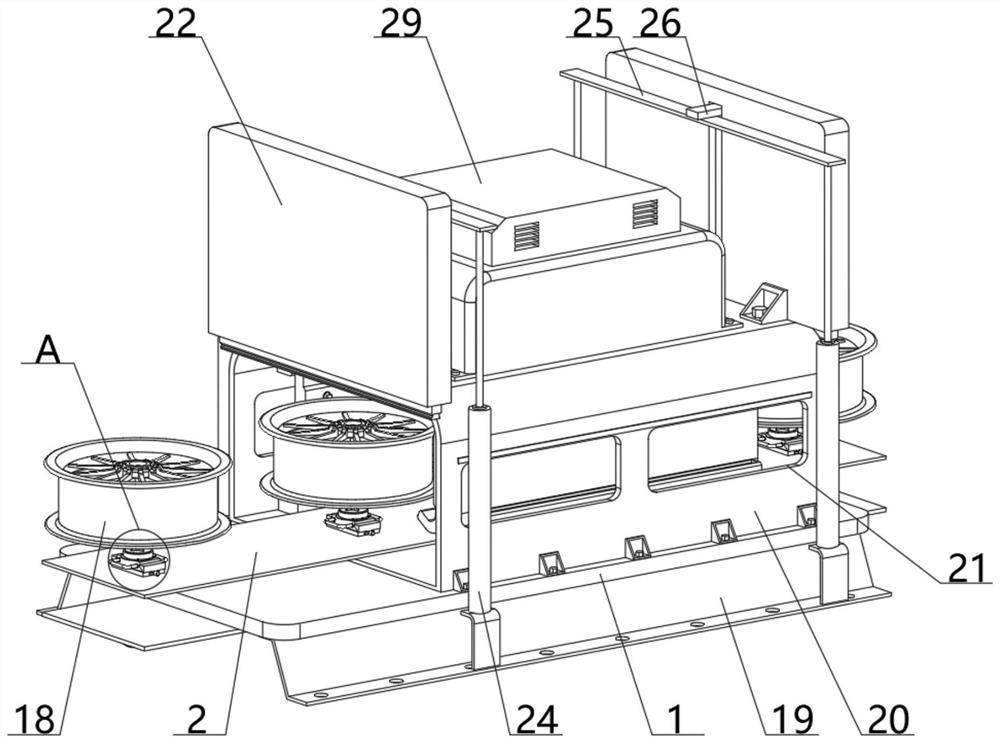

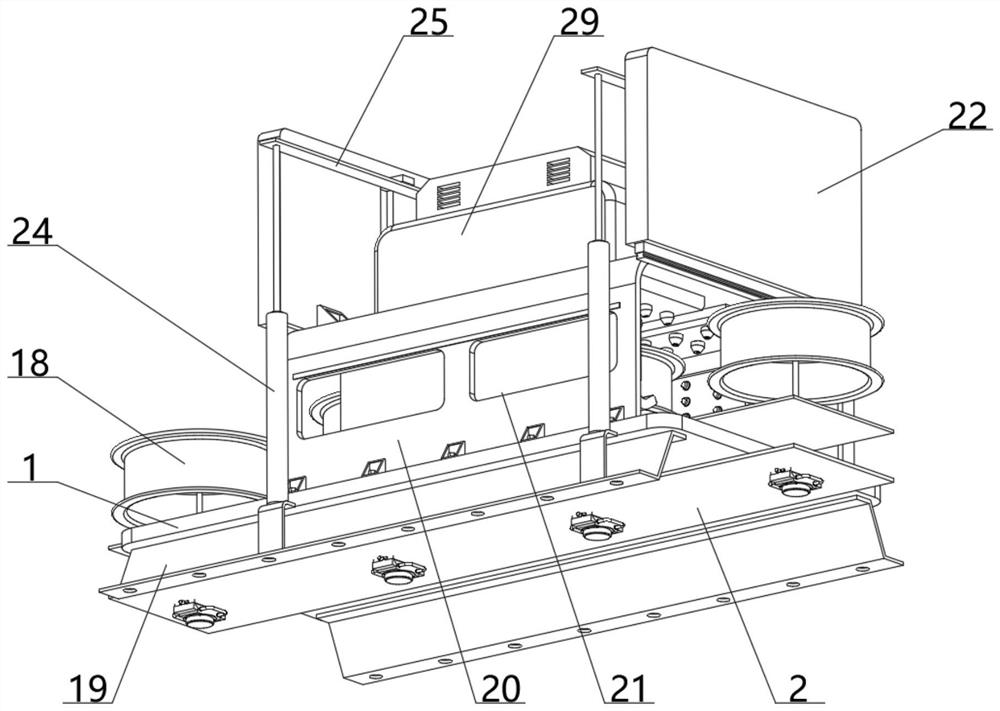

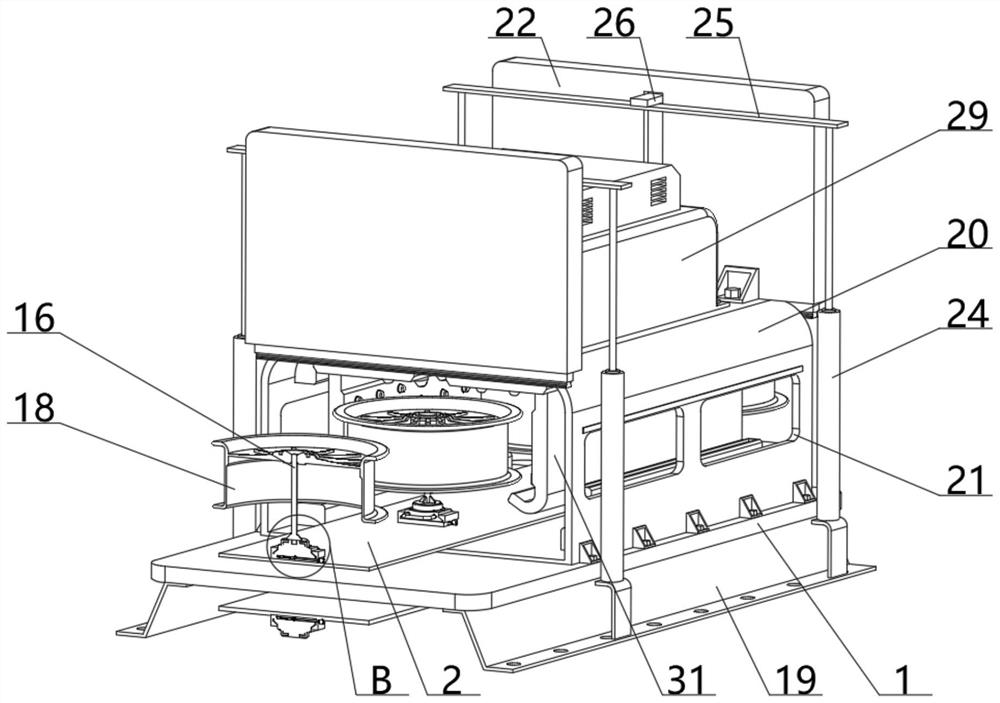

High-gloss low-film-thickness aluminum alloy hub spraying process and spraying device

A technology of aluminum alloy wheel hub and spraying device, which is applied in spraying device, device for coating liquid on the surface, coating and other directions, can solve the problem of reducing the efficiency of wheel hub painting operation, low degree of wear resistance and corrosion resistance of wheel hub, and no external impurity barrier. and other problems to achieve the effect of improving the efficiency of painting operations, improving the convenience of disassembly and assembly, and improving the convenience of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A spraying process of a high gloss and low film thickness aluminum alloy wheel hub spraying device, comprising the following steps:

[0063] A: Pretreatment of the surface of the automobile wheel hub: before the painting operation of the automobile wheel hub, the wheel hub is placed in a degreasing solution for treatment, and the oil stains or liquids left during the production and processing of the wheel hub surface are removed, which can effectively remove the grease and impurities on the wheel hub surface , the degreasing solution is an aqueous solution containing 6% sodium salt, surfactant and cleaning agent by weight, and the weight ratio of sodium salt, surfactant and cleaning agent is 9: 11: 66. During the pretreatment of the hub surface , Derusting the surface of the hub by sandblasting or sandpaper grinding;

[0064] B: Preparation before painting of automobile wheel hubs: After the surface pretreatment of automobile hubs is completed, place the hubs in dilute ...

Embodiment 2

[0074] A spraying process of a high gloss and low film thickness aluminum alloy wheel hub spraying device, comprising the following steps:

[0075] A: Pretreatment of the surface of the automobile wheel: before the painting operation of the automobile wheel, place the wheel in a degreasing solution to remove the oil or liquid remaining on the surface of the wheel during production and processing. The degreasing solution contains 10% by weight The aqueous solution of sodium salt, surfactant and cleaning agent, the weight ratio of sodium salt, surfactant and cleaning agent is 12:16:71, which can effectively remove the grease and impurities on the surface of the hub. During the pretreatment process of the surface of the hub , Derusting the surface of the hub by sandblasting or sandpaper grinding;

[0076]B: Preparation before painting of automobile wheel hubs: After the surface pretreatment of automobile hubs is completed, place the hubs in dilute lye for soaking treatment. The m...

Embodiment 3

[0086] A spraying process of a high gloss and low film thickness aluminum alloy wheel hub spraying device, comprising the following steps:

[0087] A: Pretreatment of the surface of the automobile wheel hub: before the painting operation of the automobile wheel hub, the wheel hub is placed in a degreasing solution for treatment, and the oil stains or liquids left during the production and processing of the wheel hub surface are removed. The degreasing solution contains 15% by weight The aqueous solution of sodium salt, surfactant and cleaning agent, the weight ratio of sodium salt, surfactant and cleaning agent is 16:22:77, which can effectively remove the grease and impurities on the surface of the hub. During the pretreatment process of the surface of the hub , Derusting the surface of the hub by sandblasting or sandpaper grinding;

[0088] B: Preparation before painting of automobile wheel hubs: After the surface pretreatment of automobile hubs is completed, place the hubs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com