Stator core fixing structure of axial magnetic field motor

A stator core and axial magnetic field technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of affecting the stability of the stator core, affecting the operating performance of the motor, and poor stability of the stator core, etc. problems, achieving fast and convenient assembly, improving stability and reliability, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

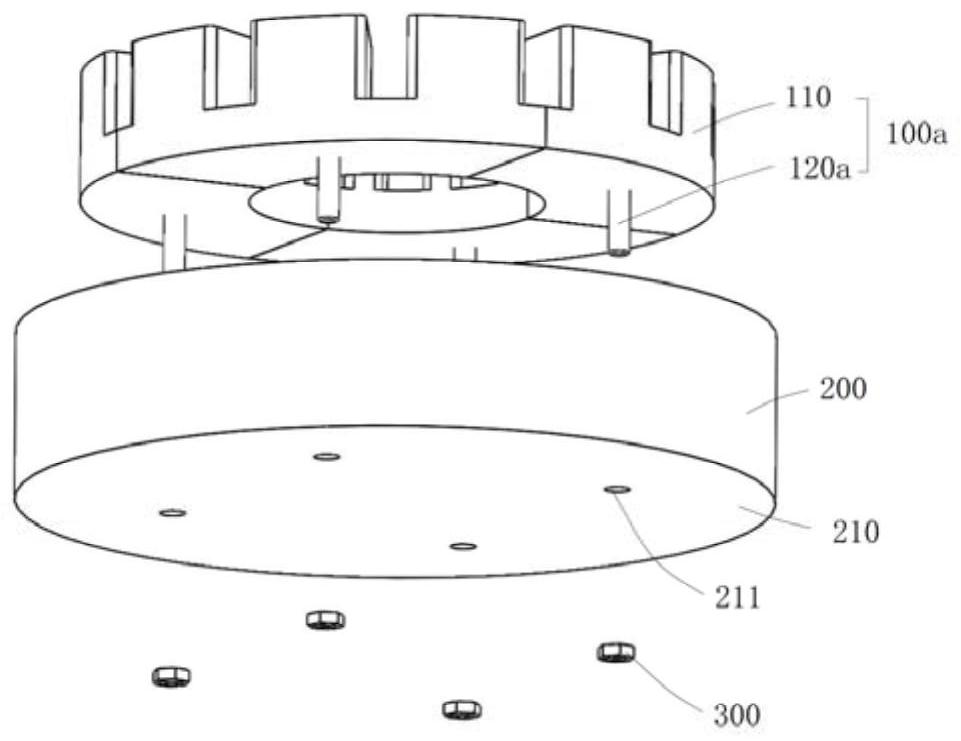

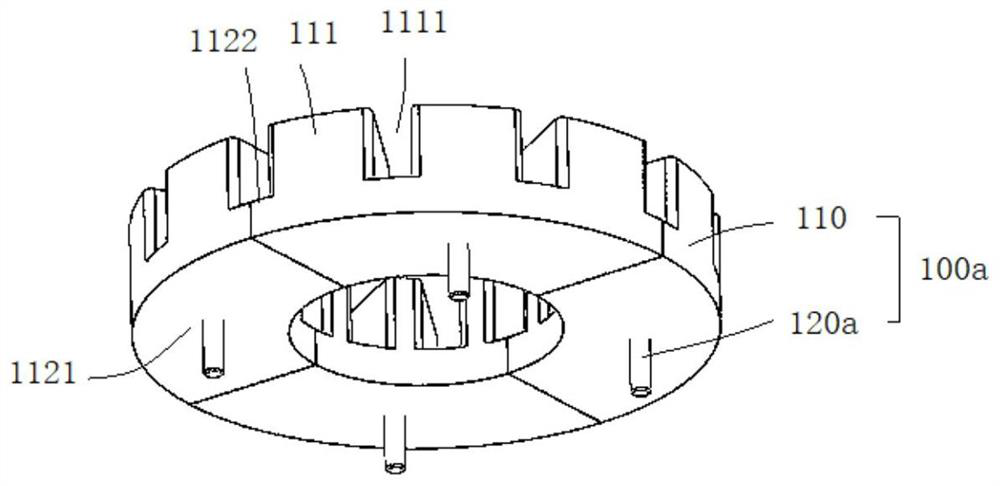

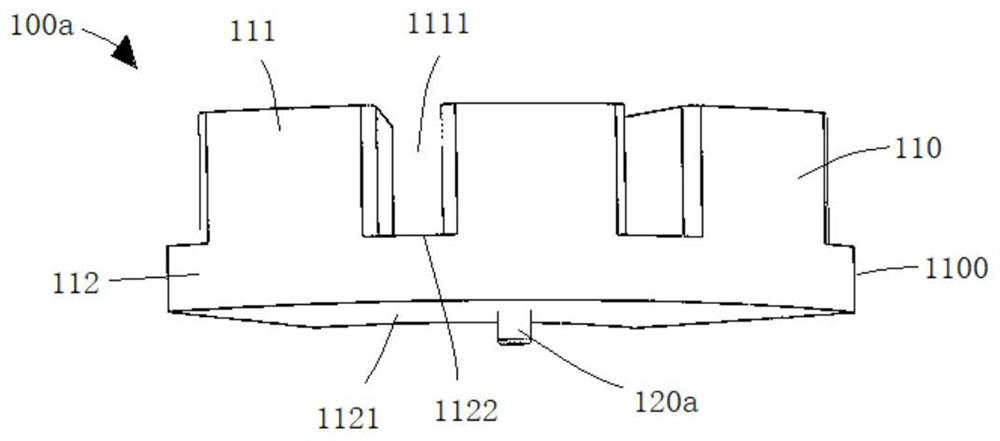

[0048] Such as Figure 1 to Figure 4 As shown, the stator core fixing structure of the axial field motor includes:

[0049] At least one iron core block 100a, the iron core block 100a includes an iron core body 110 and a connecting piece 120a, the connecting piece 120a extends outward and is integrally pressed and formed on the iron core body 110;

[0050] A casing 200, the casing 200 includes a casing bottom plate 210, the casing bottom plate 210 is provided with casing connection holes 211, the number of the casing connection holes 211 is consistent with the number of the connecting parts 120a, and one-to-one correspondence;

[0051] The iron core blocks 100a are fixed on the casing bottom plate 210 in a manner that the connecting piece 120a is connected to the casing connecting hole 211, so that the iron core blocks 100a are spliced along the circumferential direction to form a stator iron. core.

[0052] The connecting piece 120a can be a screw, which includes a conne...

no. 2 example

[0061] Such as Figure 5 to Figure 8 As shown, the stator core fixing structure of the axial field motor includes:

[0062] At least one iron core block 100b, the iron core block 100b includes an iron core body 110 and a connecting piece 120b, the connecting piece 120b extends outward and is integrally pressed and formed on the iron core body 110;

[0063] A casing 200, the casing 200 includes a casing bottom plate 210, the casing bottom plate 210 is provided with casing connection holes 211, the number of the casing connection holes 211 is consistent with the number of the connecting parts 120b, and one-to-one correspondence;

[0064] The iron core segments 100b are fixed on the casing bottom plate 210 by connecting the connecting piece 120b to the casing connection hole 211, so that the iron core segments 100b are spliced along the circumferential direction to form a stator iron core.

[0065] The second embodiment of the stator core fixing structure of the axial field ...

no. 3 example

[0070] Such as Figure 9 to Figure 13 As shown, the stator core fixing structure of the axial field motor includes:

[0071] At least one iron core block 100c, the iron core block 100c includes an iron core body 110 and a connecting piece 120c, the connecting piece 120c extends outward and is integrally pressed and formed on the iron core body 110;

[0072] A casing 200, the casing 200 includes a casing bottom plate 210, the casing bottom plate 210 is provided with casing connection holes 211, the number of the casing connection holes 211 is consistent with the number of the connecting pieces 120c, and one-to-one correspondence;

[0073] The iron core blocks 100c are fixed on the casing bottom plate 210 by connecting the connecting piece 120c to the casing connecting hole 211, so that the iron core blocks 100c are spliced along the circumferential direction to form a stator iron core.

[0074] The second embodiment of the stator core fixing structure of the axial field mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com