Packaging box bonding device

A bonding device and packaging box technology, which is applied in the directions of packaging, transportation and packaging, box making operations, etc., can solve the problems of loosening and detachment of packaging box parts, reduce the existence of air bubbles, increase the extrusion effect, and increase the connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

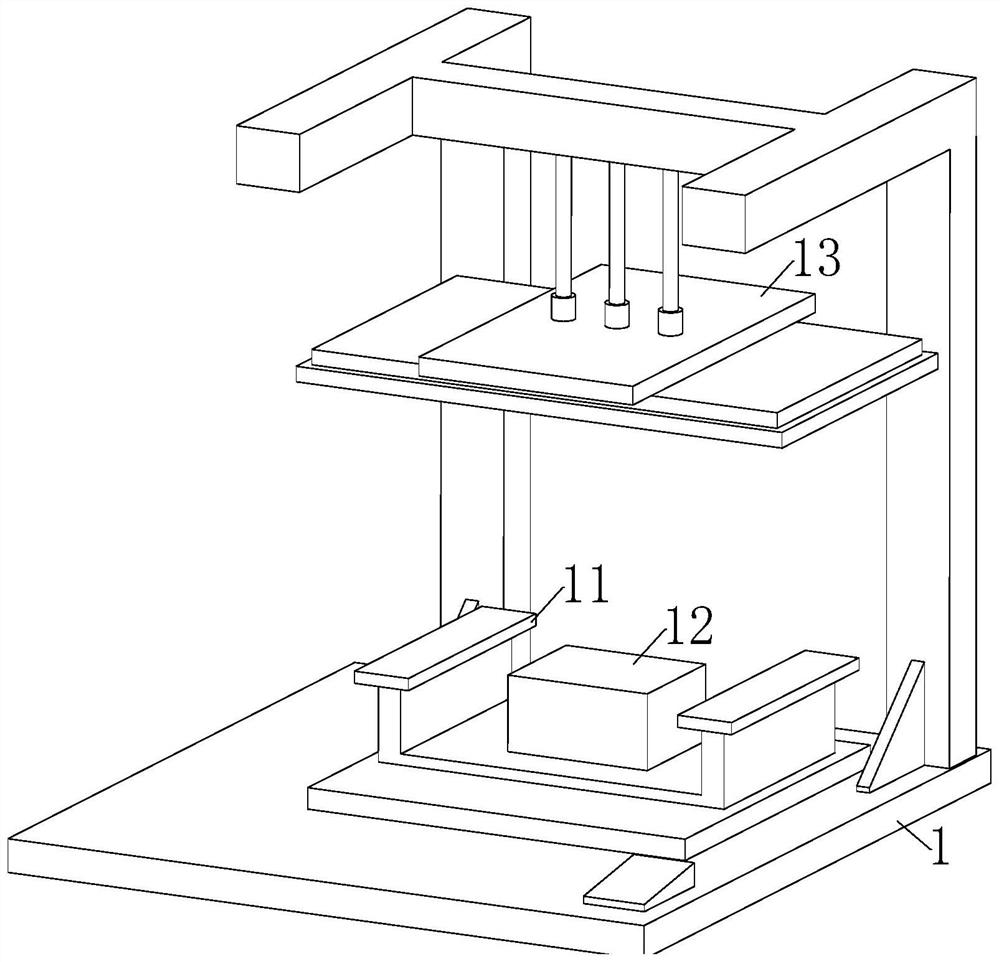

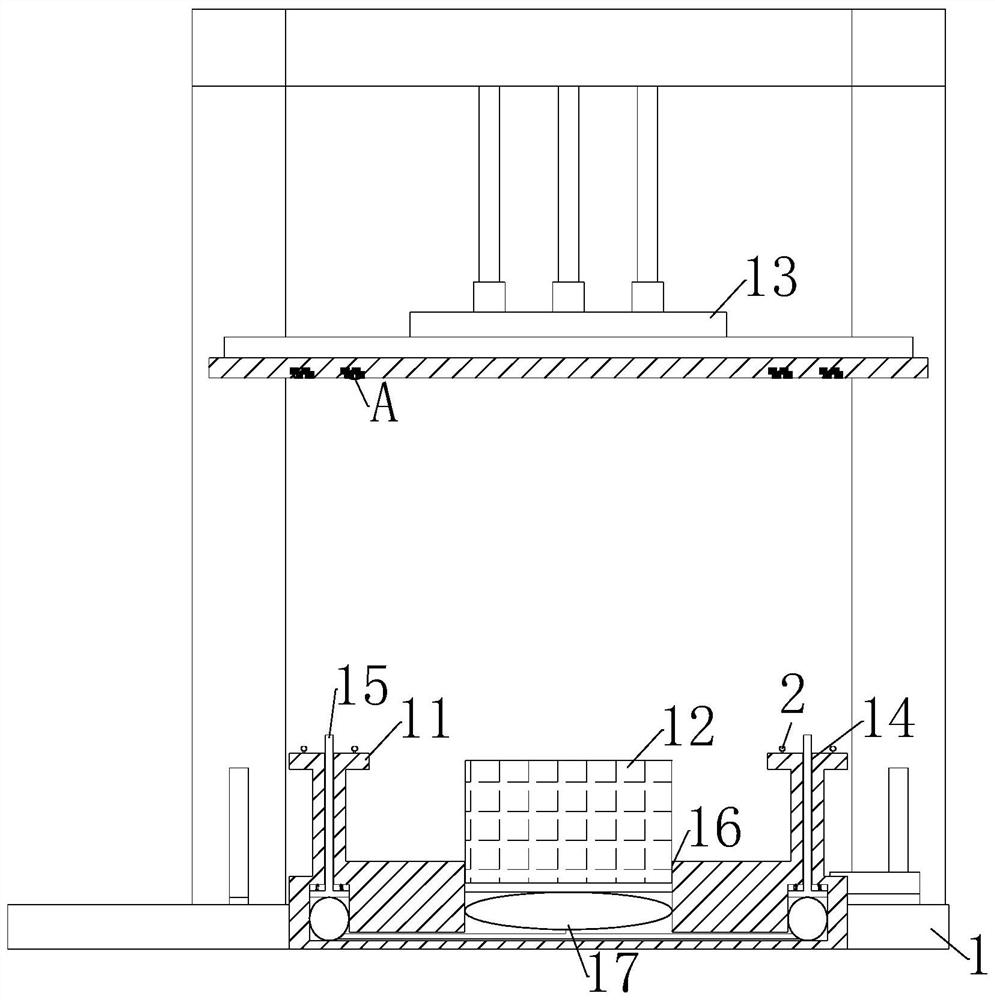

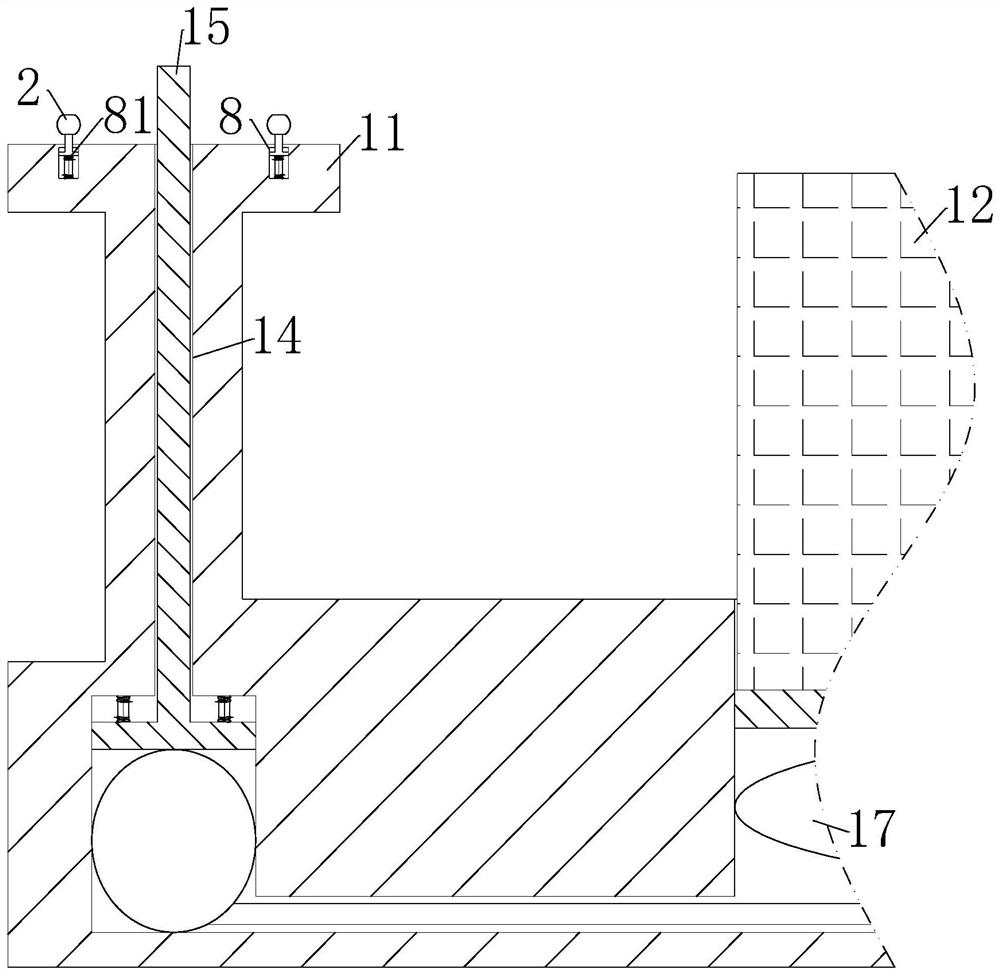

[0030] Such as Figure 1 to Figure 3 As shown, a packaging box bonding device described in the embodiment of the present invention includes a base 1; a pair of No. 1 limiting plates 11 are fixedly connected to the top of the base 1; 13. There is a No. 1 chute 14 at the top of the one-to-one number limiting plate 11; an extrusion rod 15 is slidably connected to the inside of the No. 1 chute 14; the top of the base 1 is located on the one-to-one number limiting plate 11 There is a No. 2 chute 16 between them; the inside of the No. 2 chute 16 is slidingly connected to the limit block 12; the inside of the No. 1 limiting plate 11 and the No. 2 chute 16 are fixedly connected with an air bag 17; The above-mentioned airbags 17 are connected through the air guide tube; when working, the staff will place the base 1 on the designated position, place the packaging box on the limit block 12, and squeeze it through the decline of the No. 1 squeeze plate 13 , the extrusion rod 15 will be s...

Embodiment 2

[0040] Such as Image 6 As shown in Comparative Example 1, another embodiment of the present invention is: a pair of rubber plates 3 bottoms are rotatably connected with cams 101, and arranged symmetrically; during operation, when the connecting ball 2 enters the pair of rubber plates 3, the rotation of the cam 101 can assist the entry of the connection ball 2 and provide guidance. The rotatable cam 101 can guide the connection ball 2, and at the same time, its own protrusion can make the connection ball 2 move forward when entering. Vibration further eliminates the glue bubbles between the two packaging box components, increases the product integrity of the subsequent packaging box during processing, and reduces the subsequent shedding of the two packaging box components.

[0041] When working, when working, the staff will place the base 1 on the designated position, place the packaging box on the limit block 12, squeeze it through the decline of the No. 1 extrusion plate 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com