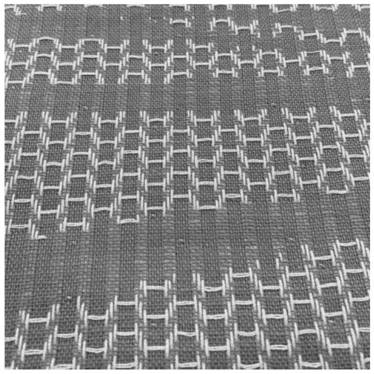

Double-layer network jacquard towel and weaving process thereof

A double-layer network and towel technology, which is applied in the direction of digging fabrics, textiles, papermaking, fabrics, etc., can solve the problem that the flat fabric surface cannot reflect the jacquard pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

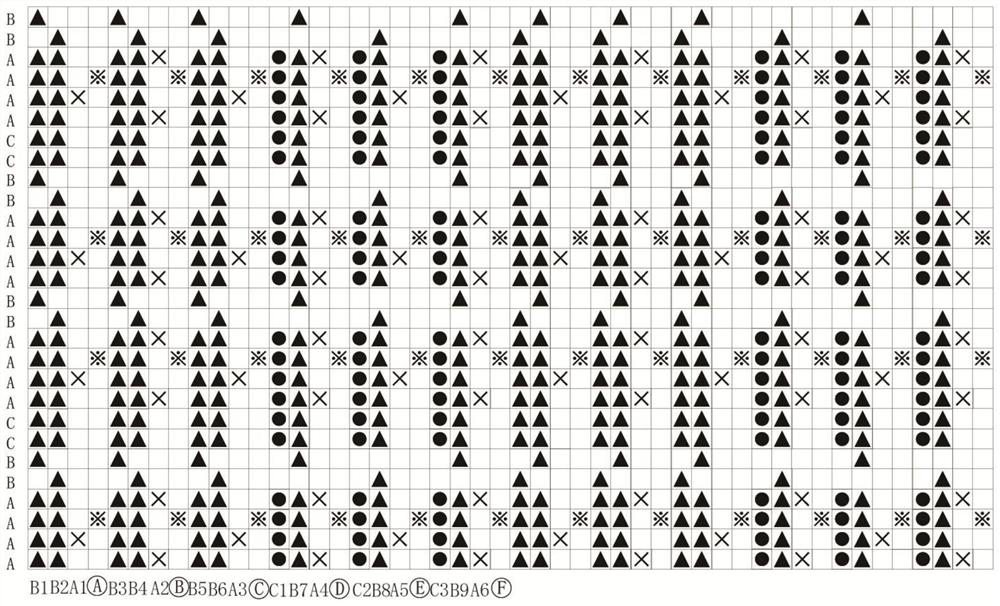

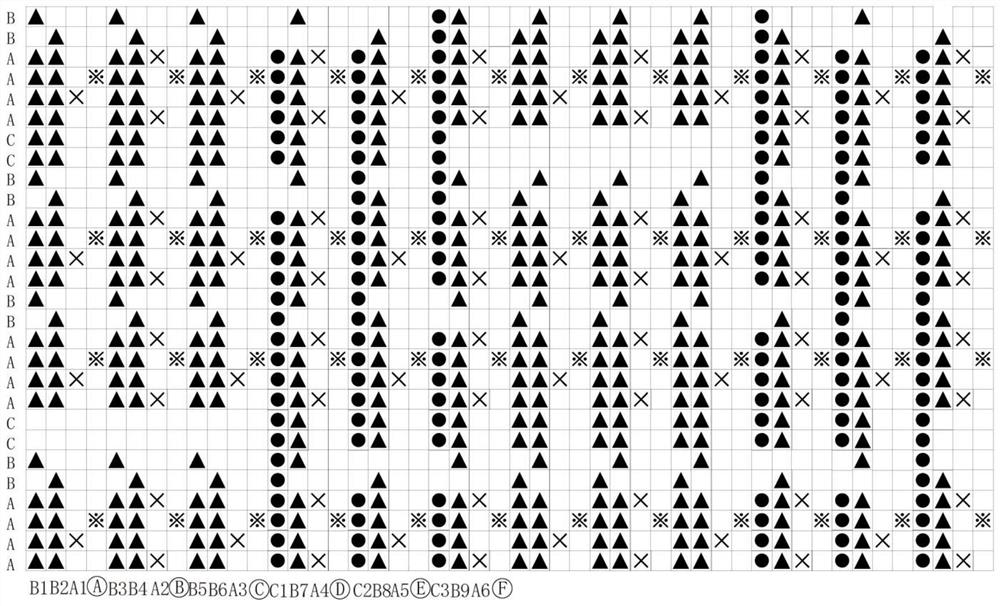

Image

Examples

Embodiment 1

[0047]Yarn selection: 32S / 2 weak twist super soft yarn is used for the wool warp yarn, and at least three colors of yarn are used for the ground warp yarn: color A, color B, and color C, A represents the raised ground warp, and B represents the plain cloth ground The warp and C represent the patterned ground warp; the wool warp is selected in color A, the patterned weft is selected in color C, the plain weft is selected in color B, and the raised weft is selected in color A.

[0048] Equipment selection: The loom needs to use towels that can obtain different tensions of the two warp yarns. Sulzer high-speed jacquard looms are selected. The ground warp tension is set at 4-5 torques, and the wool warp tension is 1-2 torques. The menopause film used in the wool warp is a light and thin menopause film ≤ 1g, which is good for fluffing. The speed of the vehicle during weaving is 360-370 rpm.

[0049] Machine weaving

[0050] The arrangement density of the ground warp is 64 threads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com