Sand washing device applied to oil well to be repaired and capable of being driven by workover rig

A workover rig and sand washing technology, which is applied in the direction of wellbore/well parts, flushing wellbore, earthwork drilling, etc., can solve the problems of low load capacity, low pumping pressure of sand washing fluid, and low cost, so as to reduce the The effect of self-weight and reduction of storage volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

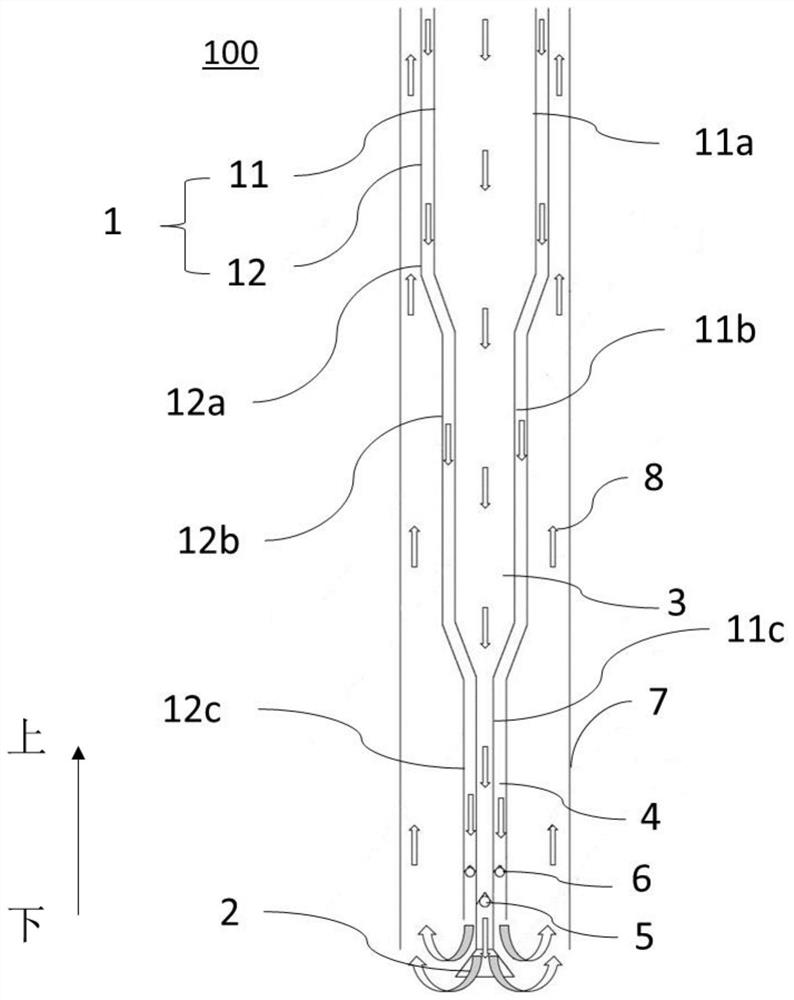

[0020] figure 1 It is a structural schematic diagram of a sand washing device 100 that is applied in an oil well to be repaired and driven by a workover rig according to an embodiment of the present invention. The sand washing device 100 includes a sand washing head 2 and is used for sending the sand washing head 2 into and A pipe string 1 arranged at the bottom of the oil well to be repaired, and a wellhead joint connecting the pipe string 1 to the workover machine. Sand flushing head 2 is used to destroy sand plugging, and it is recommended to choose a roller cone bit or a polycrystalline diamond compact bit, which has the characteristics of good wear resistance and high temperature resistance, and is easy to improve the sand washing effect. As the depth of the oil well to be repaired increases, the pipe string 1 can be extended by connecting a new pipe string 1, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com