Building template connecting frame for civil engineering

A construction formwork and civil engineering technology, which is applied to formwork/formwork/work frame connectors, formwork/formwork/work frame, construction, etc., can solve the problems of large load, increase the cost of column pouring, etc., and achieve improvement quality, reduce pouring construction costs, and improve convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

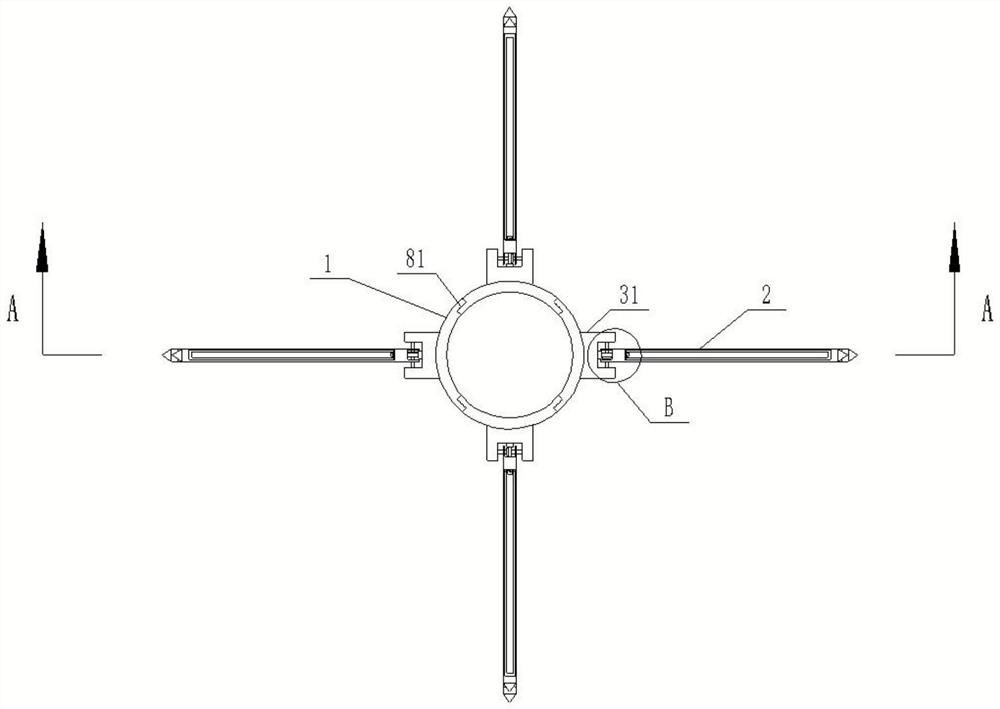

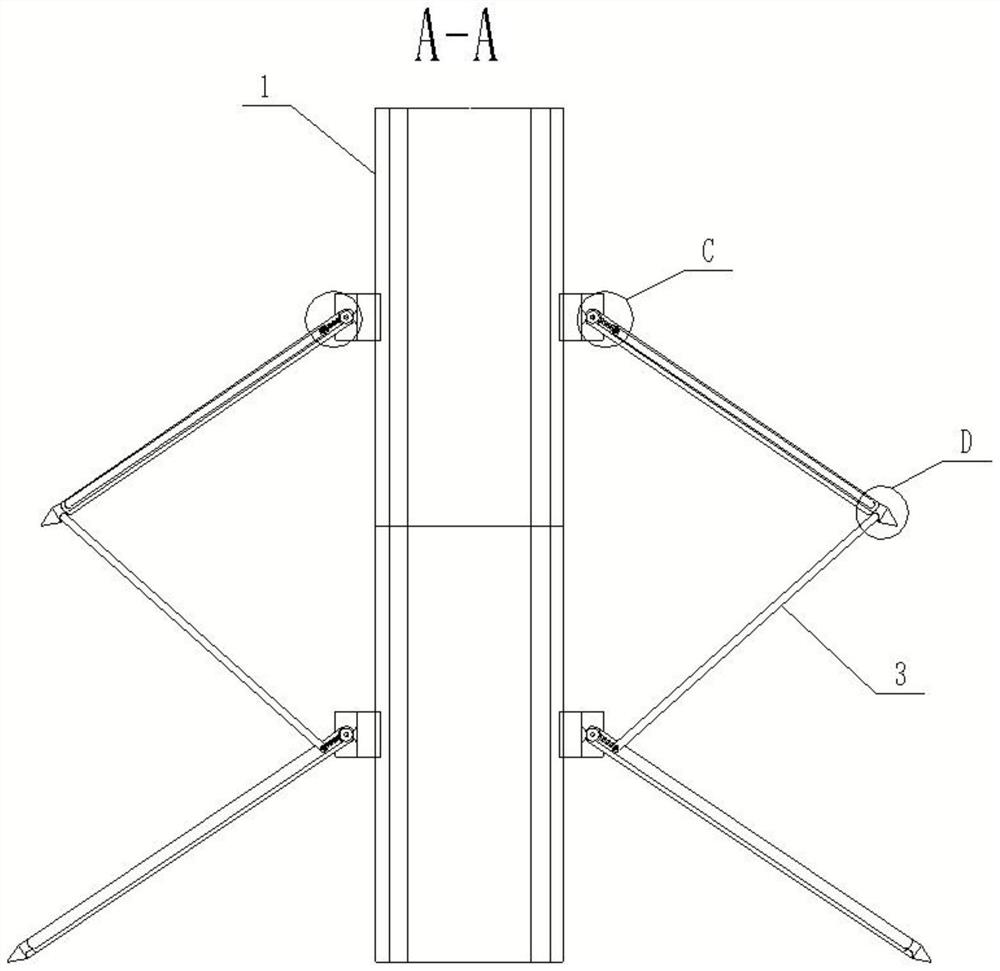

[0020] Such as figure 1 As shown, a building formwork connector for civil engineering, including: a plurality of column pouring tubes stacked sequentially from bottom to top and coaxial with each other, and adjacent tubular formworks are connected to each other to form a multi-layer column pouring formwork; The column pouring pipe includes: a plurality of arc-shaped panels 1, and the adjacent arc-shaped panels 1 are connected to each other; the support assembly is arranged on the outside of the column pouring pipe, and is used to support the column pouring pipe and Its outward load is transmitted downward; the support assembly includes: a plurality of support arms 2, which are evenly arranged on the outside of the curved panel 1, and one end of the support arm 2 is hinged to the curved panel 1; the connecting arm 3 is set On the support arm 2, one end of the connecting arm 3 is connected to the support arm 2, and the other end is connected to the support arm 2 of the upper col...

Embodiment 2

[0022] In order to further improve the pouring efficiency of the column, the installation groove of the adjustment mechanism is used in conjunction with the connecting arm to facilitate the storage and angle adjustment of the connecting arm, so that the curved panels of different height specifications can be flexibly selected for construction during column construction. At the same time, it is used in conjunction with the groove at the bottom of the support arm, which facilitates the installation of the support arms and connecting arms of the upper and lower floors, and further improves the construction convenience of column pouring.

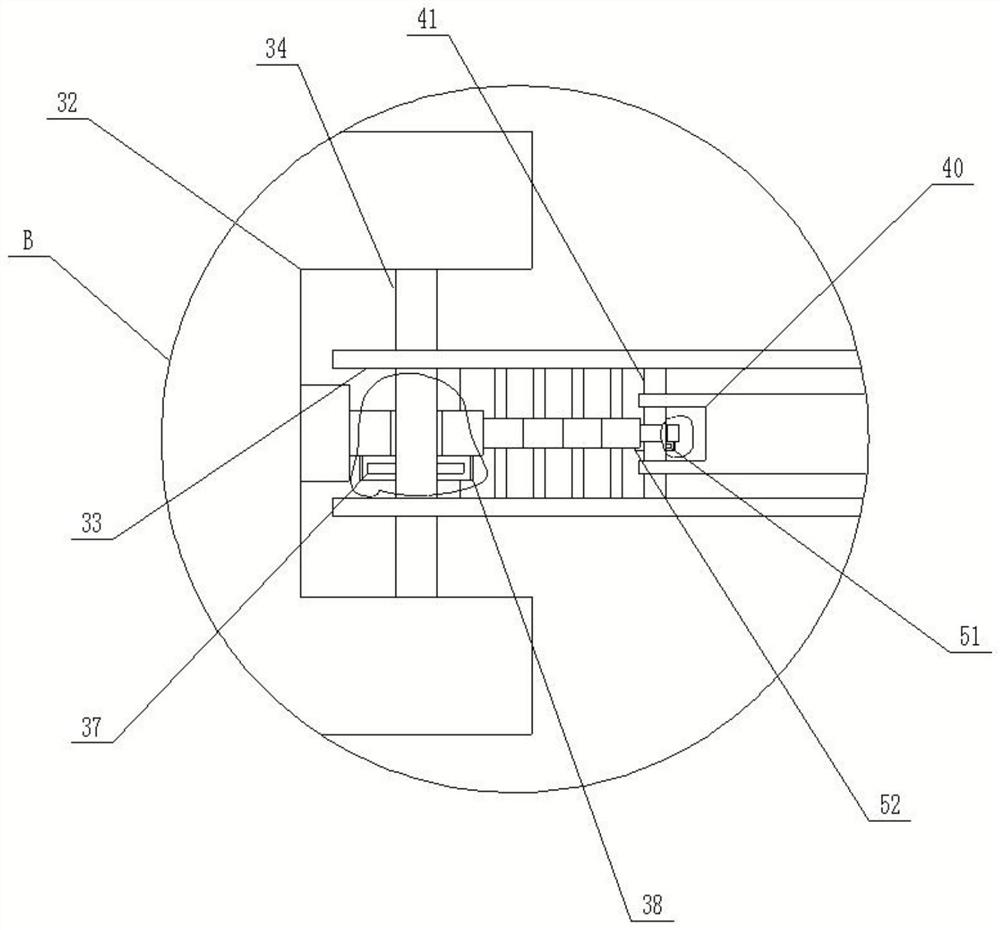

[0023] Such as figure 2 As shown, preferably, the adjustment mechanism includes a mounting groove 21 provided on the support arm 2, one end of the connecting arm 3 is embedded in the installation groove 21 near the side of the curved panel 1 and hinged to its inner wall, and the support arm 2 is away from the The bottom of one end of the curved...

Embodiment 3

[0028] In order to further improve the construction stability, the hexagonal prism is used in conjunction with the third shaft to adjust the angle of the connecting arm and the support arm according to the height specifications of the upper and lower building formwork and then lock it to avoid shaking during construction.

[0029] Preferably, the third gear 44 is pierced with a third rotating shaft 51 and is fixedly connected to it. The two ends of the third rotating shaft 51 are rotationally connected with the inner wall of the installation chamber 43 through bearings. The central axis of the third rotating shaft 51 and the installation chamber The inner wall of 43 is provided with a penetrating limiting hole 52, and the limiting hole 52 is provided with a hexagonal prism 53, which is connected with the third rotating shaft 51 and the support arm 2 respectively, and one end of the hexagonal prism 53 is provided with a handle 54 And fixedly connected with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com