Operating table for maintenance of explosive ordnance disposal robot

An EOD robot and operating table technology, which is applied in the direction of workbench, lifting device, manufacturing tools, etc., can solve the problems of inconvenient EOD robot maintenance work, heavy weight of EOD robot, and low maintenance work efficiency, so as to improve maintenance and The efficiency of assembly, the improvement of maintenance efficiency, and the effect of reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

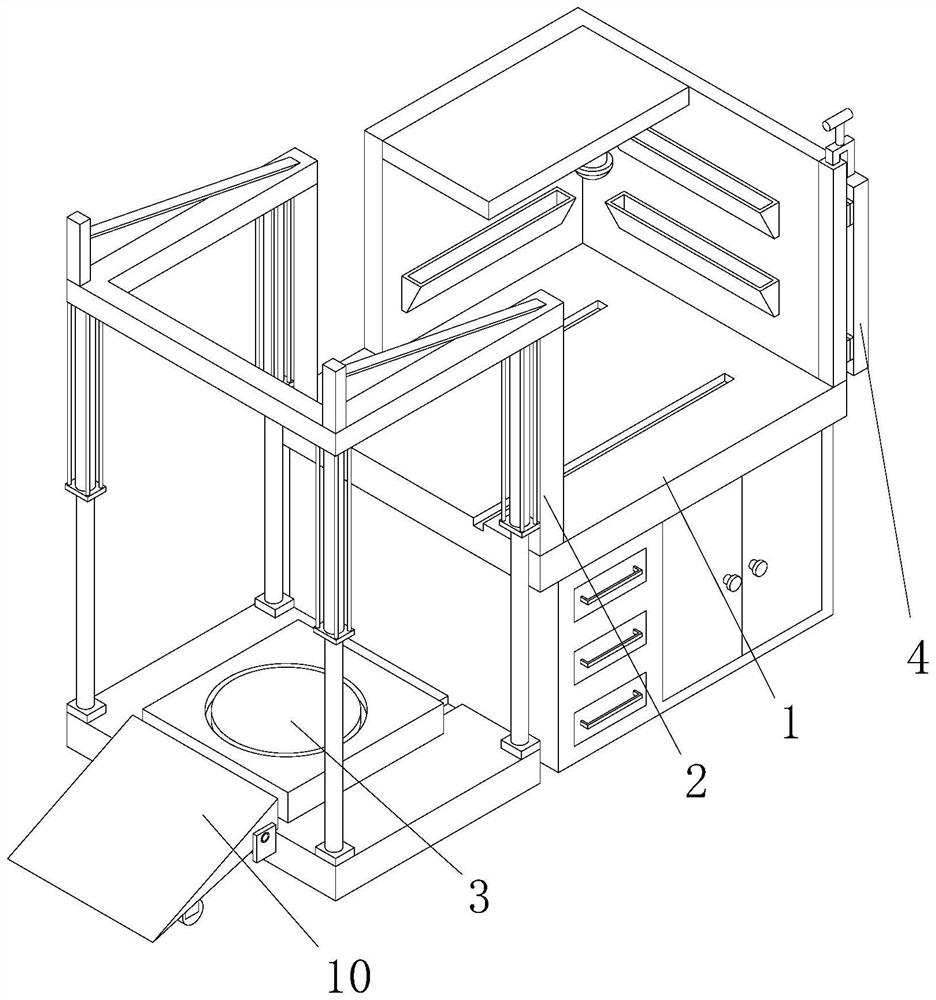

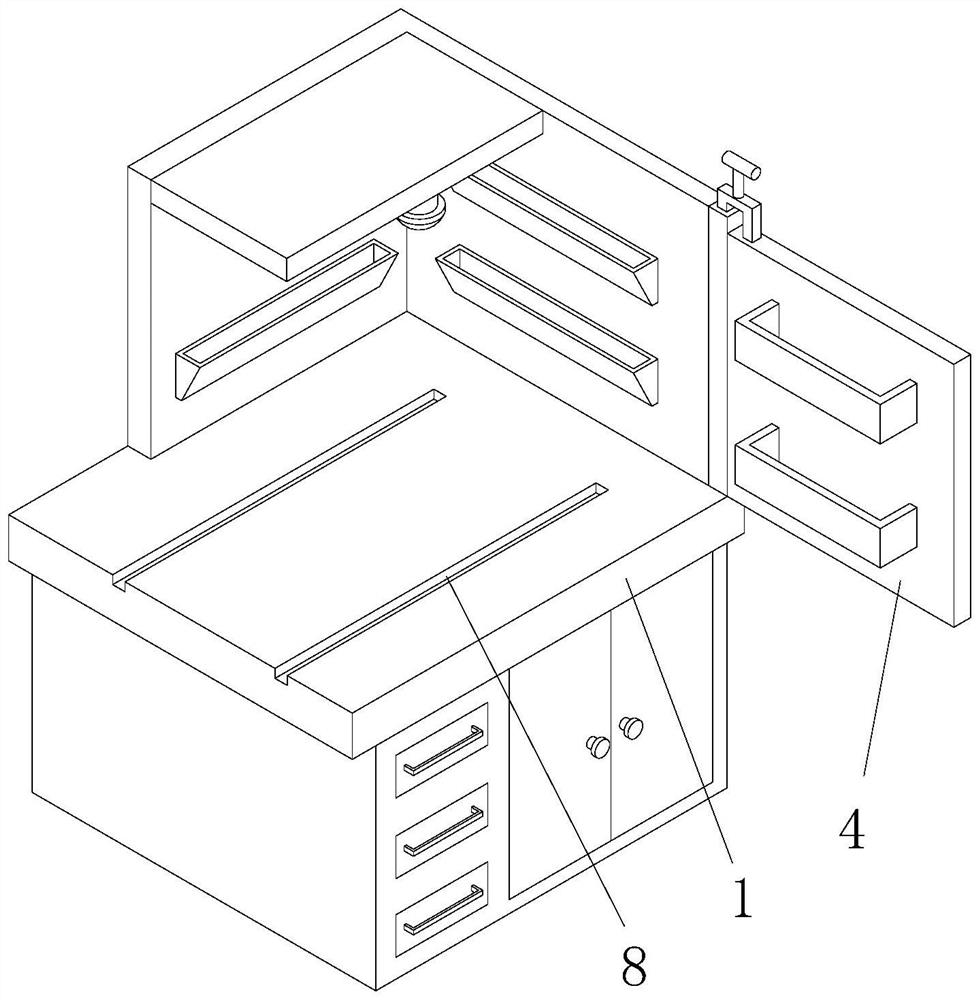

[0042] Such as Figure 1-10 As shown in the figure, an operation table for maintenance of an EOD robot includes an operation table body 1;

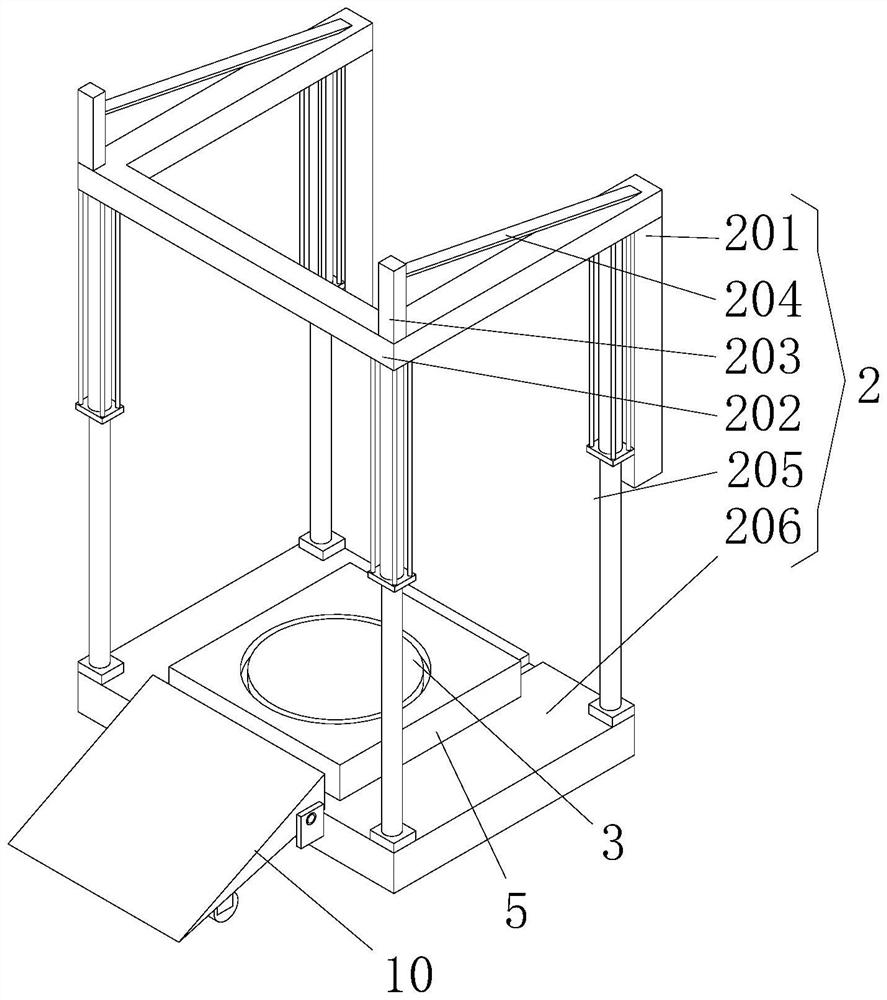

[0043] Lifting mechanism 2, the bottom of the lifting mechanism 2 is fixedly connected with the top of the console body 1, and the lifting mechanism 2 is used for the lifting work of the EOD robot;

[0044] The mobile seat 5 is movably connected to the top of the lifting mechanism 2, and the mobile seat 5 is used to move the EOD robot to the console body 1;

[0045] Rotating mechanism 3, rotating mechanism 3 is fixedly connected to the inside of moving seat 5, and rotating mechanism 3 is used to make the explosion-proof robot rotate;

[0046] A sorting mechanism 4, the side of the sorting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com