Fuel gas liquid separation equipment

A fuel gas and liquid separation technology, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high cost, large amount of on-site welding engineering, etc., and achieve the advantages of convenient manufacture, simple structure, and easy purging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

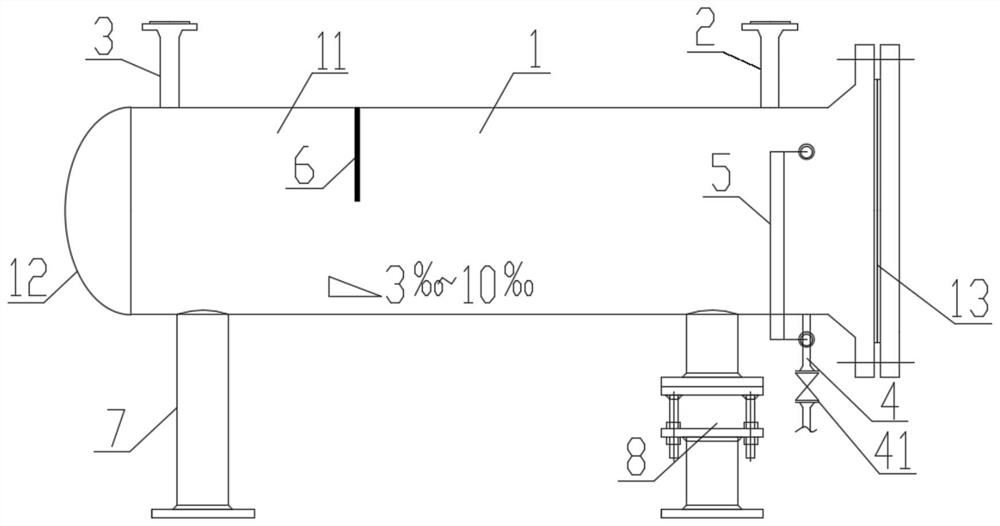

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1~3 As shown, the fuel gas liquid separation device of the present invention is mainly composed of a tank housing 1, an inlet nozzle 2, an outlet nozzle 3, a liquid discharge nozzle 4, a liquid level gauge 5, a baffle plate 6, a rigid support 7 and Adjustable support 8 forms. The tank shell of the liquid dispensing device slopes downward to the liquid discharge nozzle 4 with a slope of 3‰~10‰.

[0024] The inner diameter of the tank shell 1 is 6-20 times the diameter of the inlet nozzle 2, for example, when the diameter of the fuel gas inlet is DN80, the inner diameter of the tank shell 1 is 480-1600. The tank shell 1 is composed of a cylinder body 9 in the middle, pipe caps 10 at both ends, and a sealing structure 11 between the flange and the flange cover. The sealing structure of the flange and the flange cover is convenient for cleaning th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com