Angle radar headlamp combination structure and support assembly

A technology of combined structure and bracket assembly, applied in vehicle parts, signal devices, optical signals, etc., can solve the problems of inconvenient measurement of the radar installation surface with three coordinates, the inability of the front angle radar to meet the accuracy requirements, and the flexible deformation. Avoid accuracy reduction, improve accuracy requirements, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

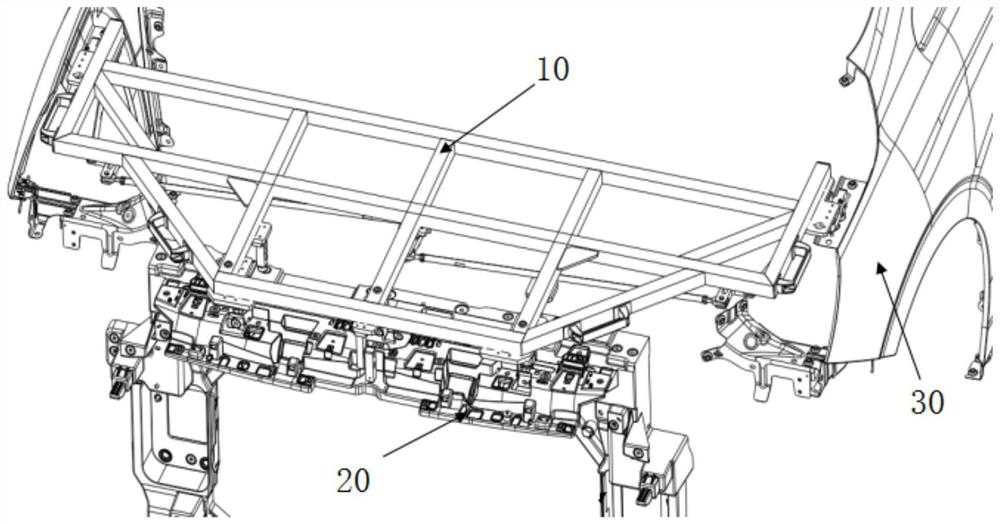

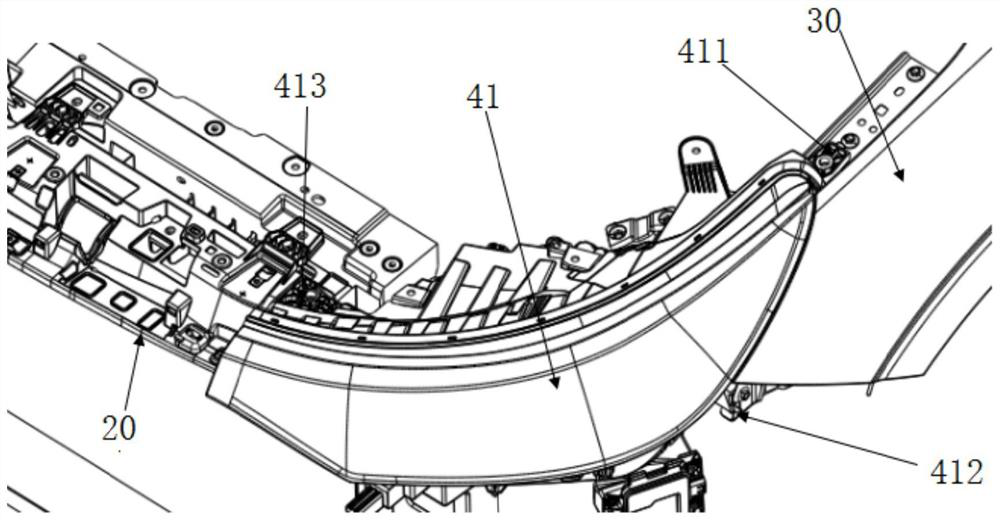

[0037] This embodiment provides a combination structure of the corner radar headlights. By arranging the relevant components of the corner radar on the headlights, it is beneficial to ensure the stability of the front foot radar installation and effectively guarantee the test of the front corner radar. precision.

[0038] In this solution, in order to improve the installation accuracy of the front angle radar, corresponding structural improvements have been made to the structure of the bracket assembly. The specific components of the bracket assembly will be introduced in detail in this solution below.

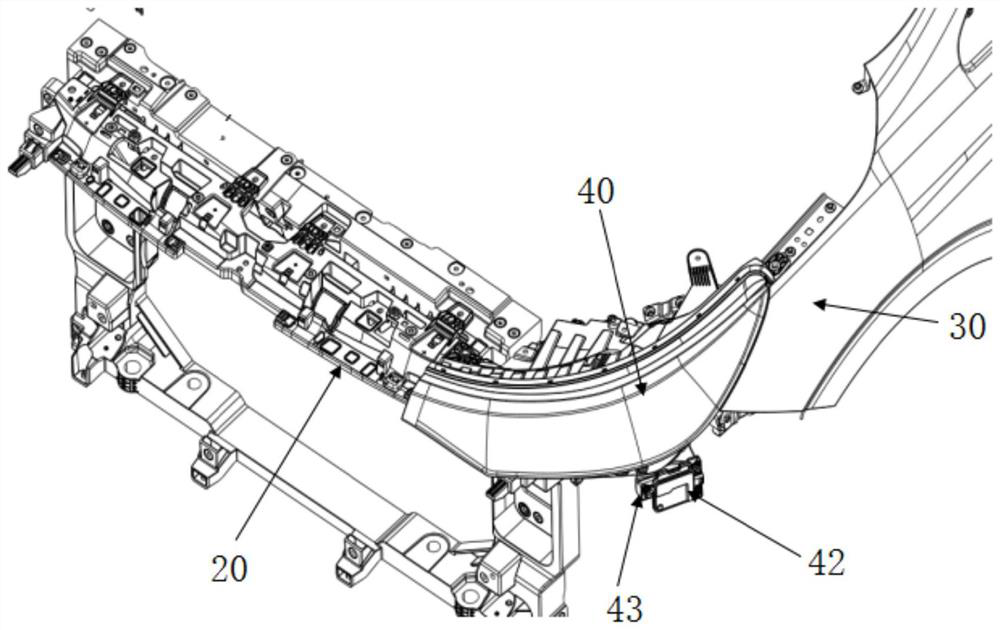

[0039] see Figure 1-Figure 8 , the bracket assembly provided in this program includes bracket tooling 10, middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com