Chemical fiber medical belt online winding and hot cutting automation equipment and use method

A technology of automated equipment and medical belts, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of low overall efficiency, manual disconnection, manual feeding and discharging, etc., to reduce labor intensity. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

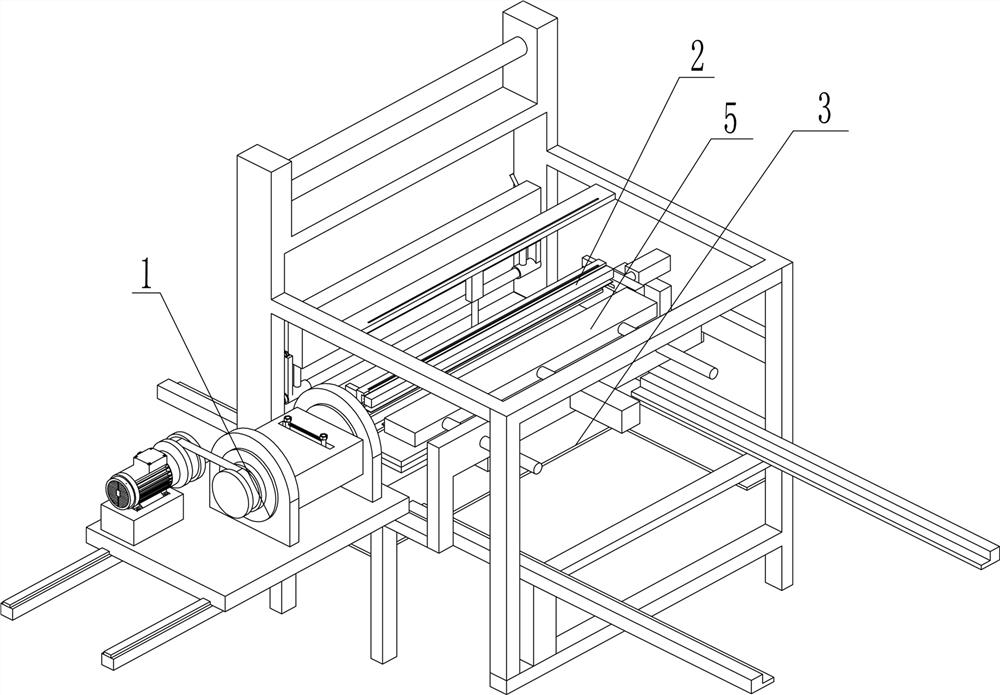

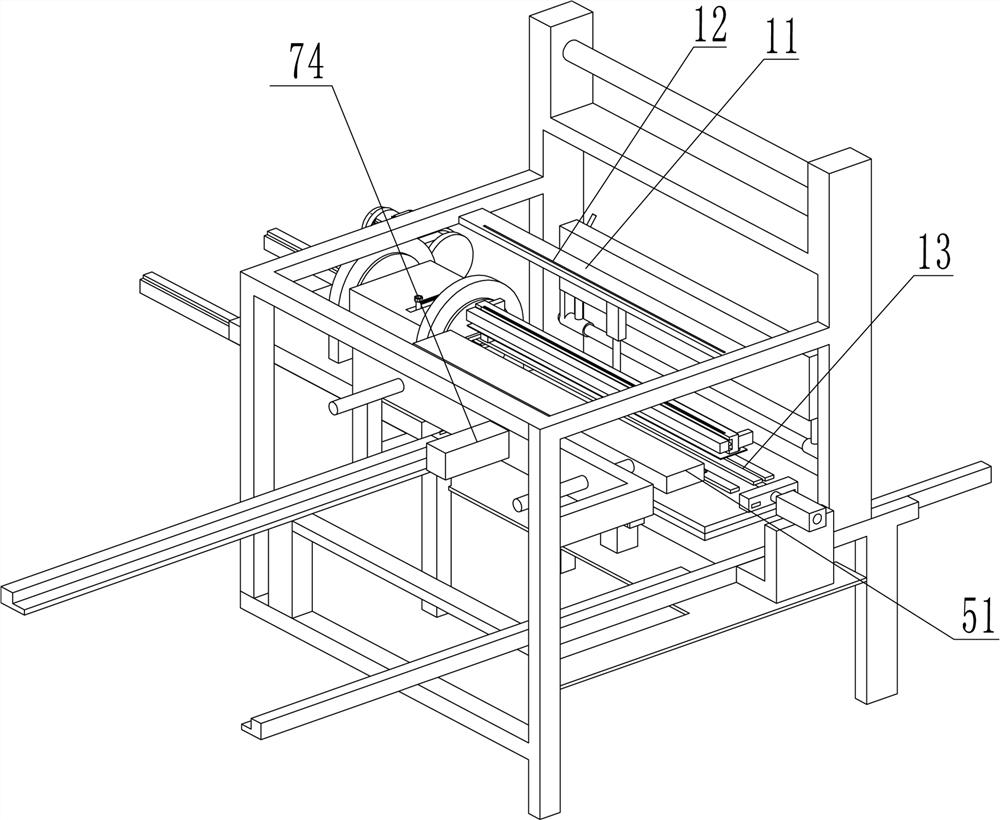

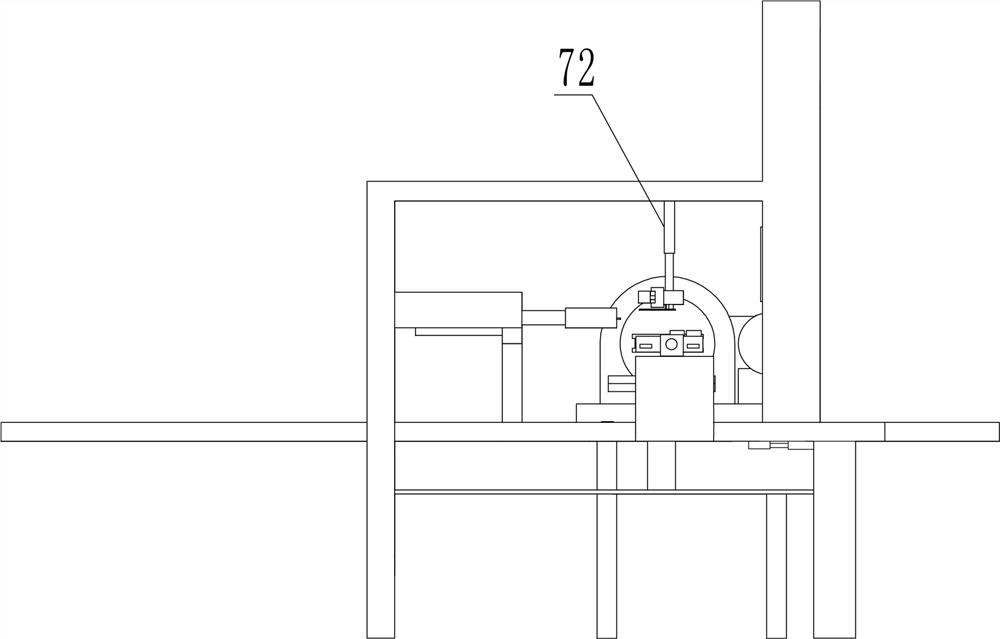

[0048] like Figure 1~Figure 8Among them, a chemical fiber medical tape on-line winding and eagerly cutting automation equipment includes a frame, a support plate 11 is connected to the upper part of the frame, and a medical tape slot 12 is opened on the surface of the support plate 11; the inner wall of the frame above the support plate 11 is connected with guide rollers ; A winding mechanism 1 is connected to the side of the frame, and a collet 13 is connected to the end of the winding mechanism 1; a feeding device 2 is connected to the bottom of the support plate 11, and the feeding device clamps the medical belt passing through the medical belt slot 12; The collet The surface of the frame below 13 is connected with a discharging device 3; the inner wall of the frame on one side of the winding mechanism 1 is connected with an eager cutting device 5, and the inner wall of the frame on the other side of the winding mechanism 1 is connected with a support rod 61, and the outer ...

Embodiment 2

[0066] like Figure 9 As shown in the figure, the whole equipment cooperates with the belt loom 8, and a groove-shaped multi-channel material storage buffer device 9 is arranged between the belt loom 8 and the equipment. The surface of the multi-channel material storage buffer device 9 is divided into a plurality of grooves by a partition The 12 channels and 24 medical belts drawn from the belt weaving machine 8 are separated by the multi-channel storage device. Multiple medical belts bypass the tension roller 91 and then dock to the equipment, bypass the guide roller, and then lead to the medical belt card. The groove 12 is passed downwards out of the medical belt clamping groove 12 and then led to the feeding device 2 for clamping, so as to realize the simultaneous winding of multiple medical belts.

Embodiment 3

[0068] The above-mentioned use method of the chemical fiber medical tape on-line winding eagerly cutting automatic equipment comprises the following steps:

[0069] S1, connect the equipment as a whole with the tape weaving machine 8, and the woven medical tapes are drawn out from the tape weaving machine 8 and then bypass the guide rollers, then pass through the medical tape card slot 12, and then pass through the feeding material in the feeding device 2. The troughs opened on the surface of the plate 21 and the bottom plate 23;

[0070] S2, the winding mechanism 1 slides under the drive of the driving mechanism, so that the fixed clamping plate 41 and the sliding clamping plate 42 of the collet 13 are in the clamping position, and then the telescopic mechanism inside the rotating member 15 is activated, so that the sliding clamping plate 42 faces the side of the fixed clamping plate 41 action to clamp the end of the medical belt exposed below the feeding device 2;

[0071] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com