Connection clapboard of combined PVC (Poly Vinyl Chloride) building template and manufacture method thereof

A building template and combined technology, which is applied in the direction of buildings, building components, building materials, etc., can solve the problem of no new breakthroughs in use functions, and achieve the effects of increasing lateral tension, improving safety performance, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

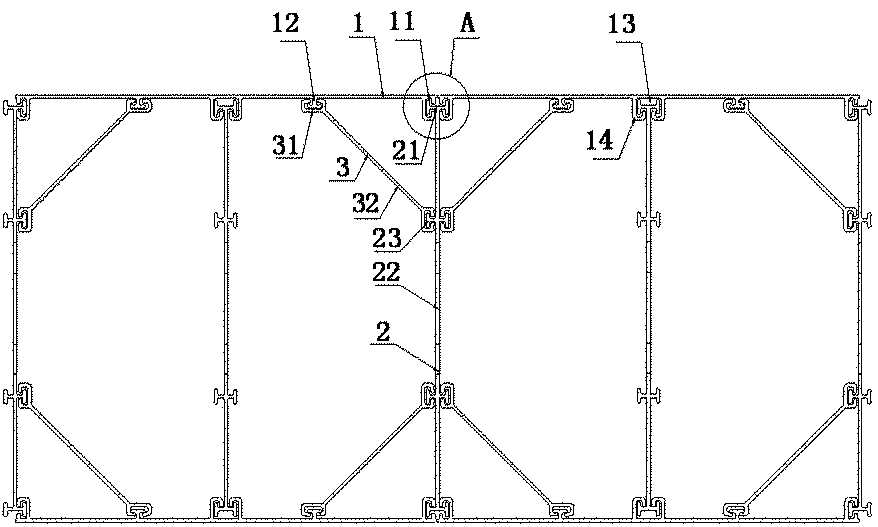

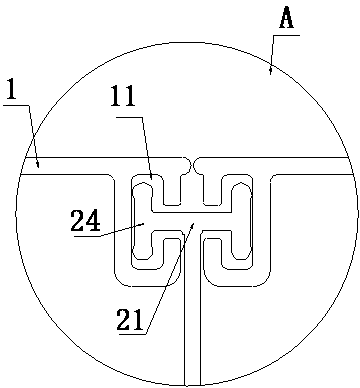

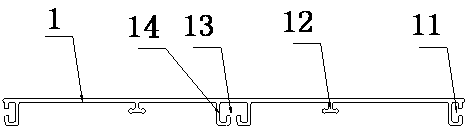

[0044] Such as figure 1 As shown in the combined PVC building template, the building template includes a panel 1, a connecting partition 2 and a rib plate 3. Such as image 3 As shown, the two ends of the panel 1 are respectively provided with a first "C"-shaped connecting groove 11 towards the inside, and the middle part of the connecting partition 2 is provided with a main reinforcement opening 22 . Figure 4 , Figure 5 As shown, the two ends of the connecting partition 2 are respectively provided with an I-shaped connector 21 , and the I-shaped connector 21 has two first “T”-shaped connecting rails 24 . Such as figure 2 As shown, the two first "T"-shaped connecting rails 24 connecting one end of the partition plate 2 are respectively buckled in the first "C"-shaped connecting grooves 11 of the two inner panels 1 to connect the two inner panels 1. Integrated, the two first "T"-shaped connecting rails 24 at the other end are respectively buckled in the first "C"-shaped ...

Embodiment 2

[0068] Such as Figure 8 , Figure 9 The connecting partition 2 of the combined PVC building formwork is shown. The thickness of the connecting partition 2 is 3mm. Connecting head 21, I-shaped connecting head 21 has two "T"-shaped connecting rails 24, and the other end is provided with connecting groove 26, and connecting groove 26 is formed by two "J"-shaped sections 27. In addition, "T"-shaped connecting rails 23 are provided on the two sides of the middle part of the connecting partition 2, and the connecting partition 2 is made by extrusion molding of the following materials (the preparation method is as described in Example 1):

[0069] PVC resin SG-5 100 parts calcium zinc stabilizer 3.5 parts

[0070] Light CaCO 3 6 parts DuPont titanium dioxide 9 parts

[0071] Impact modifier CPE 10 parts UV absorber UV 0.5 parts

[0072] Enhancer ACR 2 parts;

[0073] The main reinforcement opening 22 is punched by a punching machine.

Embodiment 3

[0075] Such as Figure 10 , Figure 11 The connecting partition 2 of the combined PVC building formwork shown, the thickness of the connecting partition 2 is 3mm, the middle part of the connecting partition is provided with the main reinforcement opening 22, and one side of the connecting partition 2 is provided with the first Reinforced opening 25. And one end of the connecting partition 2 is provided with an I-shaped connector 21, the I-shaped connector 21 has two "T"-shaped connecting rails 24, and the other end is provided with a connecting groove 26, and the connecting groove 26 consists of Two " J " profile sections 27 constitute. In addition, "T"-shaped connecting rails 23 are provided on the two sides of the middle part of the connecting partition 2, and the connecting partition 2 is made by extrusion molding of the following materials (the preparation method is as described in Example 1):

[0076] PVC resin SG-5 100 parts Calcium zinc stabilizer 6.5 parts

[0077]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com