Intelligent equipment motor end cover spigot surface milling lathe and operation method

A technology of motor end caps and spigots, which is applied in the field of intelligent equipment motor end cap spigot face milling lathes, can solve the problems of difficult operation, low clamping efficiency, poor fixing effect, etc., so as to avoid damage and reduce The effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

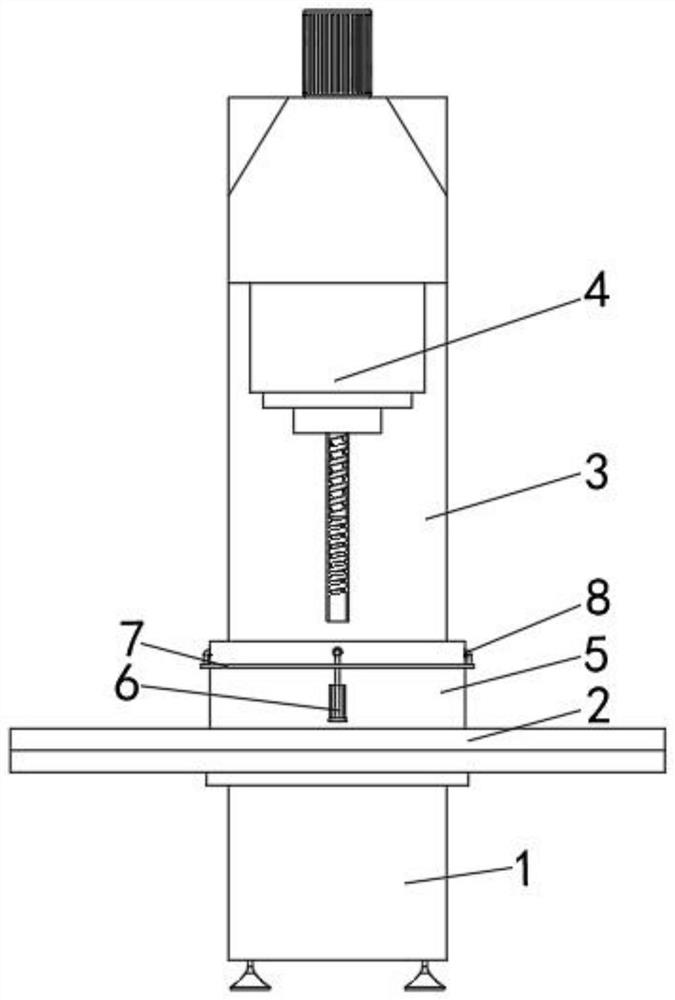

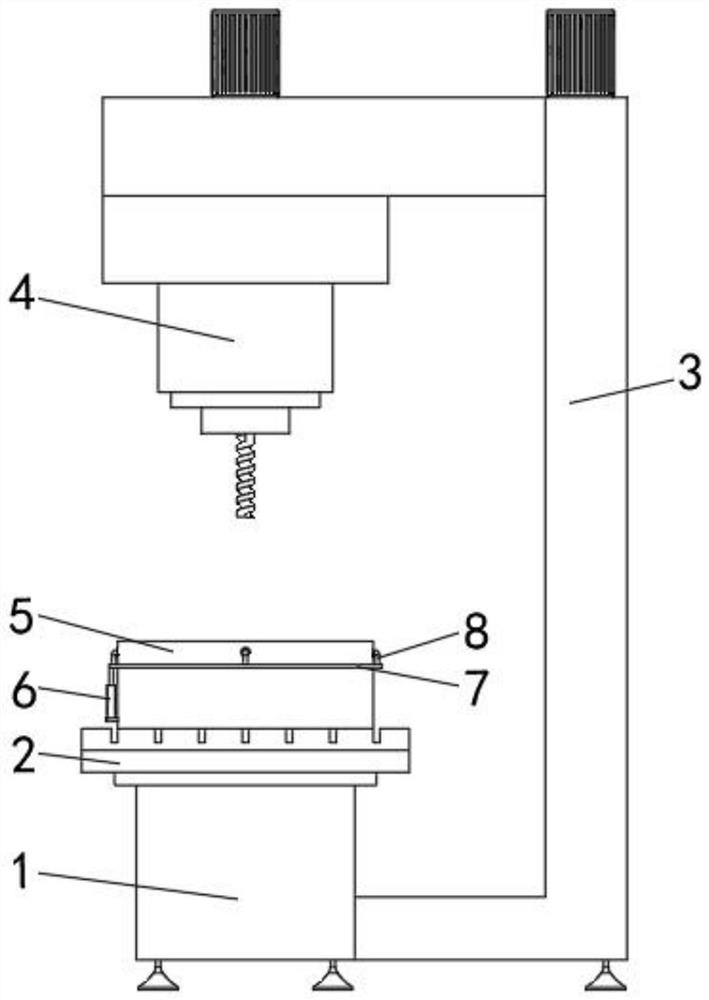

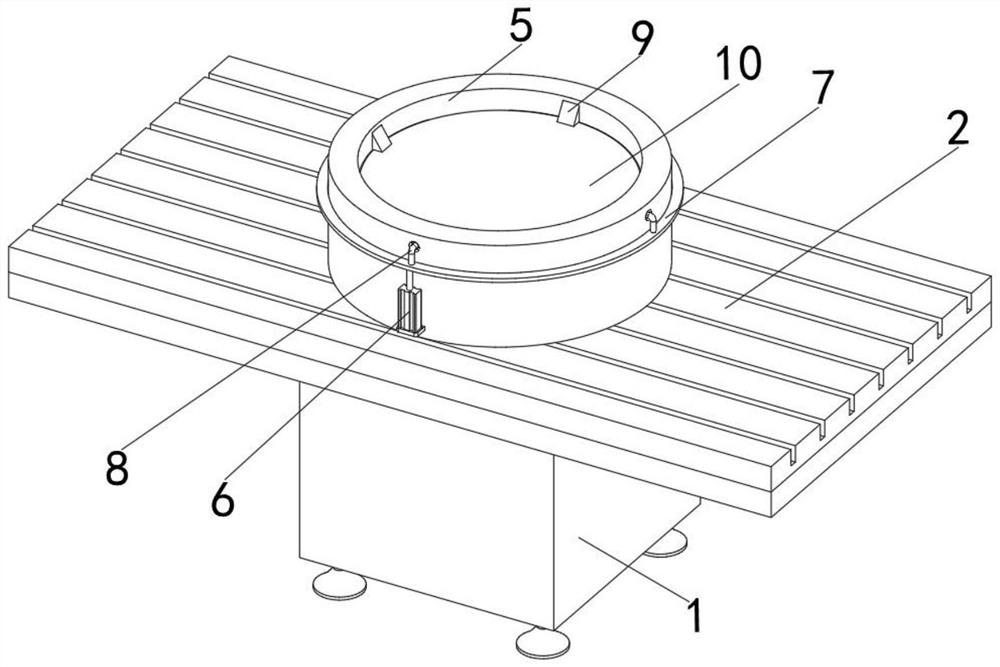

[0048] see Figure 1-9 , the present invention provides a technical solution: an intelligent equipment motor end cover seam face milling lathe, including a workbench 1 and a processing component 3, a moving seat 2 is movably installed on the top of the workbench 1, and the top of the processing component 3 The main shaft 4 is fixedly installed, the bottom of the main shaft 4 is movably equipped with a tool, the top of the moving seat 2 is fixedly installed with a fixed fixture 5, and the inner surface of the fixed fixture 5 is provided with a limit groove 16 and a sealing groove 14 distributed up and down. The inside of 16 is provided with a limit mechanism, the limit mechanism includes a limit block 9 and a transmission rope 8, the outer edge of the bottom of the fixed fixture 5 cavity is provided with a No. 1 liquid storage tank 52, and the bottom of the fixed fixture 5 cavity is provided with a placement groove 51 , the opening at the top of the No. 1 liquid storage tank 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com