Centrifugal gas multi-stage filtering device

A stage filtration and centrifugal technology, which is applied in the field of centrifugal gas multi-stage filtration devices, can solve the problems of reduced performance, equipment breakdown, dust stickiness, etc., and achieve the effects of improving performance, prolonging service life and preventing dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

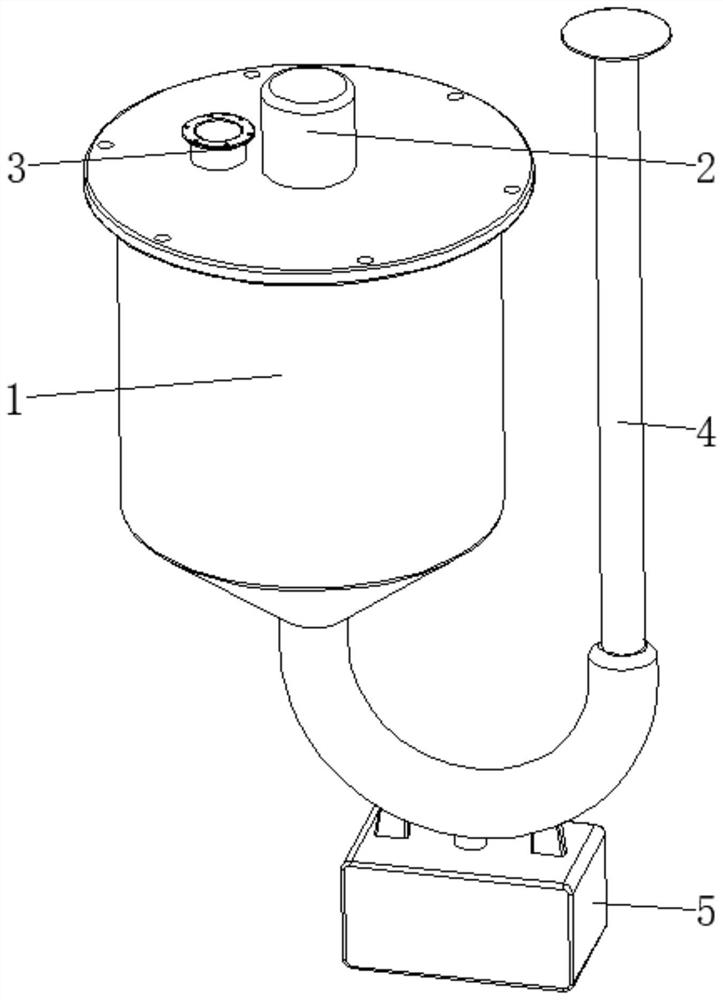

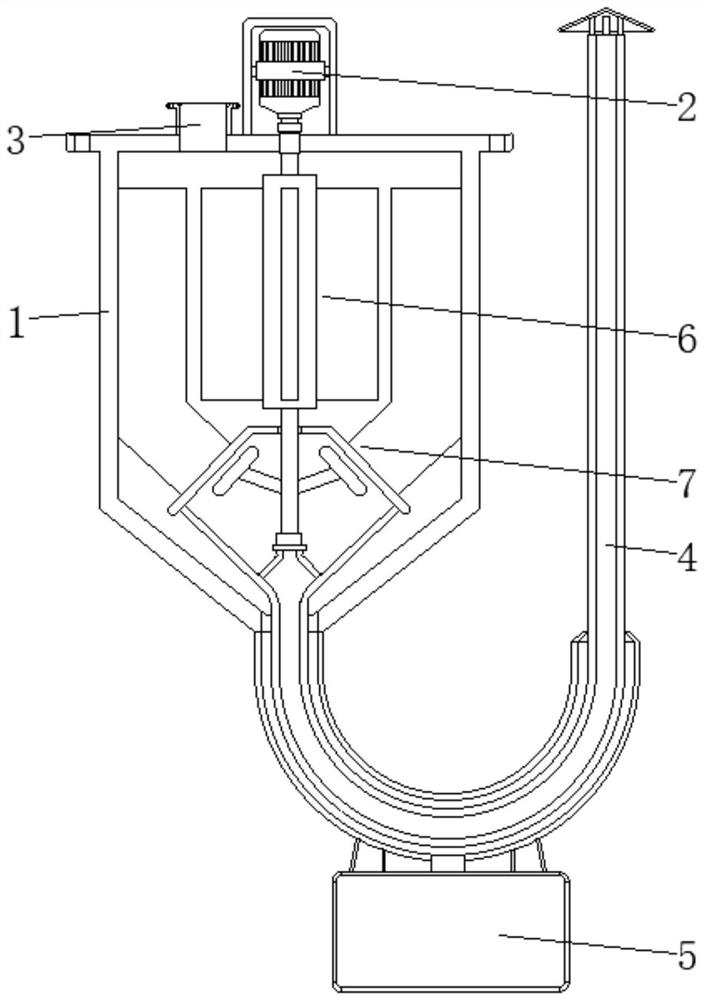

[0029] see Figure 1-6 , the present invention provides a technical solution: a centrifugal gas multi-stage filter device, including a housing 1, a driving mechanism 2, an air inlet 3, a trumpet exhaust pipe 4, and a vacuum cleaner 5, and the driving mechanism 2 is arranged on the housing 1, the air inlet 3 is set on the top of the casing 1 and close to the driving mechanism 2, the bell mouth exhaust pipe 4 is set at the bottom of the inner wall of the casing 1 and extends to the outside, and the vacuum cleaner 5 is set on the casing the bottom of body 1;

[0030] The interior of the housing 1 is provided with a stirring device 6 and a multi-stage filtering device 7. The stirring device 6 is arranged at the inner center of the housing 1 and near the top position, and the multi-stage filtering device 7 is arranged inside the housing 1, and the multi-stage filtering The device 7 is connected with the stirring device 6, and the gas is passed into the housing 1 through the air in...

Embodiment example 2

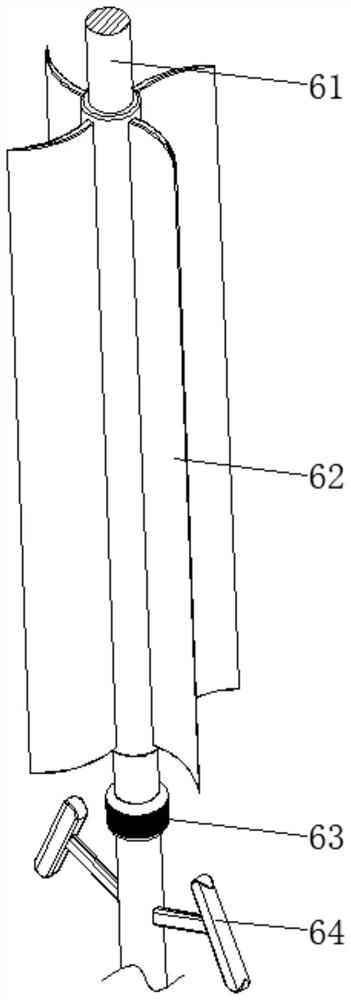

[0032] The agitating device 6 is provided with a rotating shaft 61, an arc fan blade 62, a sealing sleeve 63, and a toggle member 64. The surface top of the rotating shaft 61 is rotatably connected to the inner top of the housing 1, and the arc fan blade 62 is fixed on the surface top of the rotating shaft 61. The sealing sleeve 63 is disposed on the surface of the rotating shaft 61 and close to the bottom of the arc-shaped blade 62 , and the toggle member 64 is disposed on the bottom of the rotating shaft 61 and close to the sealing sleeve 63 .

[0033] The multi-stage filtering device 7 is provided with a conical secondary filter screen 71, a primary filter plate device 72, and an elastic knocking device 73. The inner wall of the conical secondary filter screen 71 is fixedly connected with the end of the bell mouth exhaust pipe 4, and the primary filter The plate device 72 is arranged between the two sides corresponding to the surface of the conical secondary filter screen 71...

Embodiment example 3

[0035]The primary filter plate device 72 is provided with a filter plate 721, a first rubber strip 722, and a second rubber strip 723. The filter plate 721 is arranged inside the housing 1 and is close to the conical secondary filter screen 71. The first rubber strip 722 Set on the edge of the surface of the filter plate 721 and fixedly connected with the inner wall of the housing 1, the second rubber strip 723 is set at the bottom of the filter plate 721 and fixedly connected with the surface of the conical secondary screen 71, when the conical secondary When the primary filter screen 71 is hit and vibrates, the flexibility of the first rubber strip 722 and the second rubber strip 723 is used, and the filter plate 721 will shake continuously at this time, which is convenient for particle dust to fall off. The effect, but also achieved the purpose of self-cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com