Glued board for container floor

A technology for container floor and plywood, applied in the field of plywood, can solve problems such as shortage and floor cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

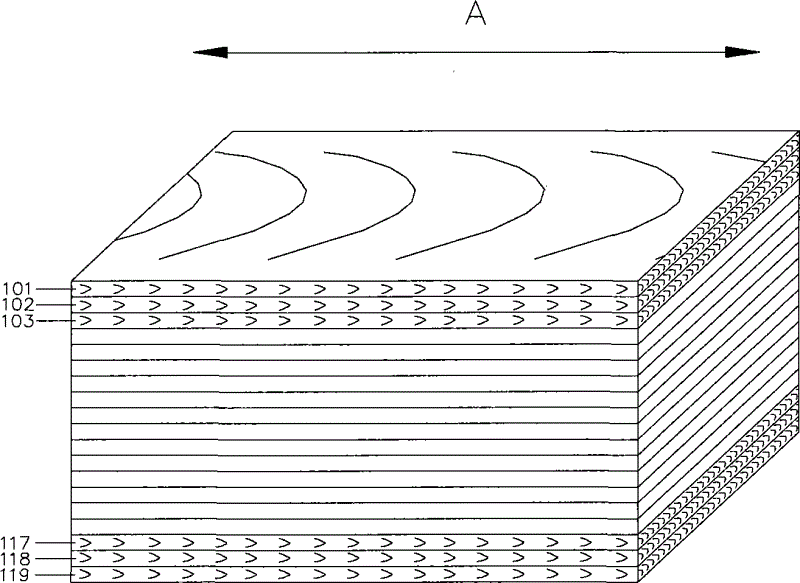

Embodiment 1

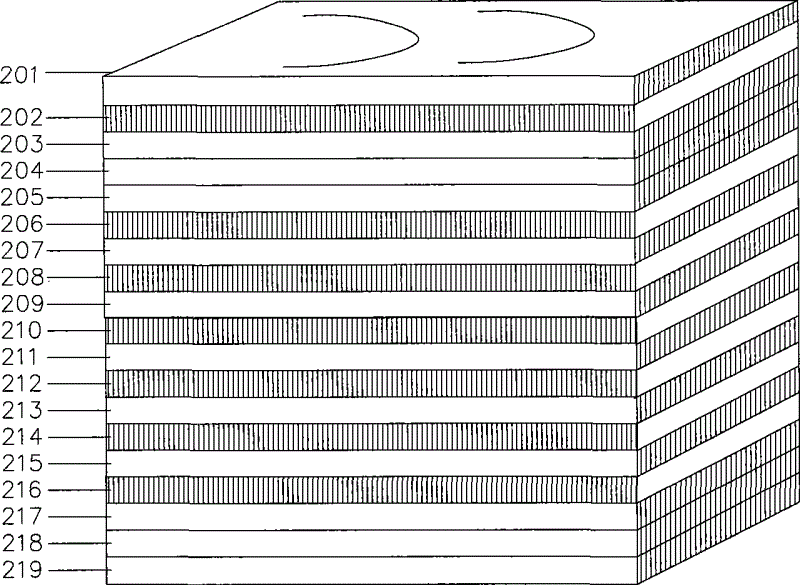

[0020] Such as figure 2 As shown, a plywood for the bottom plate of a container has an asymmetric structure of 19 layers. The first layer panel 201 on the outermost surface is a long veneer along the grain, the second layer panel 202 is a horizontal grain short medium plate, and the third layer panel 203 is a long middle board along the grain, and the core boards 204 and 205 adjacent to the third layer panel 203 are long middle boards along the grain; Along the grain long medium plate; and other core plates: along the grain long medium plate 207, 209, 211, 213, 215 and horizontal grain short medium plate 206, 208, 210, 212, 214, 216 are arranged in a criss-cross pattern; the above Adjacent plies are joined by pressing and gluing.

Embodiment 2

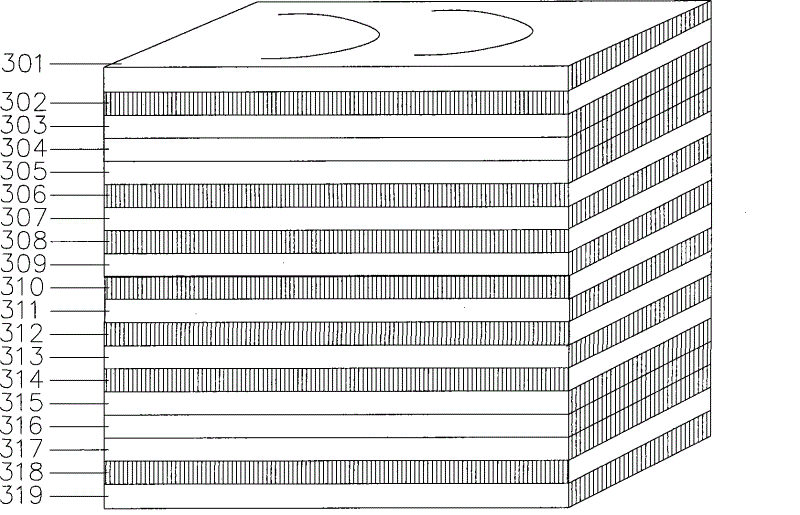

[0022] Such as image 3 As shown, the board has a 19-layer symmetrical structure. In this example, the first layer panel 301 on the outermost layer is a long veneer along the grain, the second layer panel 302 is a short and medium board with horizontal grain, and the third layer panel 303 is a long veneer along the grain. veneer, the core boards 304 and 305 adjacent to the third layer panel 303 are long middle boards along the grain; the first bottom board 319 at the bottom is a long single board along the grain, and the second bottom board 318 is a short middle board with horizontal grains , the third bottom plate 317 is a long veneer along the grain, and the core plates 316, 315 adjacent to the third bottom plate 317 are long middle plates along the grain; and other core plates: long middle plates 307, 309, 311, 313 and cross-grain short and medium plates 306, 308, 310, 312, 314 are arranged in a criss-cross pattern, and the above adjacent plates are connected by pressing an...

Embodiment 3

[0024] Such as Figure 4 As shown, the difference between this example and Example 1 is that a layer of thermosetting impregnating material 42 is compounded on the first panel 201 of the board, and the thermosetting impregnating material can be phenolic glue or melamine glue impregnating material.

[0025] Similarly, a layer of thermosetting impregnating material can also be compounded on the first layer of Example 2, and the thermosetting impregnating material can be phenolic glue or melamine glue impregnating material.

[0026] Based on known technologies in the art, the number of veneer layers that make up the plywood for the bottom plate of a container can be an odd number of 15 to 21 layers, so the 19 layers in the above examples are only for illustration, and the embryo formation methods of other layers are not described here. Let me repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com