Diffusion end cover and motor

A technology of end caps and motor stators, used in electromechanical devices, electrical components, electric components, etc., can solve the problems of increased total flow, waste of total flow, excessive flow, etc., to reduce flow pressure loss, reduce medium flow speed, improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

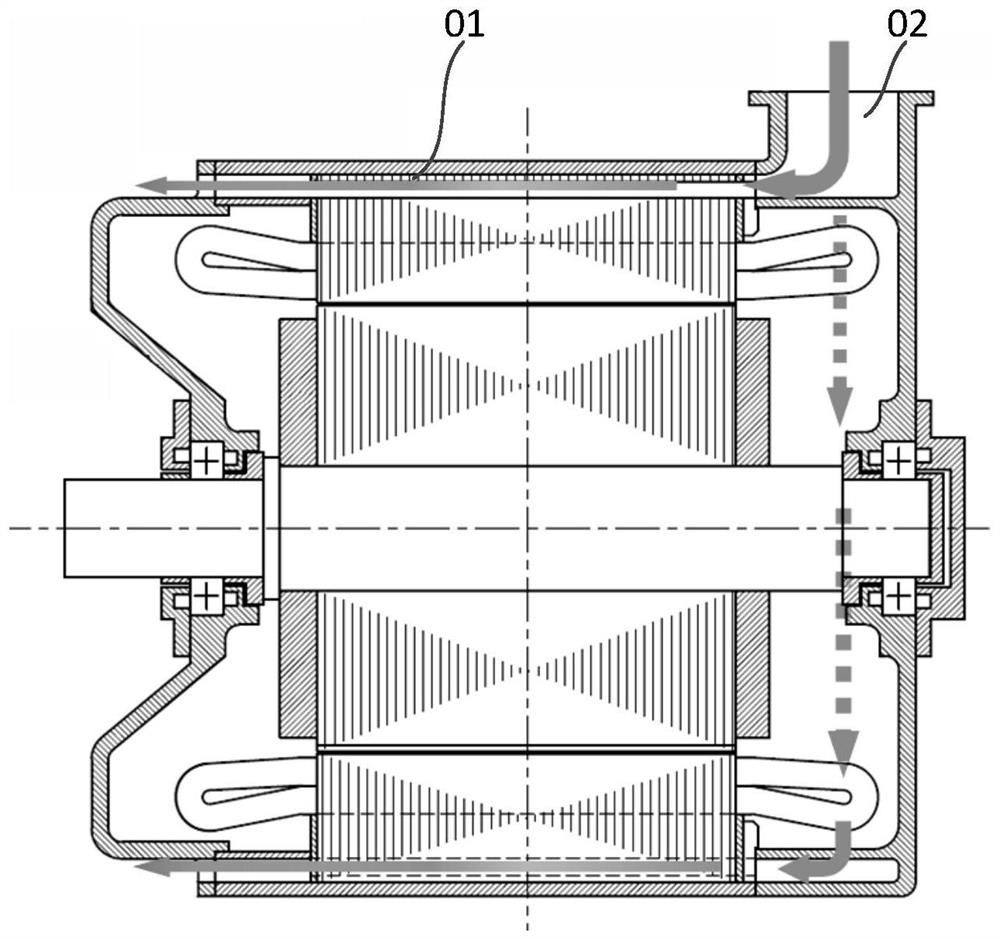

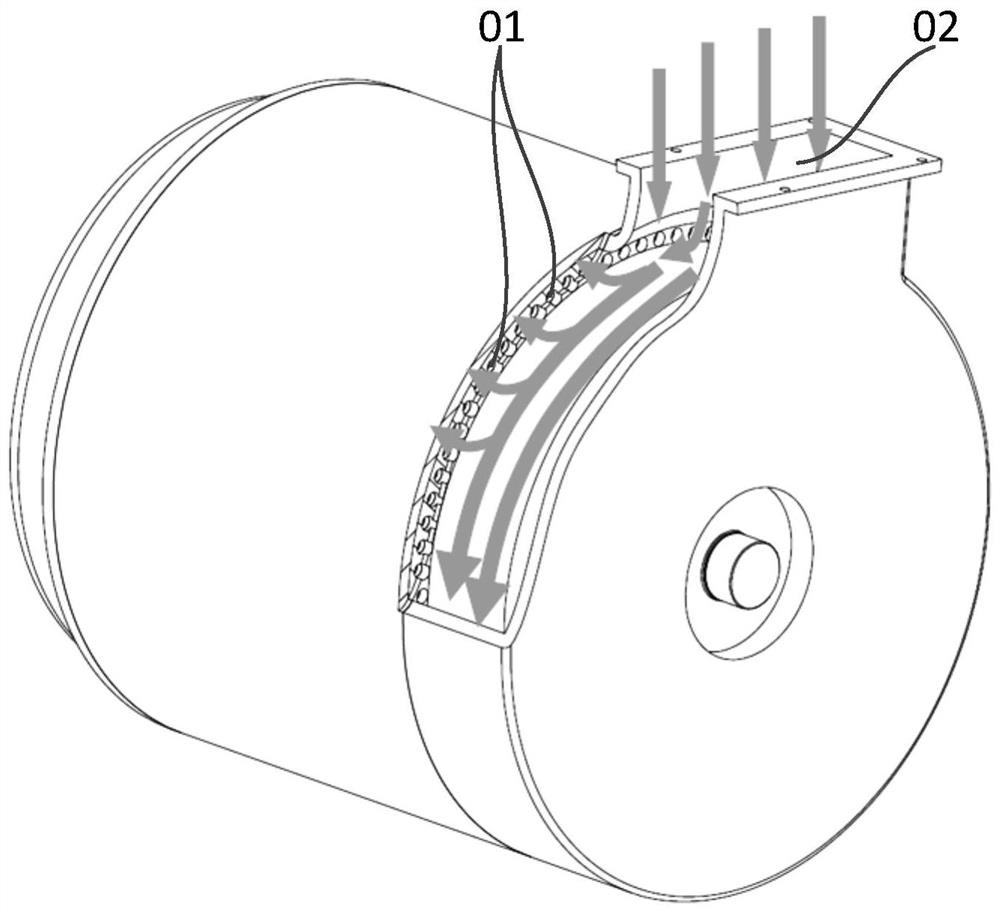

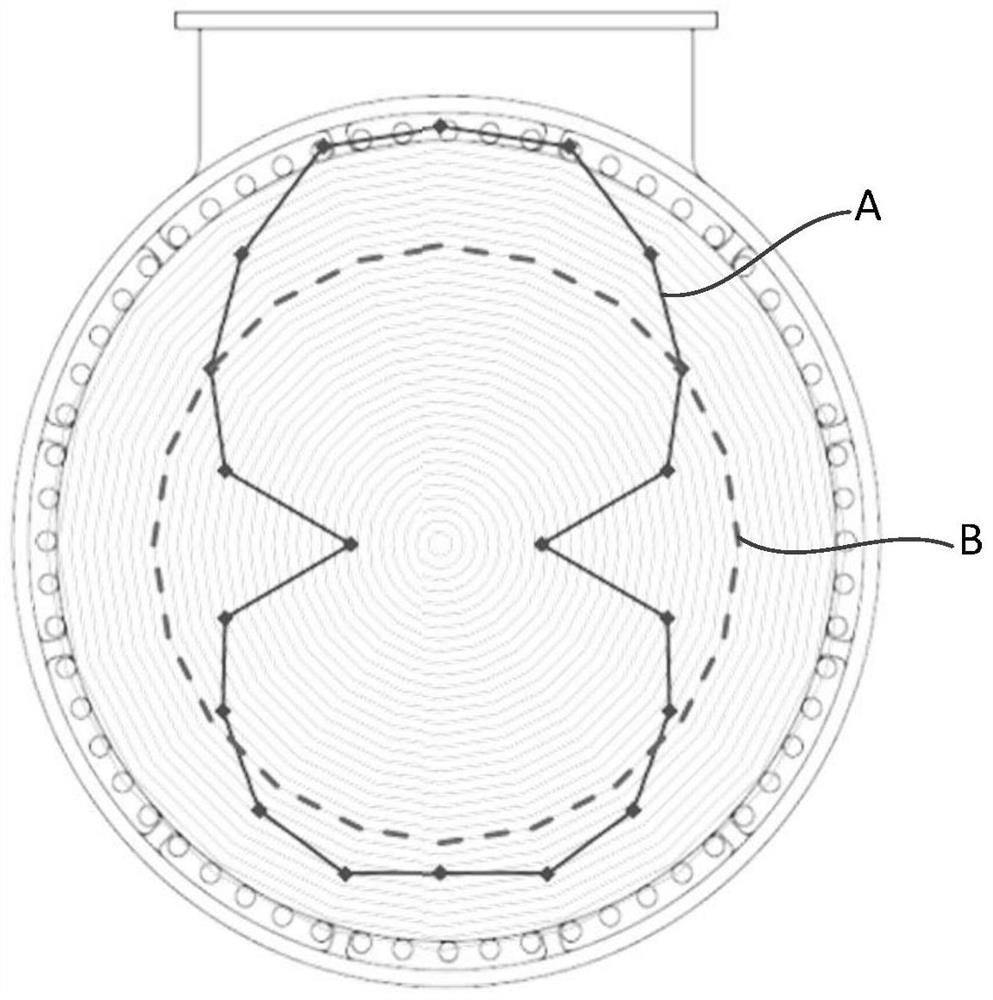

[0032] The core of the present invention is to provide a diffuser end cover. The disc-shaped airflow channel increases the internal airflow space, effectively reduces the flow velocity of the medium in the circumferential direction, distributes the airflow evenly, and makes the cooling effect in all places in the circumferential direction more uniform.

[0033] In order for those skilled in the art to better understand the technical solution of the present invention, the diffuser end cover and the motor of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0034] The diffuser end cover involved in the present invention is used for fixed docking with the motor stator shell, the diffuser end cover is fixed on one end of the motor stator shell, and the other end of the motor stator shell is fixed by the other end cover to form the entire motor shell structure.

[0035] Such as Figure 2A Sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com