General bus grounding trolley and method for switch cabinet

A busbar grounding and switchgear technology, which is applied to the grounding device of switchgear, pull-out switchgear, switchgear, etc., can solve the problems of unreliable grounding, lack of grounding handcart, and inconvenient maintenance work, etc., to achieve grounding safety Reliable, reduce the workload of transportation inspection, and use fast and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

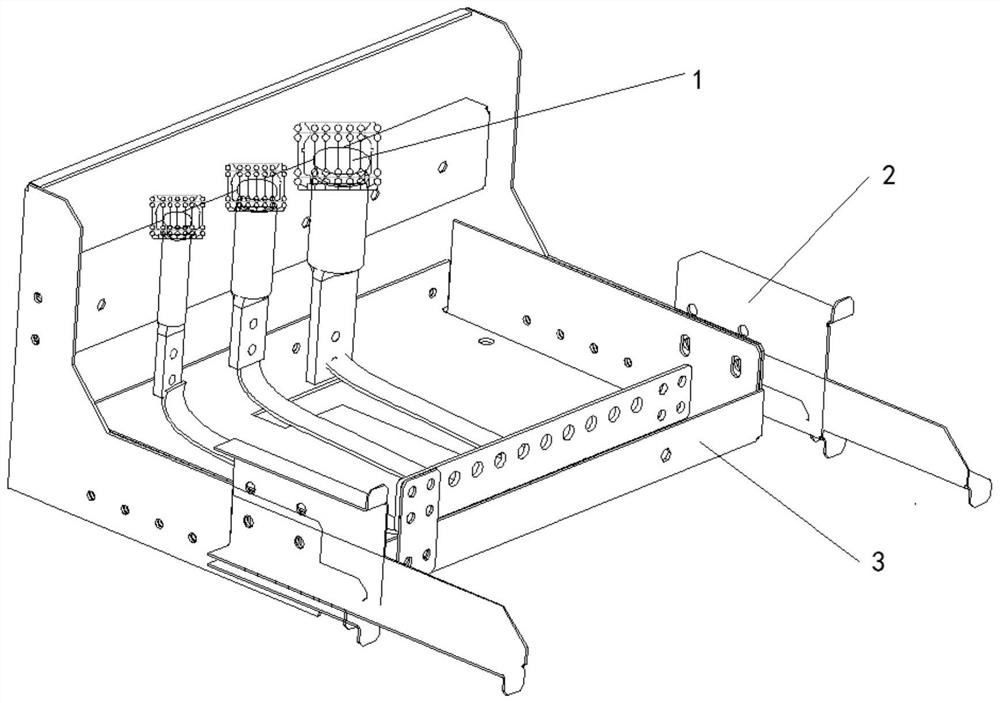

[0022] Such as figure 1 As shown, the present embodiment provides a switchgear universal busbar grounding trolley, including a car body, a valve opening device, a swing-in mechanism and a grounding device; the car body is provided with a mounting plate, and several arrays are arranged on the mounting plate The installation slots are arranged in the same way, and the installation slots are used to accommodate grounding devices of different specifications and models. The grounding devices include moving contacts, contact arms, cables and handcart grounding bars connected in sequence.

[0023] The vehicle body includes a compartment, a vehicle frame, wheels and handles. A vehicle frame is installed at the bottom of the compartment, and wheels are installed on the front and rear ends of the left and right sides of the vehicle frame. The wheels can drive the vehicle body to move, and the rear of the vehicle frame A handle is installed on the side, and the trolley can be pushed to m...

Embodiment 2

[0032] This embodiment provides a working method of a common busbar grounding trolley for a switchgear, including:

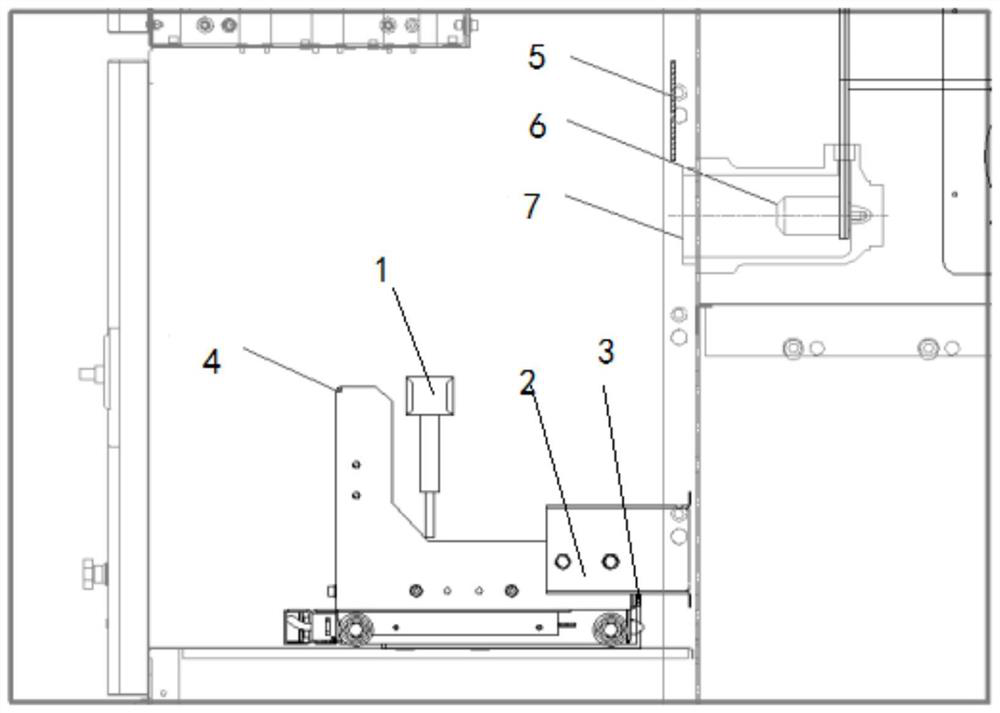

[0033] Shake the car body into the circuit breaker room of the switch cabinet through the rocking mechanism, and at the same time, the movable opening device opens the valve;

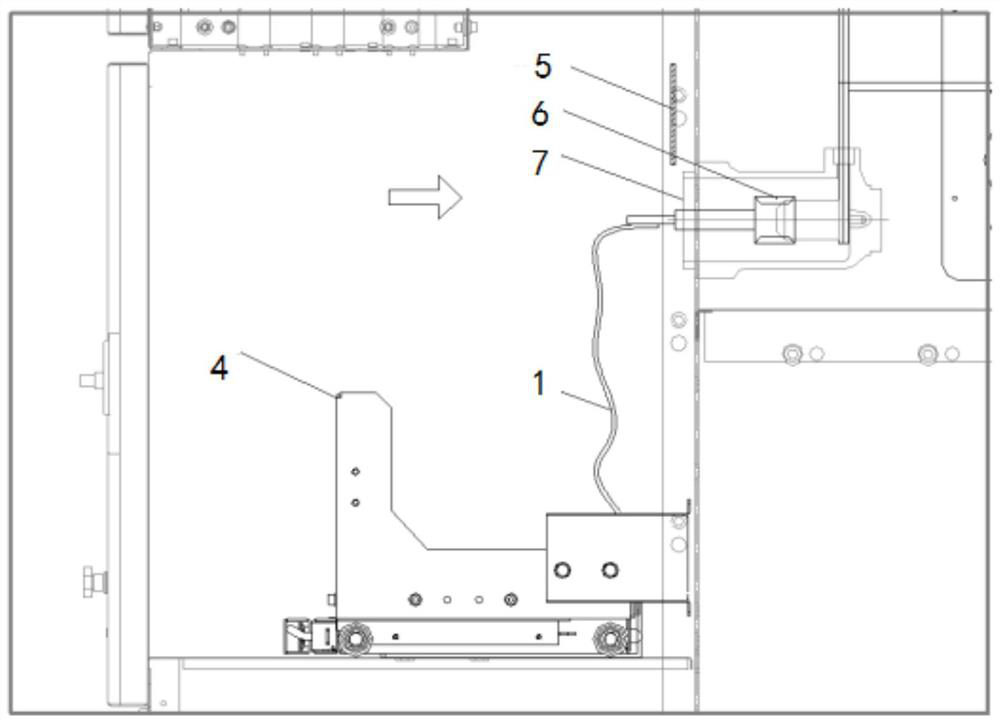

[0034] By connecting the moving contact of the grounding device to the static contact of the cabinet, the busbar is connected to the cabinet in sequence through the moving contact, cable, and grounding bar of the handcart to realize three-phase short circuit and grounding.

[0035] Specifically, during power outage maintenance, firstly, the trolley body is rocked into the circuit breaker room of the switch cabinet through the rocking mechanism, and the valve is automatically opened at the same time (see attached figure 2 ); the maintenance personnel check whether the static contacts are live through the effective electric test rod; after confirming that there is no electricity, the maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com