Metal part heat treatment process

A technology of metal parts and heat treatment devices, which is applied in the field of heat treatment, can solve the problems of low production efficiency, inability to replace quenching liquid, and affect the effect of heat treatment, etc., to achieve the effect of improving safety, improving functionality, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

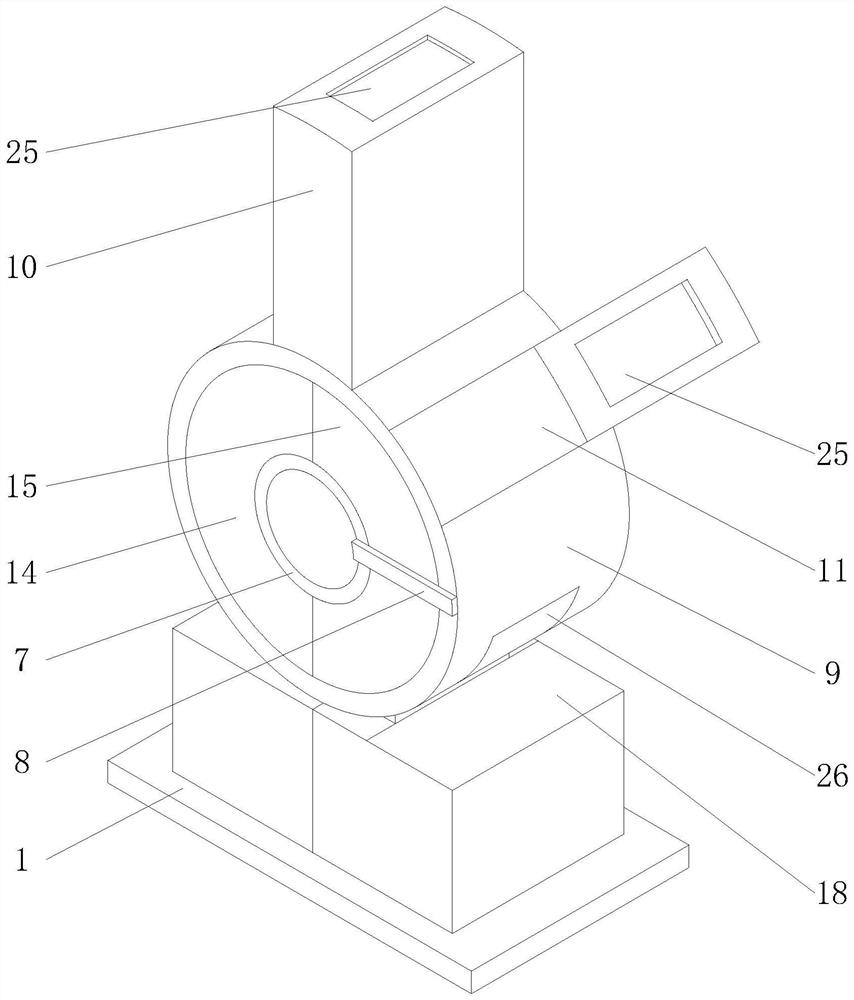

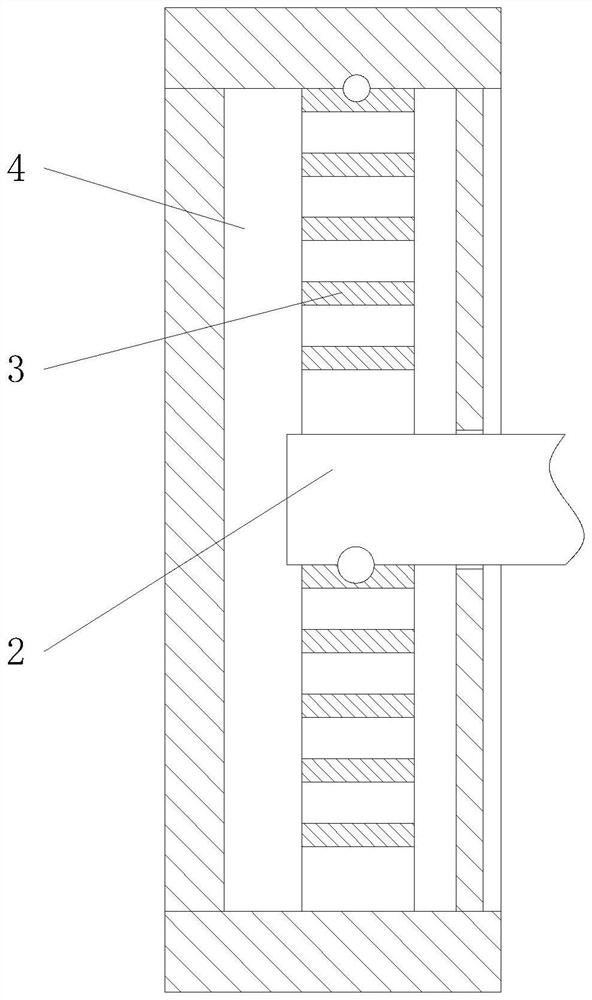

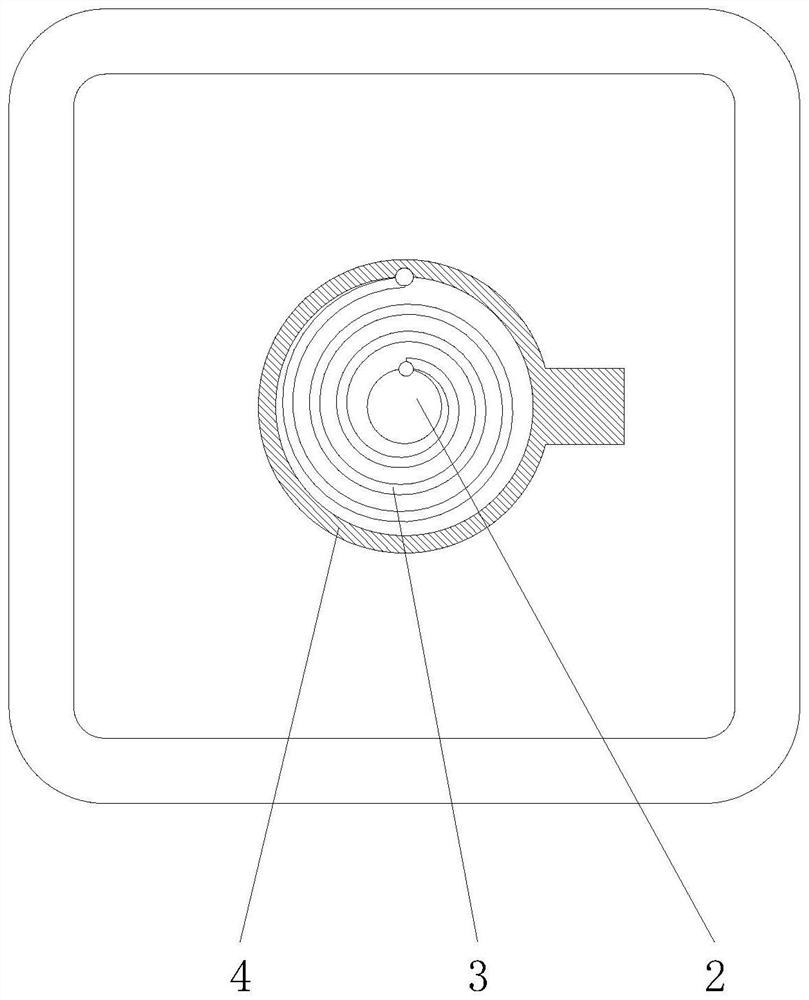

[0038] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0039] Such as Figure 1-7 Shown, a metal parts heat treatment process, comprising the following steps:

[0040]A. Adding liquid: by adding quenching liquid to the interior of the metal parts heat treatment device, the preparation work before heat treatment and quenching is completed;

[0041] B. Quenching the workpiece: through the suspension device, the metal parts are lowered into the quenching liquid for quenching heat treatment;

[0042] C. Automatic replacement of quenching liquid: to replace the quenching liquid, discharge the used quenching liquid at the same time, and then automatically add the quenching liquid to the empty box;

[0043] D. Protect the heat treatment device of metal parts: In the process of replacing the quenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com