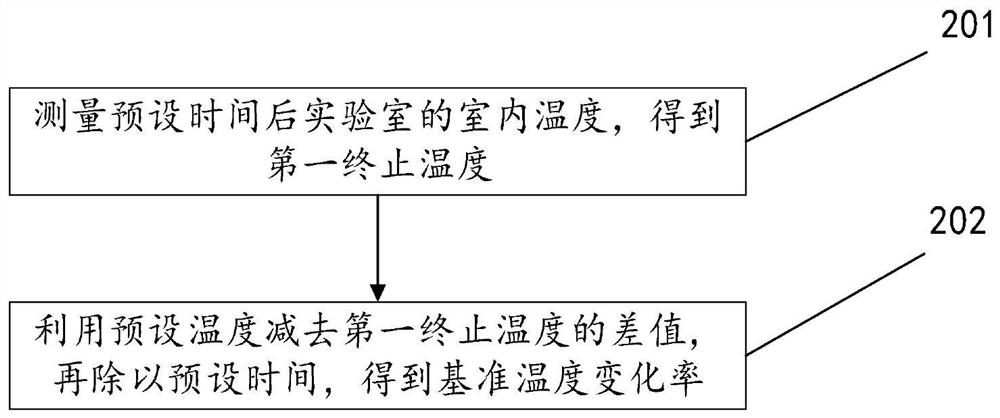

[0077] In practical applications, on the basis of the first embodiment, this embodiment specifically introduces how to calculate the reference temperature change rate.

[0078] figure 2 It is a schematic flowchart of Embodiment 2 of the method for detecting the cleanliness degree of an air conditioner indoor unit shown in the embodiment of the present application.

[0079] see figure 2 , Embodiment 2 of the method for detecting the cleanliness of the air-conditioning internal unit in the embodiment of the present application includes:

[0080] 201. Measure the indoor temperature of the laboratory after the preset time to obtain the first termination temperature;

[0081] 202. Use the difference of the preset temperature minus the first end temperature, and divide it by the preset time to obtain the base temperature change rate.

[0082] The laboratory environment also includes: the indoor temperature of the laboratory before the preset time is the preset temperature, the ...

Embodiment 3

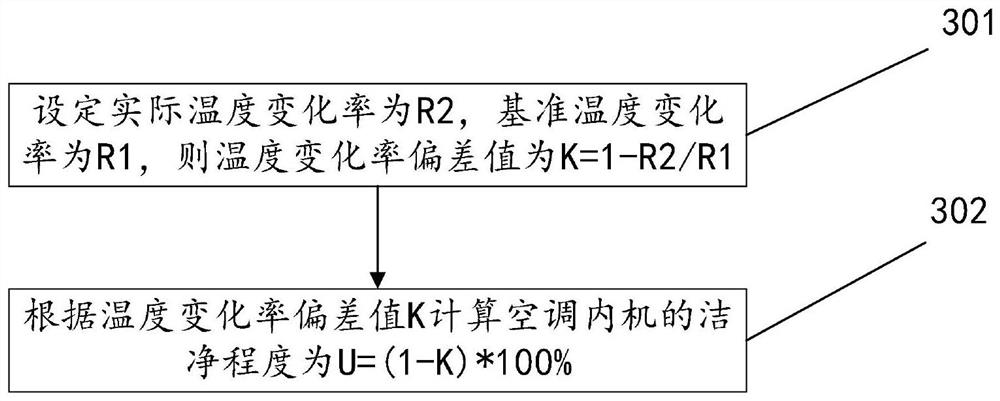

[0088] In practical applications, on the basis of the above embodiments, this embodiment introduces in detail how to judge the cleanliness of the air conditioner internal unit according to the deviation between the actual temperature change rate and the reference temperature change rate.

[0089] image 3 It is a schematic flow chart of Embodiment 3 of the method for detecting the cleanliness degree of an air conditioner indoor unit shown in the embodiment of the present application.

[0090] see image 3 , the third embodiment of the method for detecting the cleanliness of the air-conditioning internal unit in the embodiment of the present application includes:

[0091] 301. Set the actual temperature change rate R2 and the reference temperature change rate R1, then the temperature change rate deviation is

[0092] 302. Calculate the cleanliness degree of the air conditioner inner unit according to the deviation value K of the temperature change rate as U=(1-K)*100%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com