Reciprocating type breeding processor for agricultural planting

A reciprocating and processor technology, applied in germination equipment and other directions, can solve the problems that the sieve tray cannot perform vibration operation, unfavorable safety operation, uneven seed turnover, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

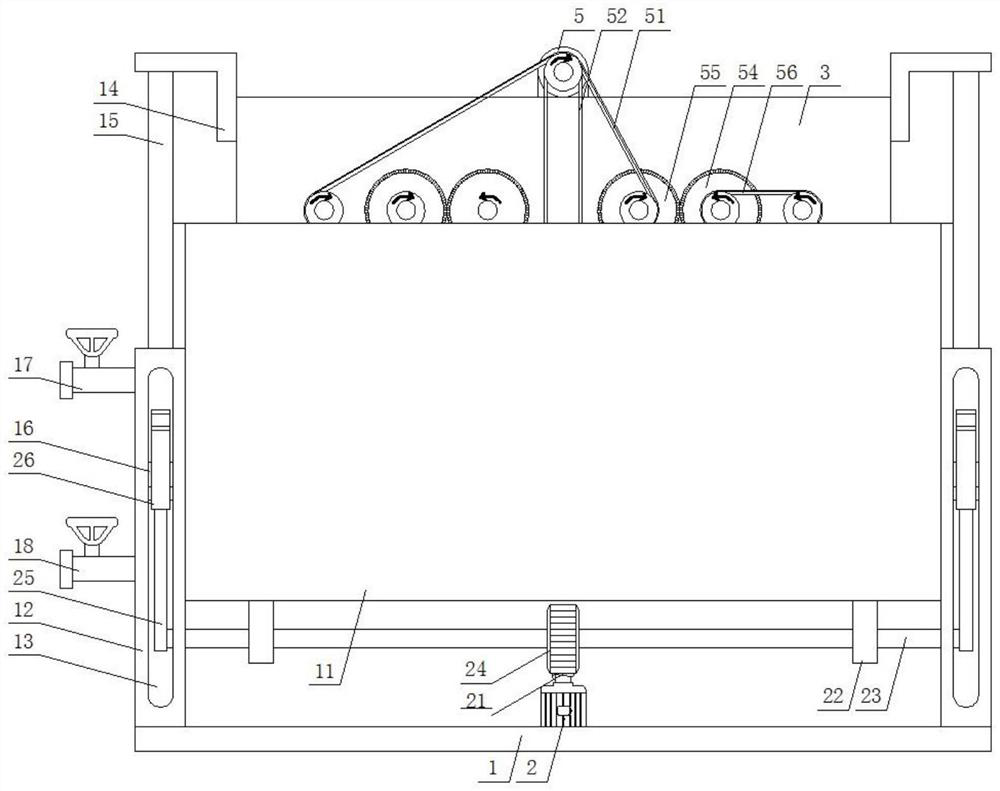

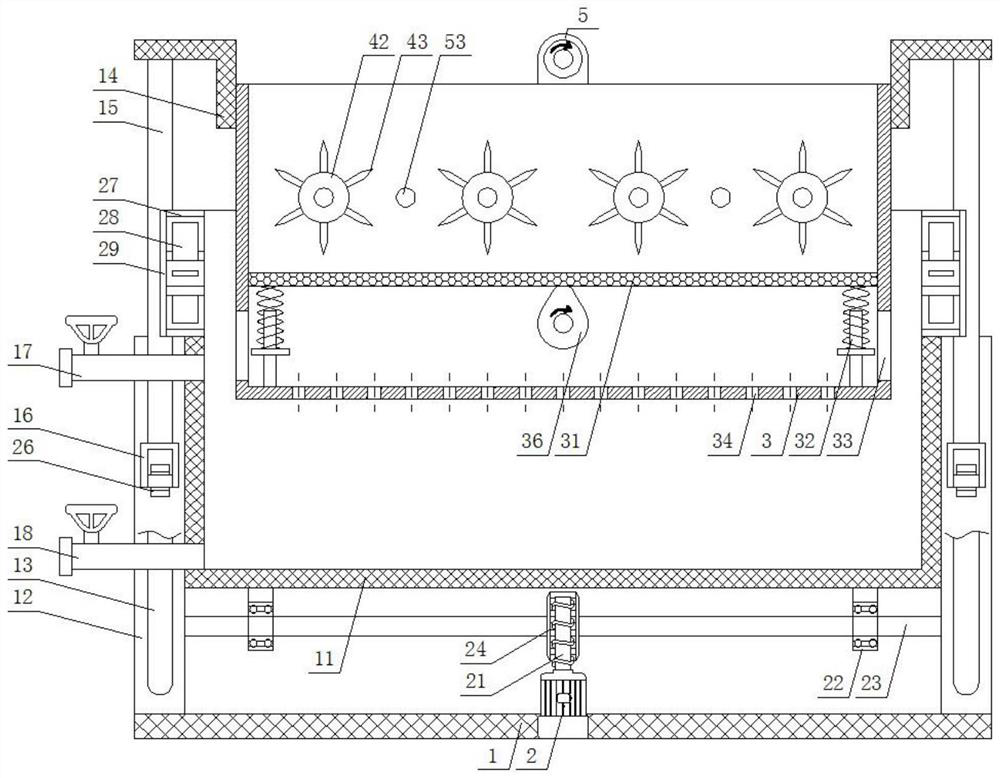

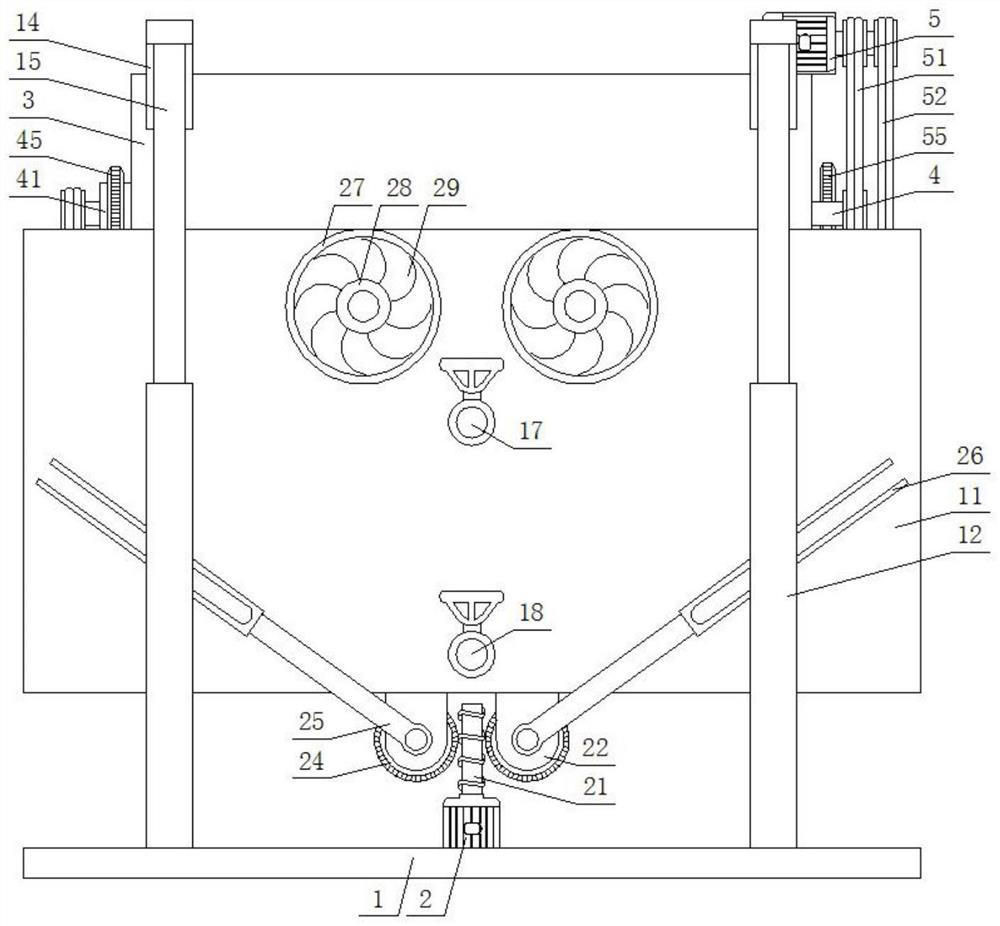

[0034] Embodiment 1: This embodiment provides a reciprocating breeding processor for agricultural planting, see Figure 1-8 , specifically, including a bottom plate 1, the bottom plate 1 is a rectangular plate placed horizontally and horizontally, a bottom box 11 placed in parallel and with an open top surface is arranged above the top surface of the bottom plate 1, and four corners of the top surface of the bottom plate 1 are provided with There is a vertically fixed rectangular sleeve 12, and the side corners of the bottom box 11 are fixed to the corresponding rectangular sleeve 12. The bottom box 11 is provided with an inner box 3 placed in parallel and with an open top surface. The mechanism is connected with the bottom plate 1; the middle and lower part of the inner box 3 is provided with a grid vibrating plate 31 sliding up and down, and the grid vibrating plate 31 is connected with the inner box 3 through a vibrating assembly. The second bearing that connects, the insid...

Embodiment 2

[0043] Embodiment 2: In Embodiment 1, there is also the problem that the vibrating effect of the grid vibrating plate is not good. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0044] In the present invention, see Figure 8 , the vibrating assembly includes a vibrating shaft 35 and an eccentric cam 36. A vibrating shaft 35 placed longitudinally in the middle of the inner box 3 under the grid vibrating plate 31 is located on the front and rear inner walls of the inner box 3 at the front and rear ends of the vibrating shaft 35. First bearings are arranged on the top, and the two ends of the vibration shaft 35 are respectively inserted in the corresponding first bearings, and the front end of the vibration shaft 35 penetrates the inner box 3 and extends to the front of the inner box 3, and is located in the inner box 3. A pair of eccentrically fixed eccentric cams 36 are sleeved on the inner vibrating shaft 35, and the top of each eccentric cam 36 is i...

Embodiment 3

[0046] Embodiment three: in embodiment one, also there is the problem that water control is slow and air-drying effect is poor after seed infiltration operation is finished, therefore, on the basis of embodiment one, this embodiment also includes:

[0047] In the present invention, see figure 2 and image 3 Rectangular ventilation holes 33 are provided at the bottom of both sides of the inner box 3 under the grid vibrating plate 31, and a pair of circular through-holes are provided at the top of both sides of the bottom box 11, and the inside of each circular through-hole is Concentric fan rings 27 are fixed, each fan ring 27 is equipped with a fan 28 with the output wind direction inward, the model of the fan 28 is 3414NH, and the outer port of each fan ring 27 is equipped with a dustproof Cover 29; the middle and upper part of the left side of the bottom box 11 is provided with a water injection pipe 17 that penetrates and is fixed in a horizontal direction, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com