Steel structure trestle with extension frame and implementation method of steel structure trestle

A technology for steel structures and trestles, applied in the field of steel structure trestles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

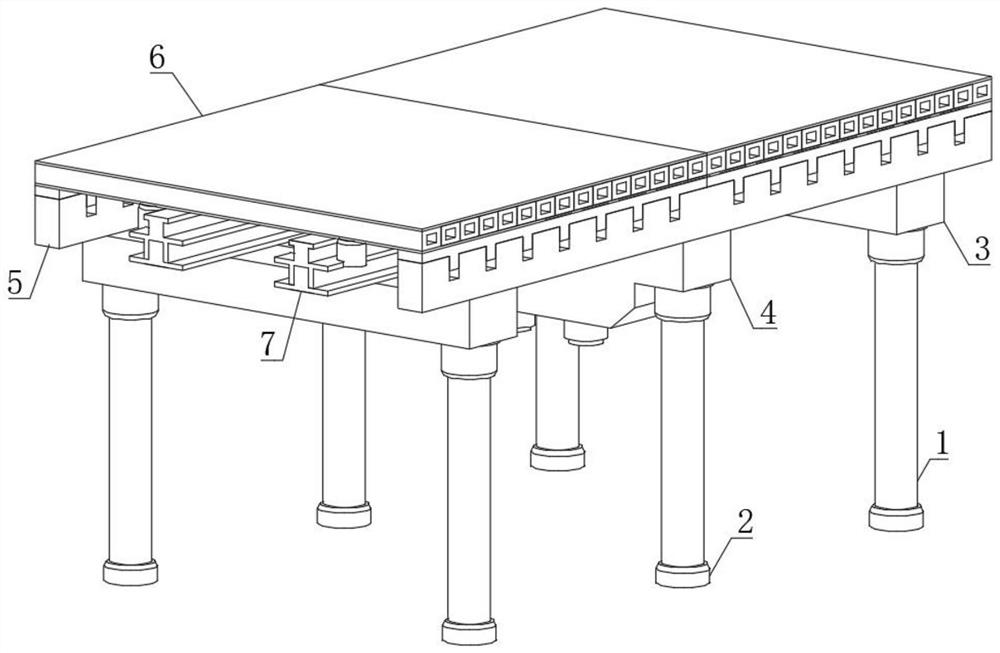

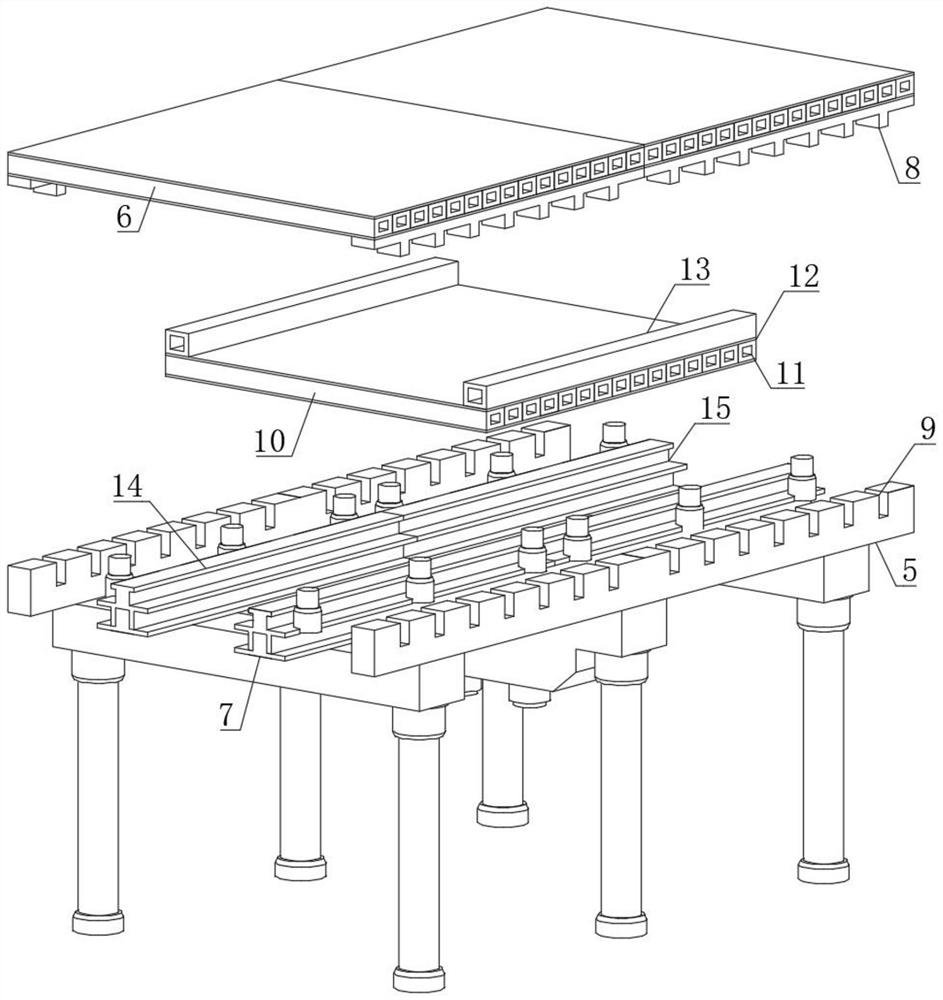

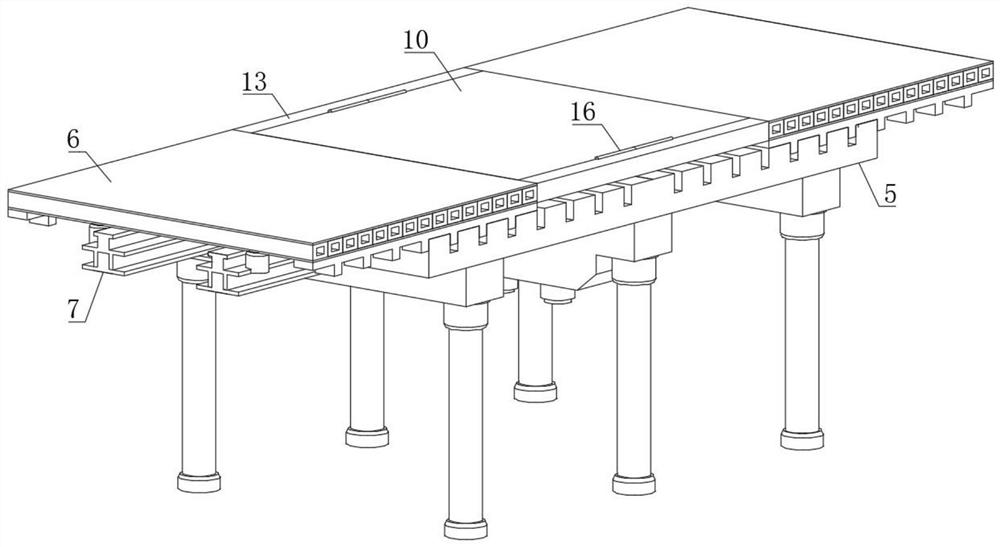

[0036] A method for implementing a steel structure trestle bridge with an extended frame, comprising the steps of:

[0037] Step 1: Nail trestle pillars 1 into the construction area according to the specified spacing. After the trestle pillars 1 are fixed and horizontally corrected, the central cross bridge 4 is hoisted above the middle pillars and anchored, and then the traditional The supporting cross bridge 3 is hoisted above other pillars;

[0038] Step 2: Control the lifting strut 24 in the middle section of the central cross bridge 4 to rise, then suspend the central lifting plank 10 above the lifting strut 24, and place the central lifting strut 10 horizontally on the top of the lifting strut 24, and fix After that, the lifting pole 24 is lowered and reset, and now the central lifting plank road 10 will descend together with the lifting pole 24, and keep the same horizontal height as the central cross bridge 4;

[0039] Step 3: Fix the four sets of extended misaligned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com