Electrolytic bath for electrolytic aluminum and electrolytic process using electrolytic bath

An electrolytic cell and electrolytic aluminum technology, which is applied in the field of electrolytic aluminum, can solve the problems of waste gas environmental pollution, inability to efficiently absorb harmful substances in waste gas, and fine shunting of gas that cannot be discharged, so as to solve pollution, promote reaction, and absorb efficiently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

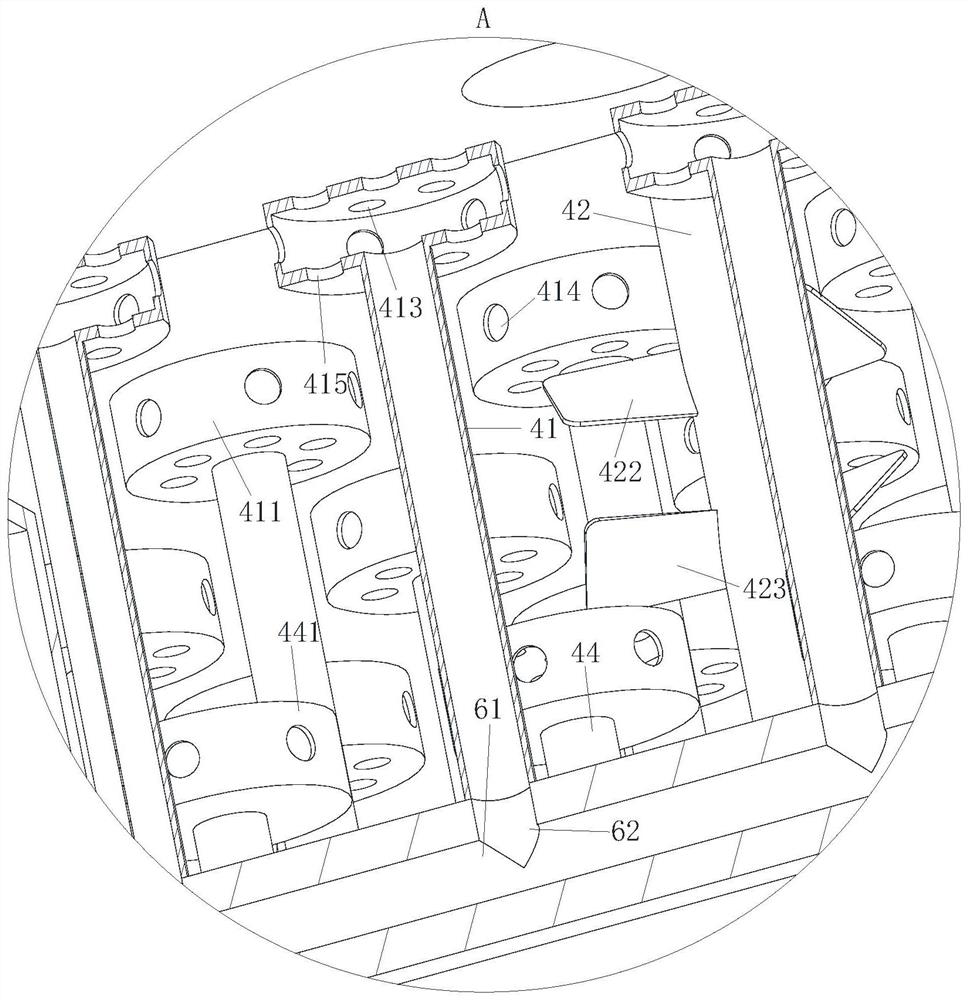

[0045] As a specific embodiment of the present invention, the lower end surface of the No. 1 nozzle 411 is uniformly provided with No. 3 nozzles 415 .

[0046] During work, the No. 1 nozzle 411 is on the upper end of the No. 2 nozzle 441, and the lower end surface of the No. 1 nozzle 411 is evenly provided with the No. 3 nozzle 415. Like this, the exhaust gas ejected from the No. 1 nozzle 413 on the No. 2 nozzle 441 The exhaust gas ejected from the No. 3 nozzle 415 will drive the strong alkaline solution to produce convection, making the mixing of the exhaust gas and the strong alkaline solution more complete, so that the reaction of CO2 gas, HF gas and strong alkaline solution is further improved. promote.

[0047] As a specific embodiment of the present invention, a stirring device 42 is uniformly arranged in the waste gas absorption box 4, and the stirring device 42 includes a stirring shaft 421, a No. 1 blade 422 and a No. 2 blade 423, and the No. 1 blade 422 and the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com