Steel pipe port polishing device

A port and steel pipe technology, applied in the field of steel pipe port grinding devices, can solve the problems of burrs, uneven end surfaces, low grinding efficiency, etc., and achieve the effect of adjustable grinding angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object and advantages of the present invention more clearly understood, the following embodiments of the present invention in conjunction with the embodiments will be specifically described, the following detailed description of the specific features of a steel pipe port grinding device:

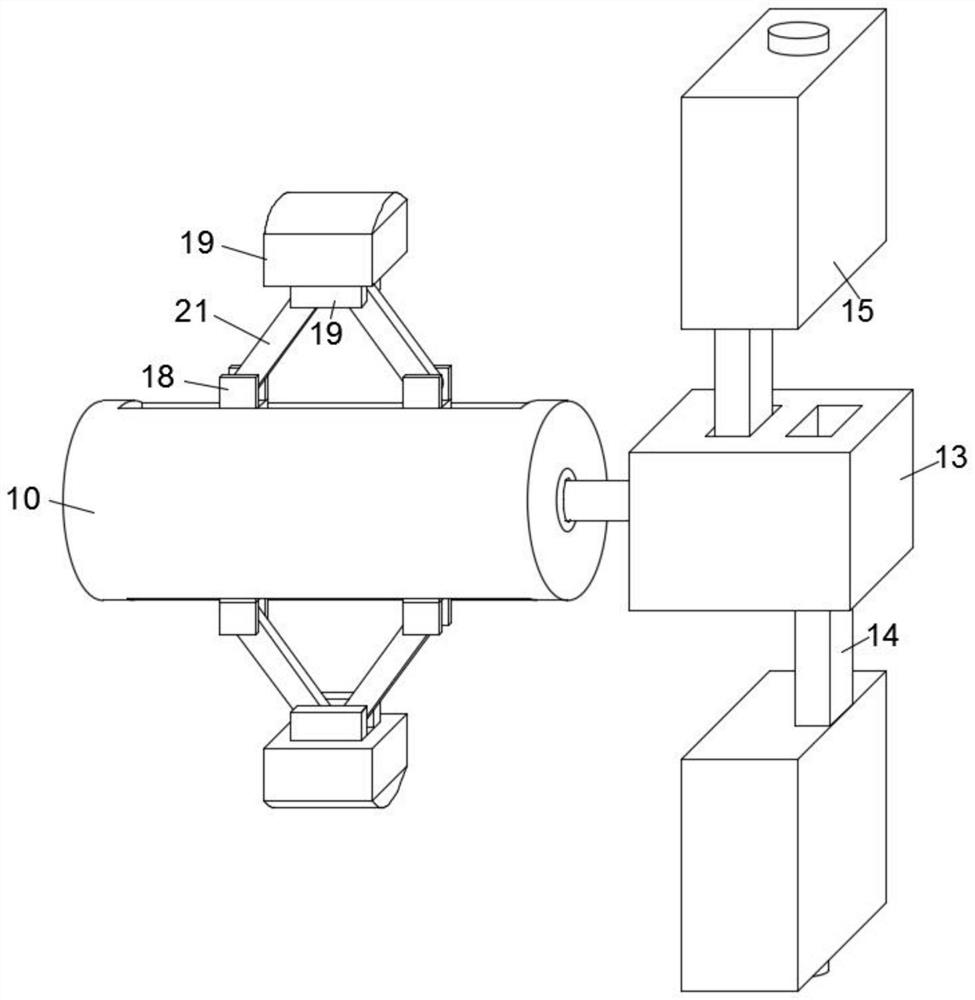

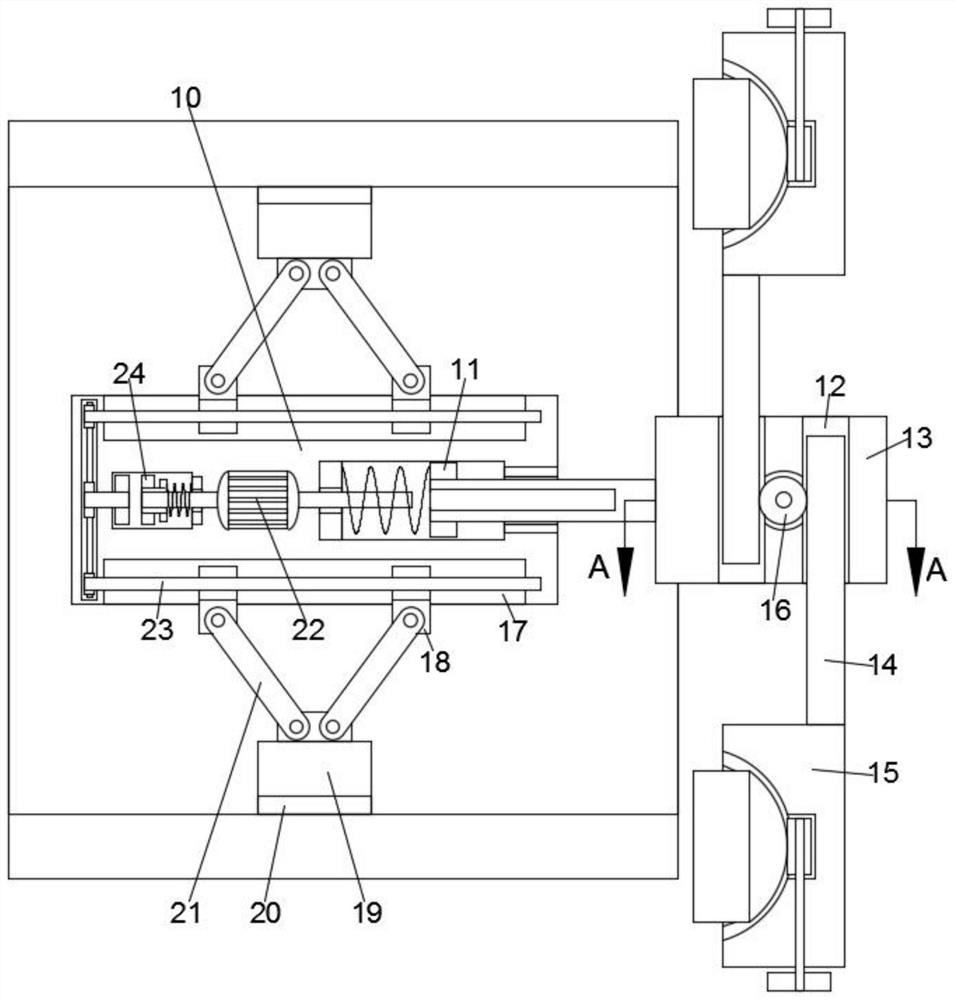

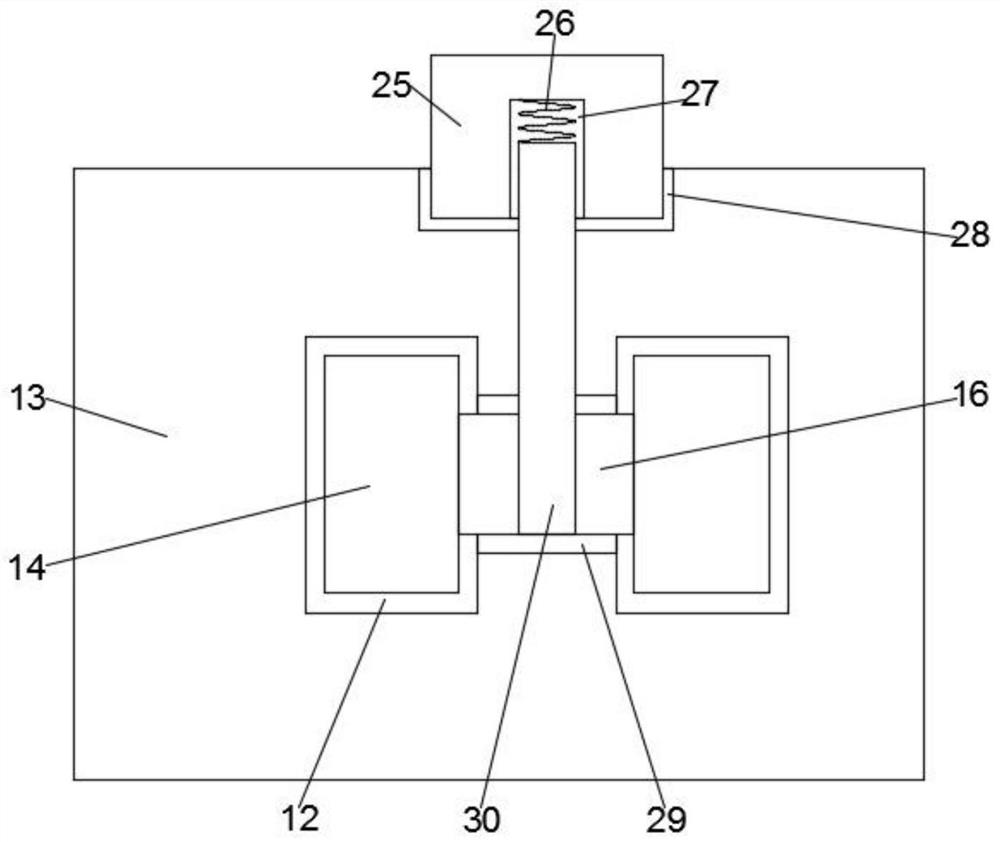

[0024] Reference Figure 1- Figure 7 , according to an embodiment of the present invention, a steel pipe port grinding device, comprising the main box 10, the main box 10 is provided with a supporting component for supporting the inner wall of the steel pipe, the main box 10 is provided with a grinding component for grinding the steel pipe port;

[0025] The supporting assembly comprises two support blocks 19 arranged symmetrically up and down, two support blocks 19 are fixed to the outer end face of the friction block 20, two support blocks 19 near the main box 10 side end face are articulated with two left and right symmetrical connecting rods 21, four connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com