Cutter tensioning and loosening device based on cam-ratchet mechanism

A ratchet mechanism and cam technology, applied in positioning devices, manufacturing tools, metal processing mechanical parts, etc., can solve problems such as bearing failure, unbalanced movement of the fork position, and reduced spindle running quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

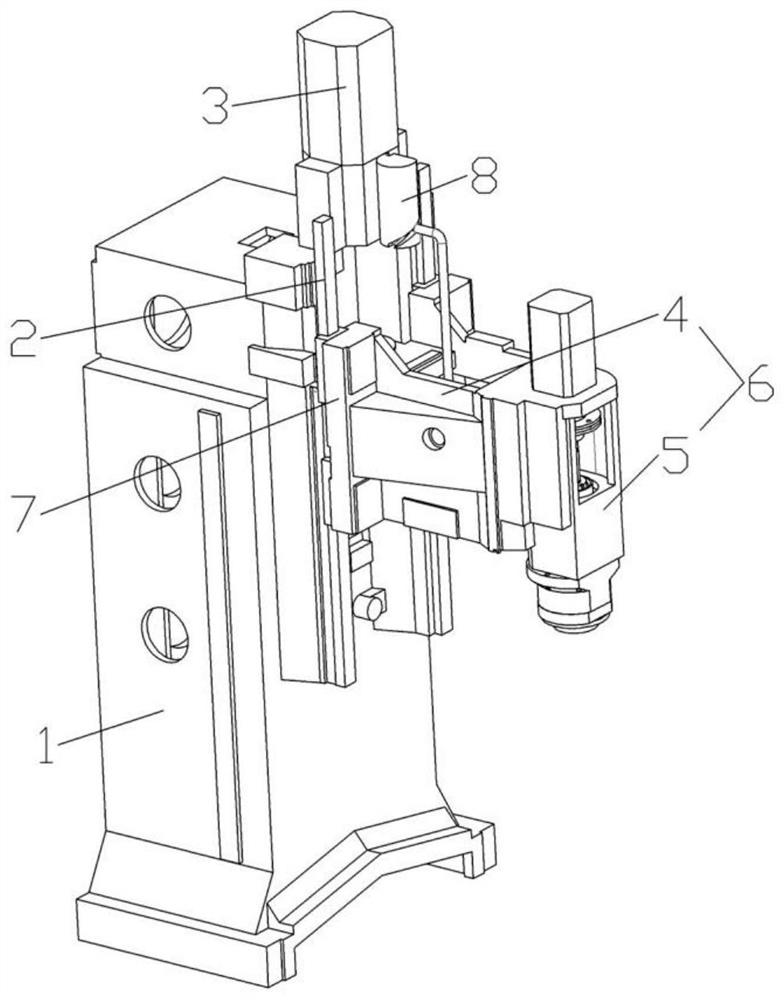

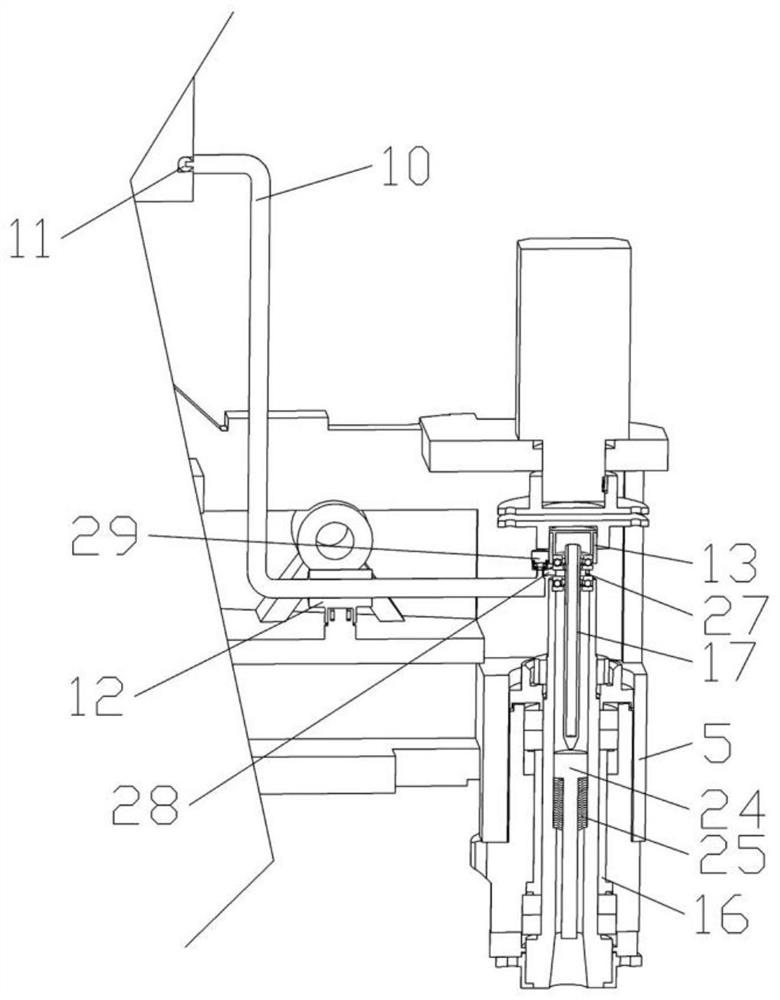

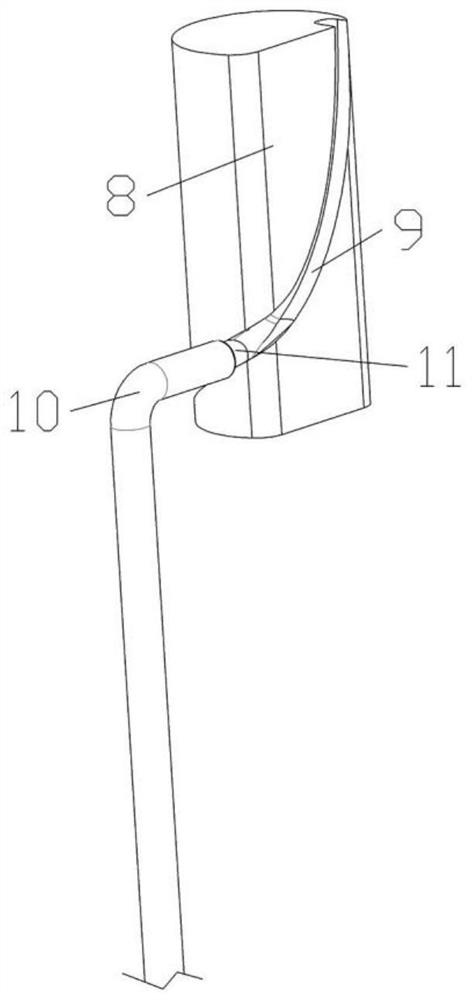

[0024] The specific embodiment of the tool tightening and loosening device based on the cam-ratchet mechanism of the present invention, such as Figure 1 to Figure 5 As shown, it includes a column 1 on which there are two slide rails 2 extending vertically and arranged in parallel and spaced apart. A screw rod is installed at a position between the two slide rails 2 of the column 1, and the axis of the screw rod extends vertically. The upper end and the lower end of the screw are respectively installed on the column 1 through bearing rotation, the upper end of the screw protrudes to the upper side of the bearing, the drive motor 3 is fixedly installed on the column 1, and the output shaft of the drive motor 3 is fixed to the upper end of the screw through a coupling connect. After the drive motor 3 starts, the drive screw rotates.

[0025] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com