Single-cylinder injection molding machine with one-line pre-molding motor arranged in middle

A technology for injection molding machines and motors, which is applied in the field of single-cylinder injection molding machines with one-line pre-molding motors. It can solve the problems of unbalanced force of the two cylinders and easy breakage of the injection piston rod, and achieve fast force response and smooth injection process. Smooth and reliable effect with low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better illustrate and set forth the content of the present invention, the following will be expanded and described in conjunction with the accompanying drawings and implementation examples:

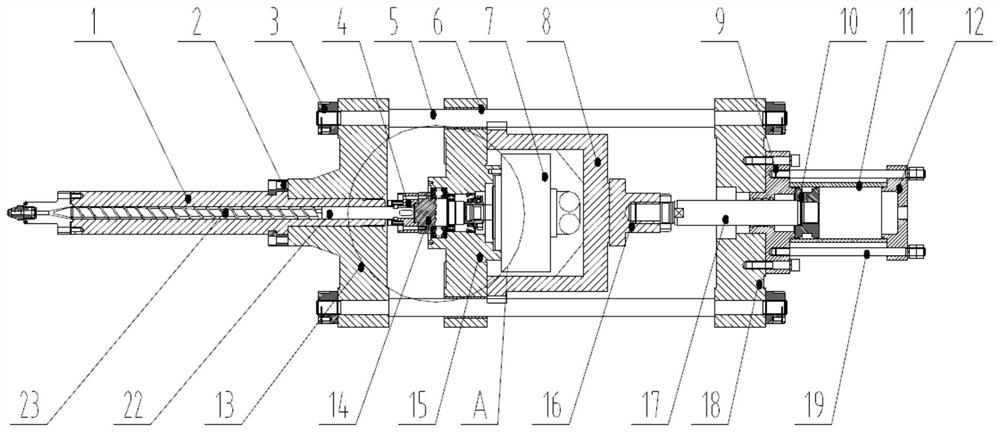

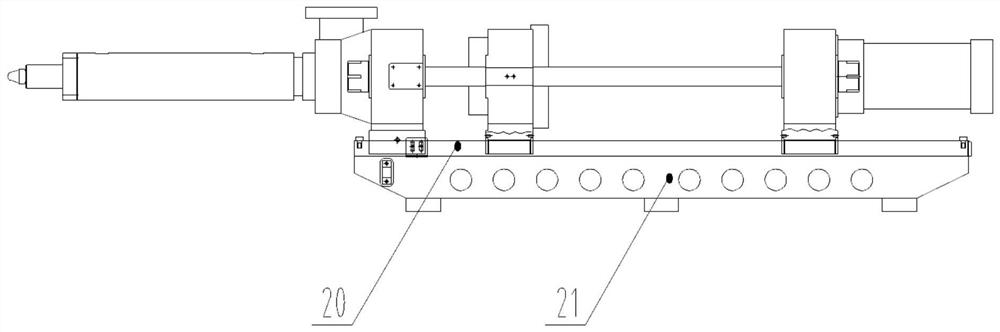

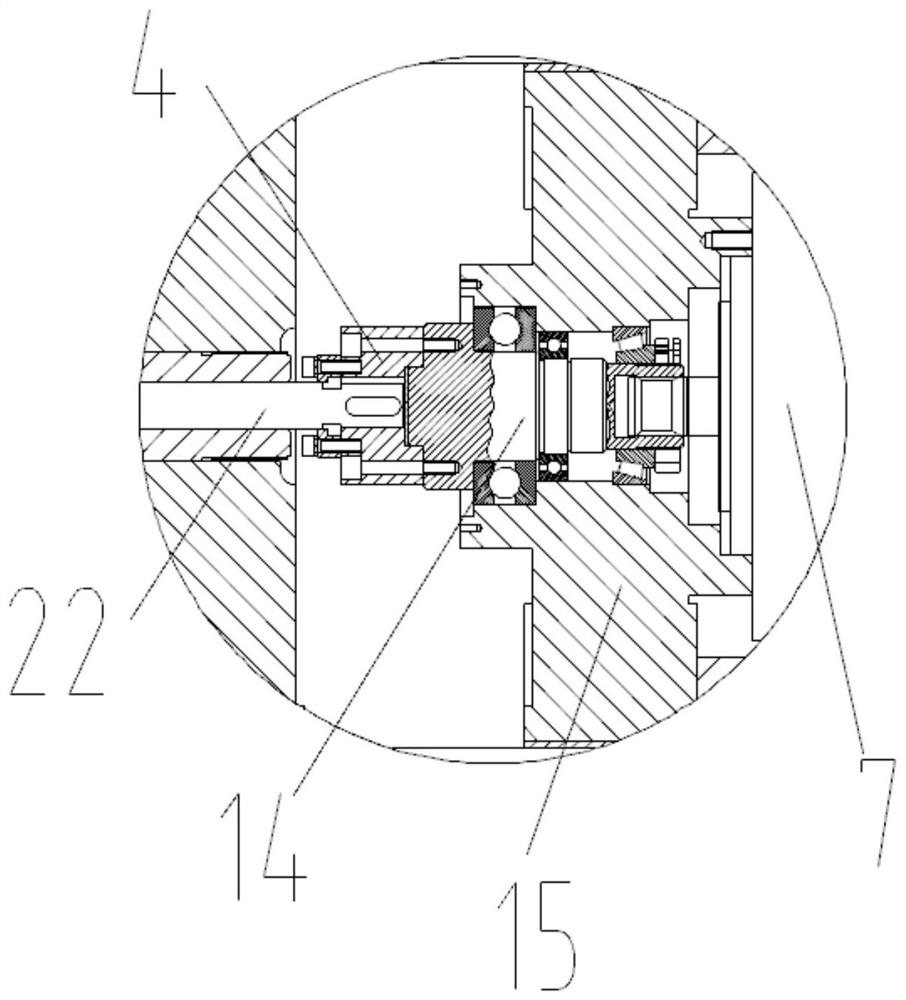

[0027] Have Figure 1-Figure 3 As shown, the present invention discloses a single-cylinder injection molding machine with a one-line premolding motor, which includes a guide rail support 21 on which an injection platform linear guide 20 is installed, and on which an injection platform linear guide 20 is installed. The front plate 13 of the shooting platform, the middle plate 15 of the shooting platform, the rear plate 18 of the shooting platform, two symmetrical pull rods 5 are installed between the front plate 13 of the shooting platform and the rear plate 18 of the shooting platform, the middle plate 15 of the shooting platform is slidably connected to the pull rods 5 and is The tie rod 5 runs through, and the left end of the front plate 13 of the injection platform i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com