Concentricity detection method and device

A detection method and detection device technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of misalignment of large and small heat sink oil bags, too subjective judgment, low work efficiency, etc., to avoid the lack of objectivity , Improve product quality and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

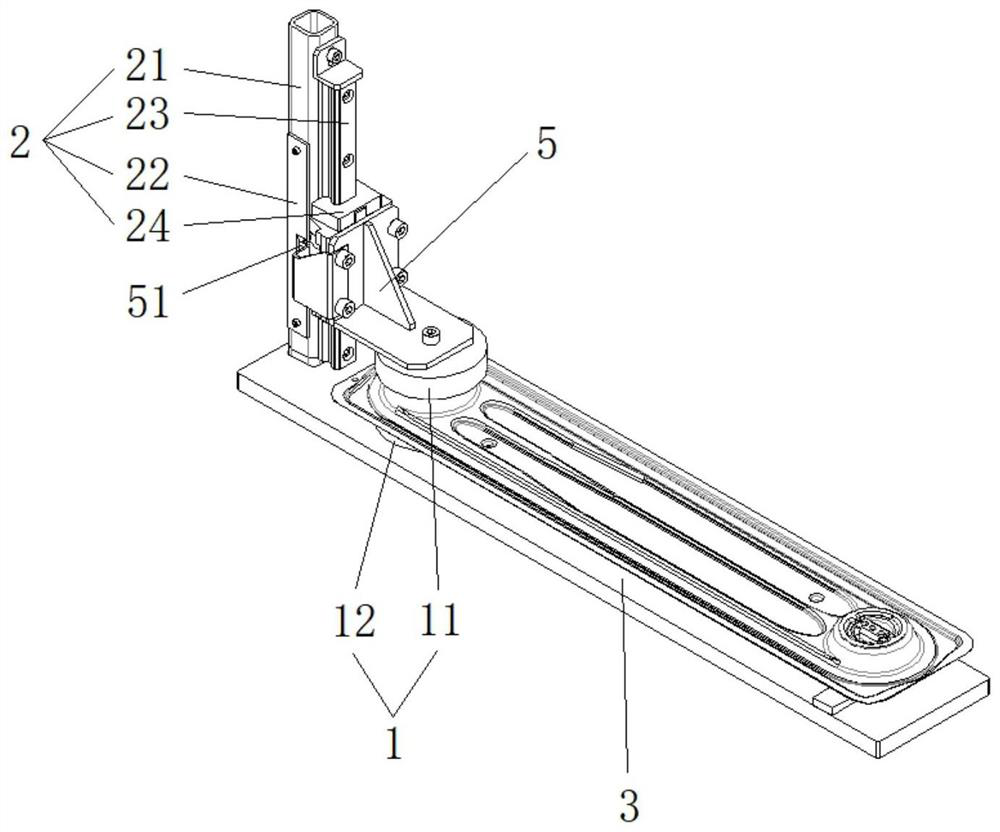

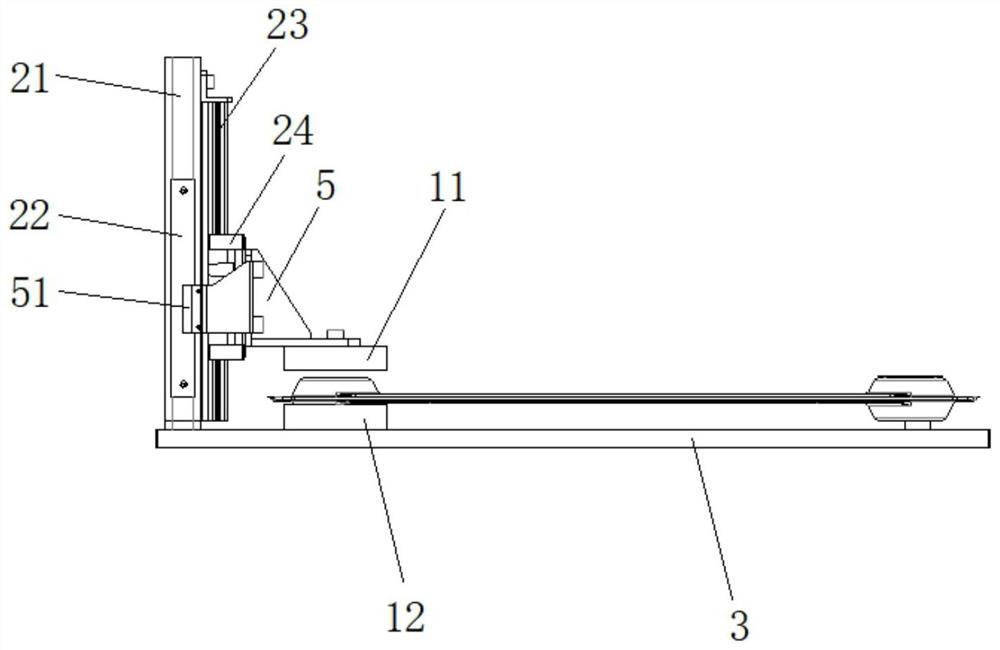

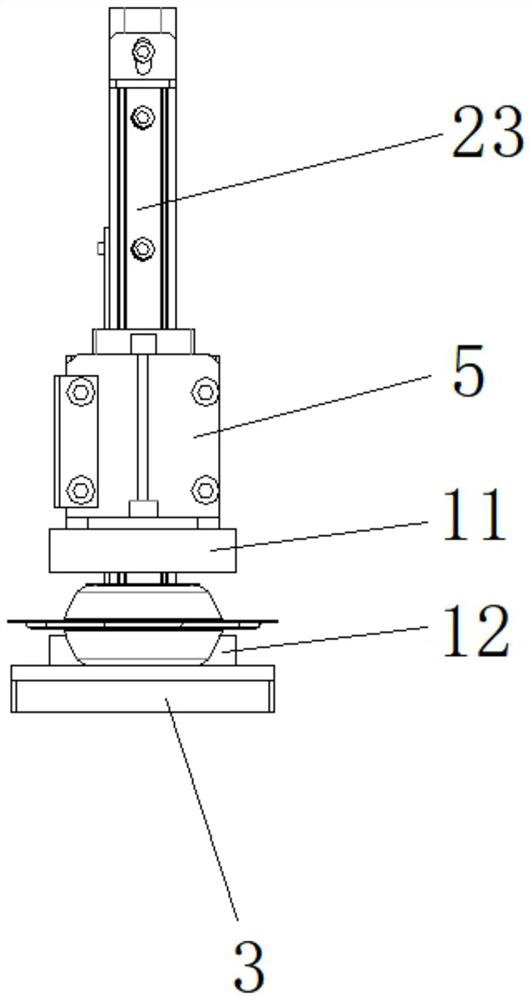

[0069] This embodiment one provides a kind of concentricity detection method, installs upper profiling block 11 and lower profiling block 12 on the concentricity detection device, upper profiling block 11 and lower profiling block 12 and the oil bag of heat sink to be measured The shape and size are the same, the oil bag of the heat sink is attached to the upper profiling block 11 and the lower profiling block 12 respectively, and the upper profiling block 11 is pressed down to obtain the standard value data of the vernier caliper 22, and then the heat sink is removed. Place the welded first heat sink assembly in the middle of the profiling mechanism 1, press down the upper profiling block 11, and obtain the first comparison value data of the vernier caliper 22, the difference between the first comparison value and the standard value is the first nominal value value. Compare the first nominal value with the set threshold, if the first nominal value is less than the set thresho...

Embodiment example 2

[0072] The second embodiment provides a concentricity detection method, on which the upper profiling block 11 and the lower profiling block 12 are installed on the concentricity detection device, and the upper profiling block 11 and the lower profiling block 12 are connected with the oil bag of the cooling fin to be measured. The shape and size are the same, the oil bag of the heat sink is attached to the upper profiling block 11 and the lower profiling block 12 respectively, and the upper profiling block 11 is pressed down to obtain the standard value data of the vernier caliper 22, and then the heat sink is removed. Place the welded first heat sink assembly in the middle of the profiling mechanism 1, press down the upper profiling block 11, and obtain the first comparison value data of the vernier caliper 22, the difference between the first comparison value and the standard value is the first nominal value value. Comparing the first nominal value with the set threshold valu...

Embodiment example 3

[0075] The present embodiment three provides a kind of concentricity detection method, installs upper profiling block 11 and lower profiling block 12 on the concentricity detection device, upper profiling block 11 and lower profiling block 12 and the oil bag of heat sink to be measured The shape and size are the same, the oil bag of the heat sink is attached to the upper profiling block 11 and the lower profiling block 12 respectively, and the upper profiling block 11 is pressed down to obtain the standard value data of the vernier caliper 22, and then the heat sink is removed. Place the welded first heat sink assembly in the middle of the profiling mechanism 1, press down the upper profiling block 11, and obtain the first comparison value data of the vernier caliper 22, the difference between the first comparison value and the standard value is the first nominal value value. Compare the first nominal value with the set threshold, if the first nominal value is less than the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com