Thin-walled cylinder size precision analysis and AR visualization method based on point cloud

A thin-walled cylinder and dimensional accuracy technology, which is applied in image analysis, geometric CAD, image data processing, etc., can solve the problem of unintuitive display of error information, achieve the effect of solving unintuitive display, improving processing efficiency, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

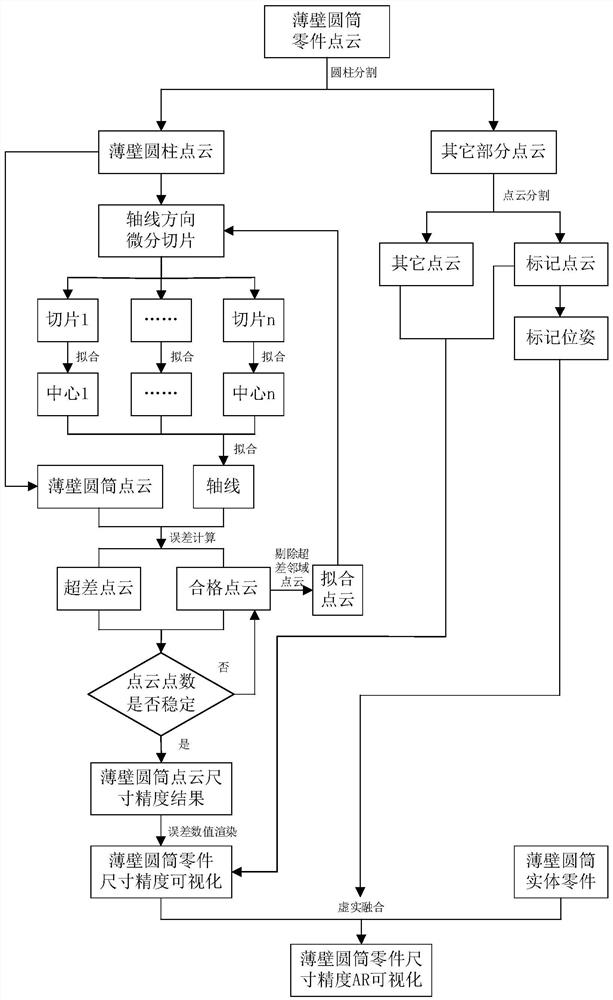

Method used

Image

Examples

specific Embodiment

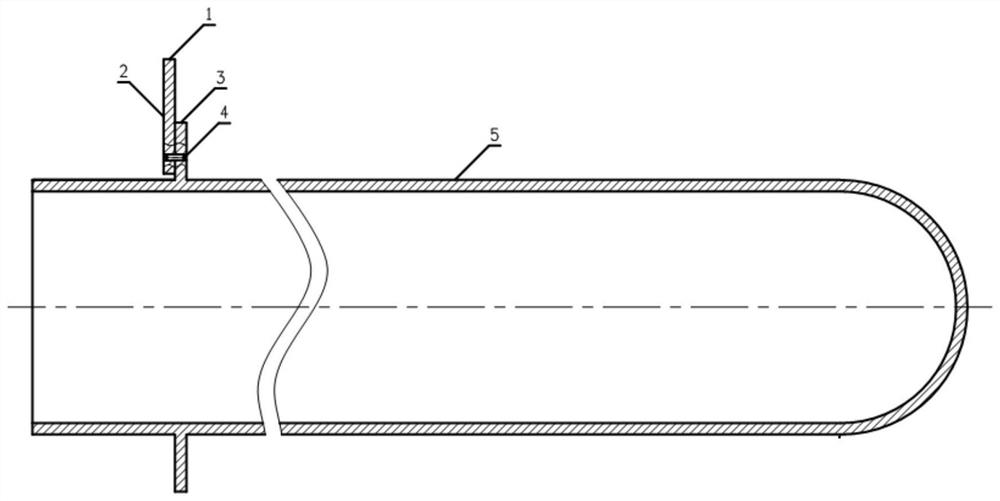

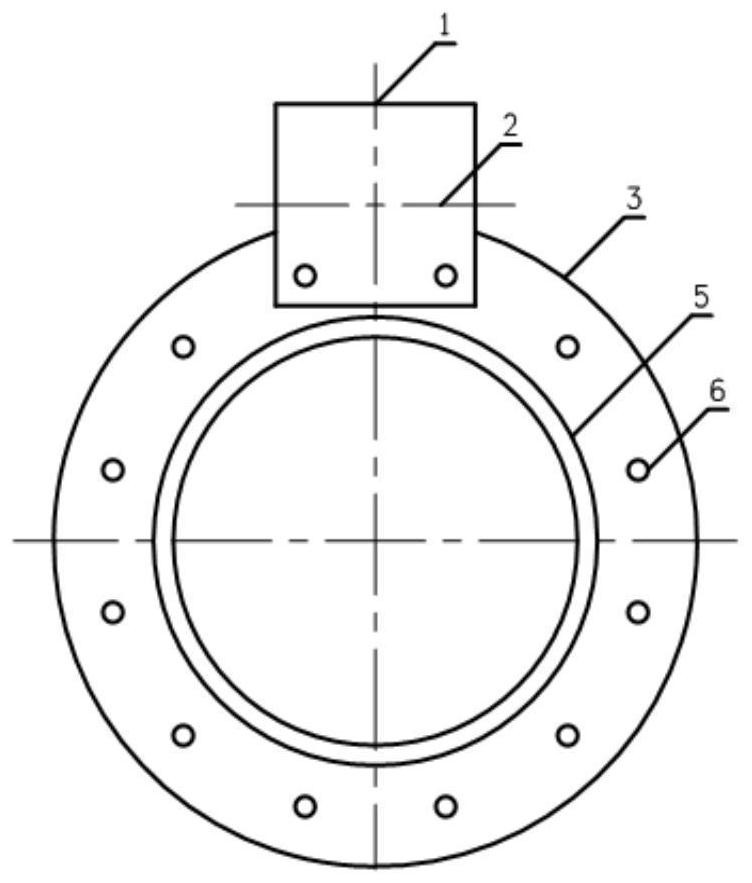

[0042] This embodiment takes the solid rocket motor housing as an example to illustrate the method in this paper, and its structural schematic diagram is as attached figure 2 , attached image 3 .

[0043] First, the cylindrical fitting method based on random sampling consistency is used to extract and segment the solid rocket motor shell point cloud, and the solid rocket motor shell point cloud can be divided into thin-walled cylinder (cylindrical) point cloud and other part of the point cloud , and get the cylinder axis equation. In order to facilitate subsequent point cloud analysis and processing, the point cloud is rotated so that the axis of the cylinder is parallel to the X axis of the space coordinate system. Then the thin-walled cylinder point cloud and other part point clouds are processed separately.

[0044] (1) Thin-walled cylinder point cloud processing:

[0045]① Differentially slice the point cloud of the thin-walled cylinder along the X-axis direction. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com