Polyolefin composition as well as preparation method and application thereof

A technology of polyolefin and composition, which is applied in the field of polyolefin composition and its preparation, can solve the problems such as the decline of mechanical properties of materials, and achieve the effect of good spraying performance and improved spraying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of the polyolefin composition in described embodiment and comparative example, comprises the steps:

[0054] S1. Mix the polyolefin resin, toughening agent, mineral filler, lubricant and antioxidant evenly, and add the expanded perlite powder to the side feeding port of the extruder through an independent metering feeding scale to obtain a premix;

[0055]S2. Extruding and granulating the premix in step S1 to obtain a polyolefin composition. The extrusion processing temperature is 190°C to 230°C.

Embodiment 1~5

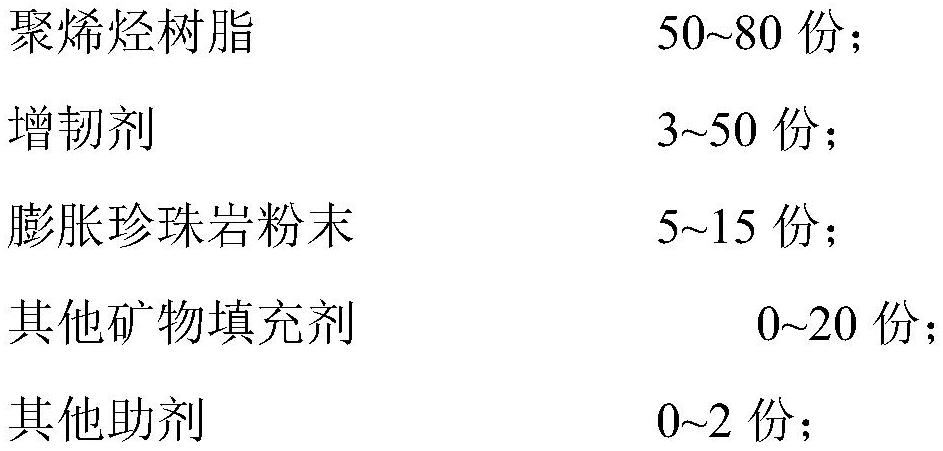

[0057] Examples 1-5 provide a series of polyolefin compositions, and the contents of specific components are shown in Table 1.

[0058] The component content (part) of table 1 embodiment 1~5

[0059]

[0060]

Embodiment 6~10

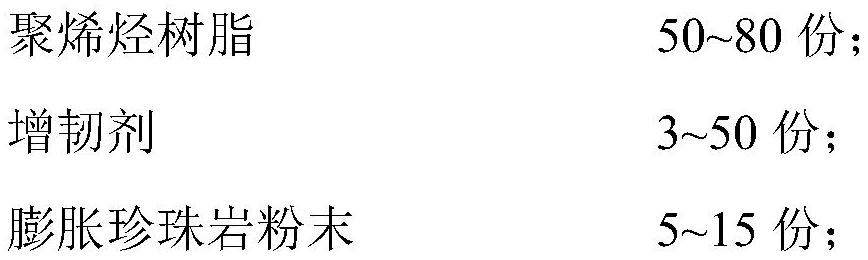

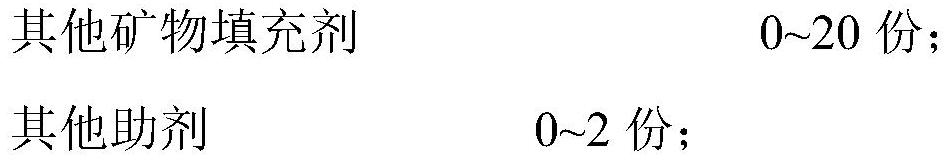

[0062] Examples 6-10 provide a series of polyolefin compositions, and the contents of specific components are shown in Table 2.

[0063] The component content (part) of table 2 embodiment 6~10

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com