Wart freezing cutting device for dermatology department

A cutting device and dermatological technology, applied in the field of medical devices, can solve the problem of no wart freezing and peeling, and achieve the effect of clear design, quick freezing and cutting, and avoiding volatilization and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

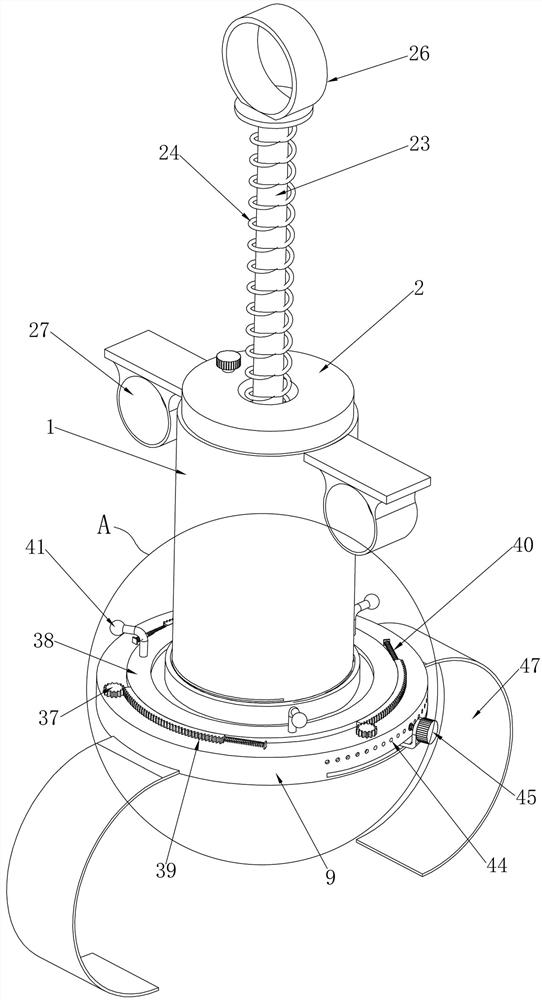

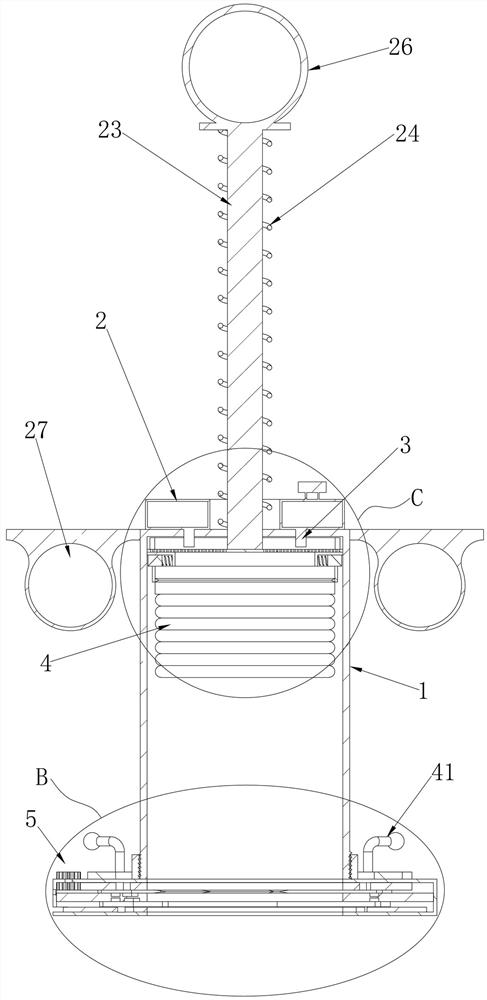

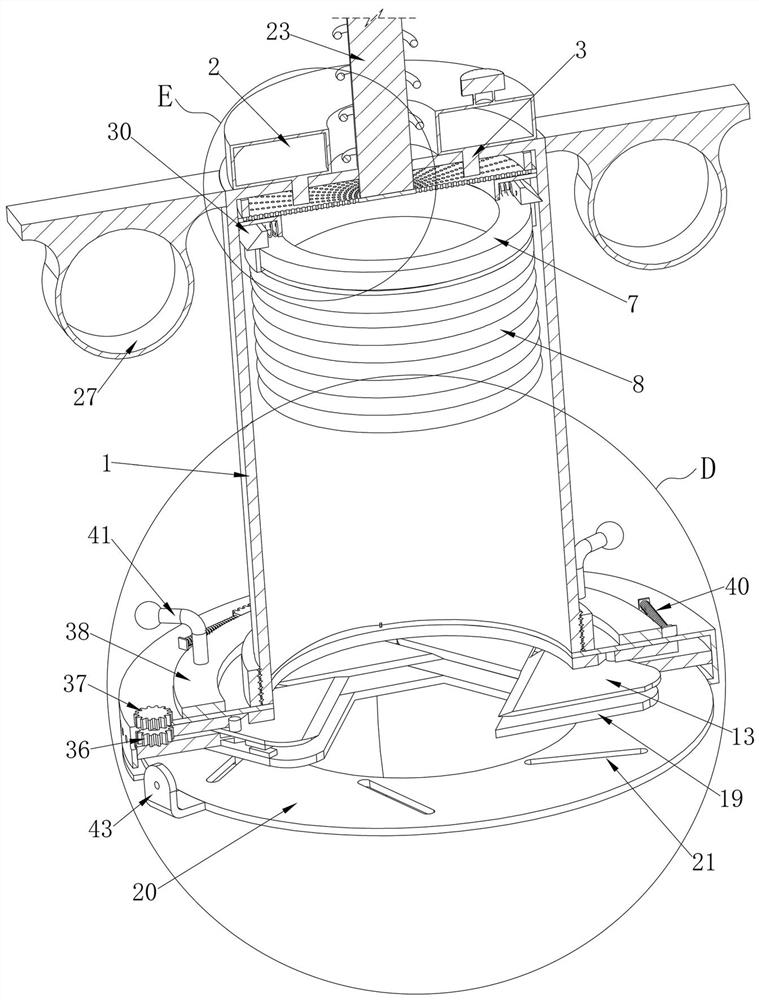

[0043]Embodiment 1, the present invention is a wart cryocutting device for dermatology, which includes a cylinder 1 with an inner hollow and an open bottom. The material of the cylinder 1 can be made of stainless steel, and a cotton cloth layer can be wrapped outside the cylinder 1. During operation, the cotton cloth layer can be held by hand. The top of the cylinder body 1 is fixedly equipped with a ring-shaped and internally hollow liquid nitrogen ring 2. The top of the liquid nitrogen ring 2 is equipped with a liquid inlet, which can be imagined as a liquid nitrogen ring. 2. Liquid nitrogen is injected into the interior for storage. The bottom of the liquid nitrogen ring 2 is connected with a push valve 3 that runs through the top of the cylinder 1 and is located inside the cylinder 1. The push valve 3 is located in the cylinder 1 and can be activated by pressing the push valve Liquid nitrogen flows into the cylinder body 1, and a freezing device 4 is installed sliding up an...

Embodiment 2

[0046] Embodiment two, on the basis of embodiment one, as attached Figure 11 As shown, the bottom surface of the chute ring 10 is provided with a clamping chute 17 corresponding to the position and shape of a plurality of cutting chute 11, each of the clamping chute 17 is slidably installed with a clip Hold sliders 18, the bottom of each of the clamp sliders 18 is fixedly connected with a clamping plate 19 that is triangular and one of its sides faces the axis of the cutting ring 9, and the initial positions of a plurality of clamping plates 19 are Located inside the cutting ring 9, and below the plurality of cutting blades 13, and close to the bottom of the cutting ring 9, when a plurality of clamping sliders 18 slide in the clamping chute 17 at the same time, they can drive a plurality of clamping plates 19 moves to the axial center of cutting ring 9 at the same time, the space between the sides of a plurality of clamping plates 19 becomes smaller gradually, thereby can cla...

Embodiment 3

[0048] Embodiment 3, on the basis of Embodiment 1, the top of the pressing screen 6 is coaxially fixedly connected with a pressing rod 23 that runs through the top of the cylinder 1, and the pressing rod 23 can drive the pressing screen 6 inside the cylinder 1 Moving up and down, the pressing rod 23 is covered with a pressing spring 24 between the top and the top of the cylinder 1. When the pressing rod 23 moves to the inside of the cylinder 1, the pressing spring 24 can be compressed. Under the effect of upward reset, the top edge of the pressing net plate 6 is fixedly connected with a rubber ring 25. When the pressing net plate 6 is in the initial position, the top of the rubber ring 25 is close to the top of the cylinder body 1. At this time, the pressing net plate 6 is not in contact with the pressing valve 3. When the sponge 8 needs to absorb liquid nitrogen, the pressing rod 23 can be lifted upwards, so that when the pressing net plate 6 moves upward, the rubber ring 25 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com