Air volume reversing device for comprehensive performance test bed of air conditioning system

A comprehensive performance and air-conditioning system technology, applied in the direction of measuring devices, aerodynamic tests, vehicle tests, etc., can solve the problems of air leakage, time-consuming switching of wind direction, etc., to improve accuracy, reliable air duct connection, and reduce test consumption when the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

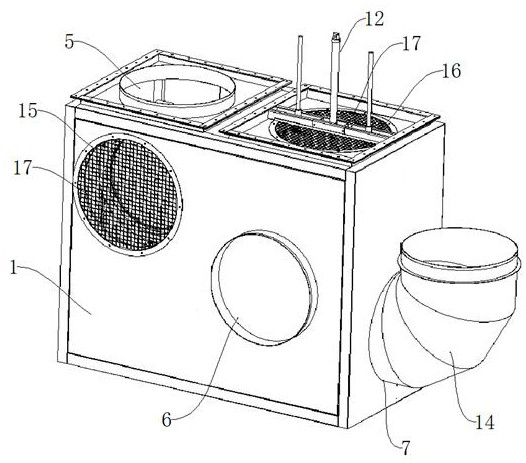

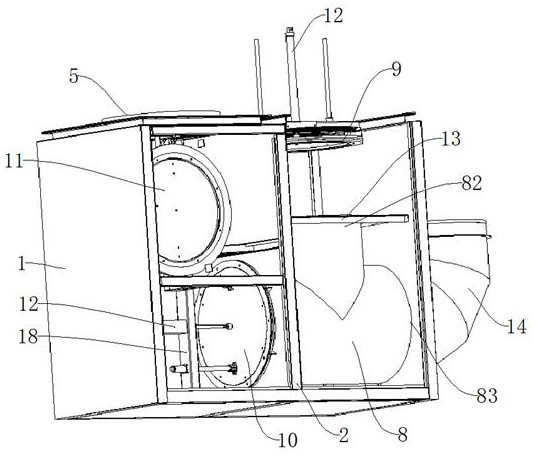

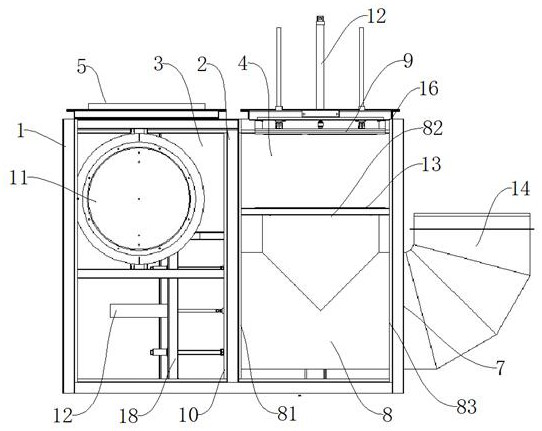

[0026] See Figure 1-Figure 3 , an air volume reversing device for an air-conditioning system comprehensive performance test bench, including a housing 1. In this embodiment, the housing 1 is in the shape of a cuboid, and a vertical partition 2 is provided inside the housing 1 to separate the housing 1. The interior is divided into two left and right chambers. The left chamber is the first chamber 3, and the right chamber is the second chamber 4. There are through holes (not shown in the figure) on the left and right of the partition plate 2. The through hole forms an air channel whose two ends communicate with the first chamber 3 and the second chamber 4 respectively. outlet end.

[0027] The housing 1 is provided with a first interface 5, a second interface 6 and a third interface 7 that communicate with the interior of the housing 1, wherein the first interface 5 communicates with the first chamber 3, and the first interface 5 is used for externally connecting the blower. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com