Novel gas suspension bearing

A gas suspension and bearing technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problem of small bearing capacity and achieve the effect of large and stable suspension force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

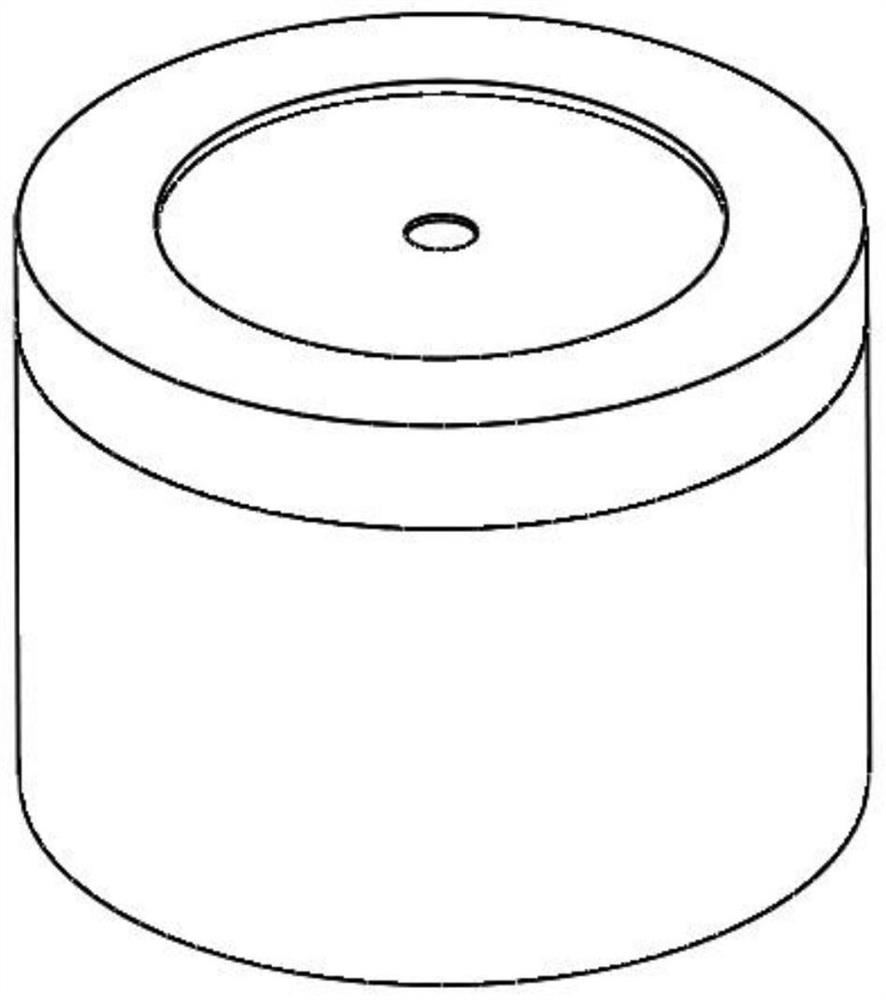

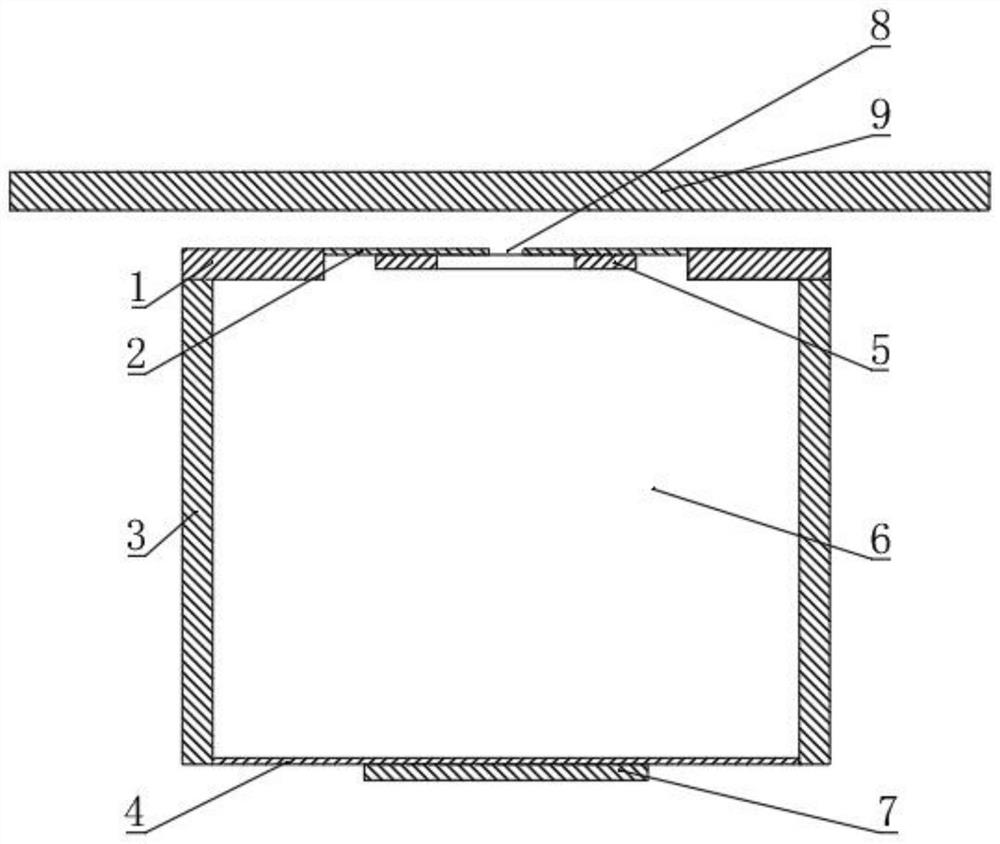

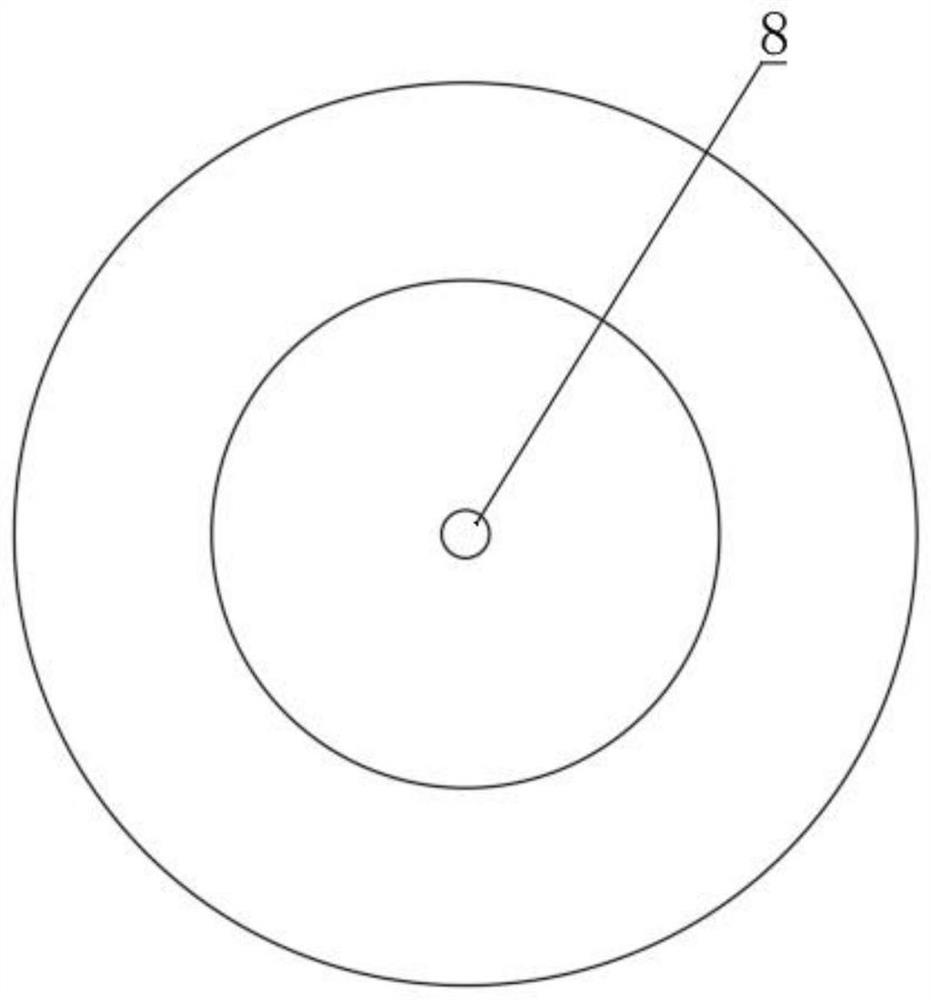

[0025] figure 1 It is the appearance diagram of Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the overall structure of Embodiment 1 of the present invention. In the present invention, by controlling the input signals of the upper and lower excitation units (5) and (7), the upper and lower metal thin films (2) and (4) generate vertical vibrations in opposite directions.

[0026] Cylinder top cover (1) is fixed during work.

[0027] When the upper metal film (2) vibrates upward, a positive force of squeezing and suspension is generated, and the volume of the cavity (3) is increased at the same time, at this time, the lower metal film (4) vibrates downward, and the volume of the cavity (3) increases , the cavity (3) inhales more gas, extrudes the positive force to compensate the suction of the synthetic jet, and produces a suspension force to carry the object (9); when the upper metal film (2) vibrates downward, a negative extrusion force is gene...

Embodiment 2

[0029] Figure 4 It is a schematic diagram of the overall structure of this embodiment. The basic structure of this embodiment is the same as that of Embodiment 1, and the upper structure remains unchanged. The difference is that the lower metal film (4) in this embodiment only serves as a seal. And the cylinder casing (3) is changed into a stacked annular piezoelectric sheet, and after the excitation signal is input, the cylinder casing (3) is made to do the vibration form of stretching up and down.

[0030] Cylinder top cover (1) is fixed during work.

[0031] The top metal film (2) still vibrates up and down. When it vibrates upwards, it produces a positive force of extruding and suspending, and at the same time increases the volume of the cavity (6). (6) Inhale more gas, squeeze the positive force to compensate the suction of the synthetic jet, and generate a suspension force to carry the object (7); when the metal film (2) vibrates downward, a negative extrusion force ...

Embodiment 3

[0033] Figure 5 It is a schematic diagram of the overall structure of this embodiment. In this embodiment, the vibration of the metal film on the upper part of the cylinder and the bottom of the cylinder is canceled, and the cylinder head (1) is enlarged. A stacked annular piezoelectric sheet is selected as the cylinder shell (3), so that the cylinder shell (3) vibrates up and down.

[0034] The cylinder bottom (5) is sealed during work.

[0035] When the whole component is working, only the cylinder wall (3) is energized to vibrate. When the cylinder wall (3) is elongated, it drives the top cylinder head (1) to squeeze air upwards, generating a positive extrusion force, and at the same time, the volume of the cavity (4) will also increase, and the cavity (4) will inhale air, generating The suction of the synthetic jet, at this time, the positive force is squeezed to compensate the synthetic jet suction of the cavity (4), and the levitation force is generated to carry the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com