Dovetail joint concrete assembly type enclosing wall building

A dovetail tenon, prefabricated technology, applied in construction, building structure, etc., can solve the problems of difficult permanent housing construction, lack of energy saving and environmental protection, inconvenient for rapid transportation, etc. , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

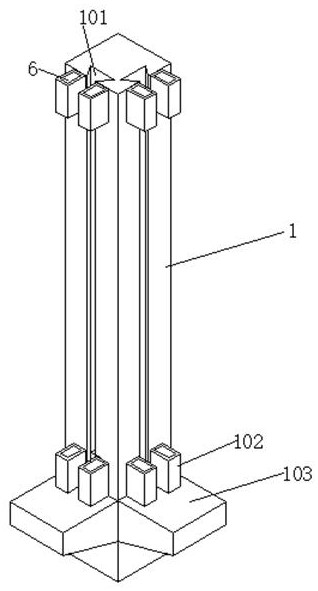

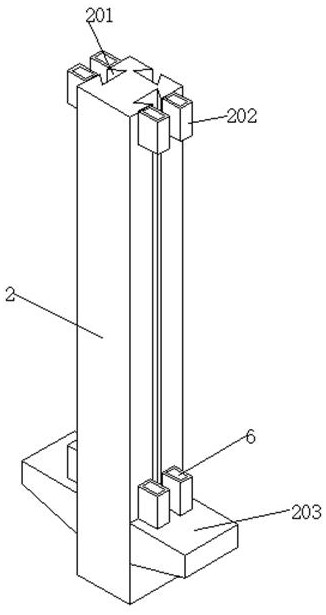

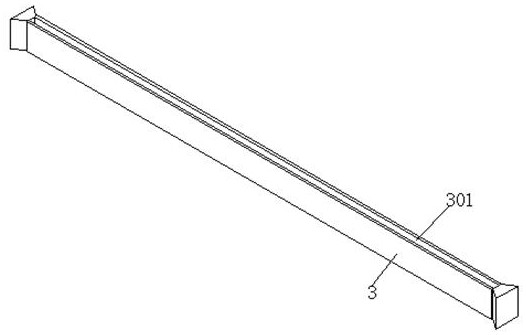

[0034] Embodiment one: if Figure 5As shown, two sets of side column dovetails 1 and a set of middle column dovetails 2 can be spliced to form a parallel wall structure. The set of two sets of side column dovetails 1 are installed on both sides, and a set of middle column dovetails 2 is placed on the At the center of the two sets of side column dovetail tenons 1, install the beam groove anchor tenon 4, the beam groove dovetail tenon 3 and the groove buckle plate 5 in order to form a parallel wall structure, and the mortise and tenon structure is convenient for assembly and transportation. It is also easy to disassemble for secondary use, greatly reducing the pollution of construction waste to the environment, and complements the national policy of carbon neutrality in the construction market.

Embodiment 2

[0035] Embodiment two: if Figure 6-8 As shown, four sets of side column dovetails 1 and two sets of middle column dovetails 2 can be spliced into a rectangular structure. The four sets of side columns dovetails 1 are installed at the four corners, and the two sets of middle column dovetails 2 are respectively placed on the two sides. At the center of the side column dovetail tenon 1, then install the beam groove anchor tenon 4, the beam groove dovetail tenon 3 and the groove gusset 5 to form a rectangular structure, which has high safety performance, fire prevention, good thermal insulation performance, and wind resistance , strong disaster resistance, long service life, and can also be used as permanent housing construction.

Embodiment 3

[0036] Embodiment three: as Figure 9-10 As shown, the middle column dovetail 2 is also provided with a structure with three sets of second grooves 201 on the top, and four sets of side column dovetails 1 and four sets of middle column dovetails 2 can be spliced into a square structure. The column dovetail 1 is installed at the four corners, and the four sets of middle column dovetail 2 are respectively placed at the center of the adjacent two groups of side column dovetail 1, and then the beam groove anchoring tenon 4, the beam groove dovetail 3 and the groove gusset are installed 5 can be spliced into a square structure.

[0037] Such as Figure 9-10 As shown, the center of the side column dovetail 1 and the middle column dovetail 2 spliced into a square structure is provided with an exhibition hall structural column 8, and the top of the exhibition hall structural column 8 is connected with a connecting piece 801, and the top four ends of the connecting piece 801 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com