High-frequency longitudinal combustion chamber suitable for impact type injector

An injector and combustion chamber technology, which is applied to machines/engines, jet propulsion devices, rocket engine devices, etc. High-frequency longitudinal combustion instability, the effect of facilitating high-frequency longitudinal combustion instability and avoiding the risk of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the solution of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

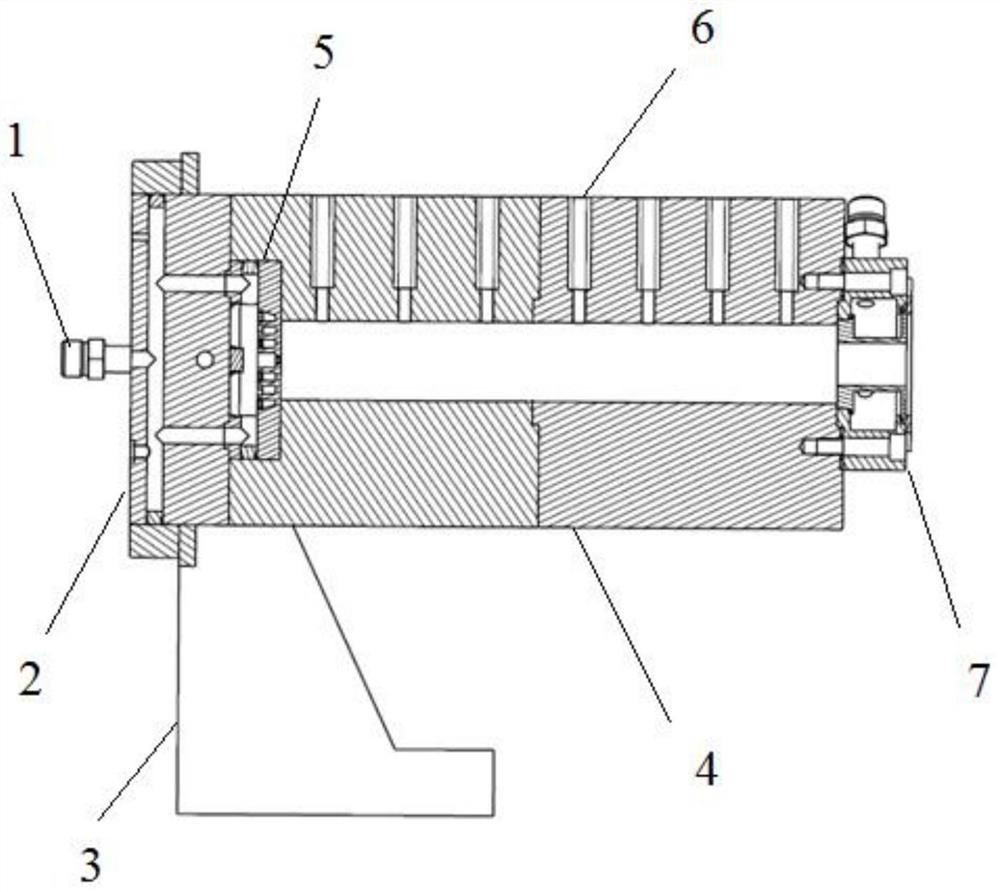

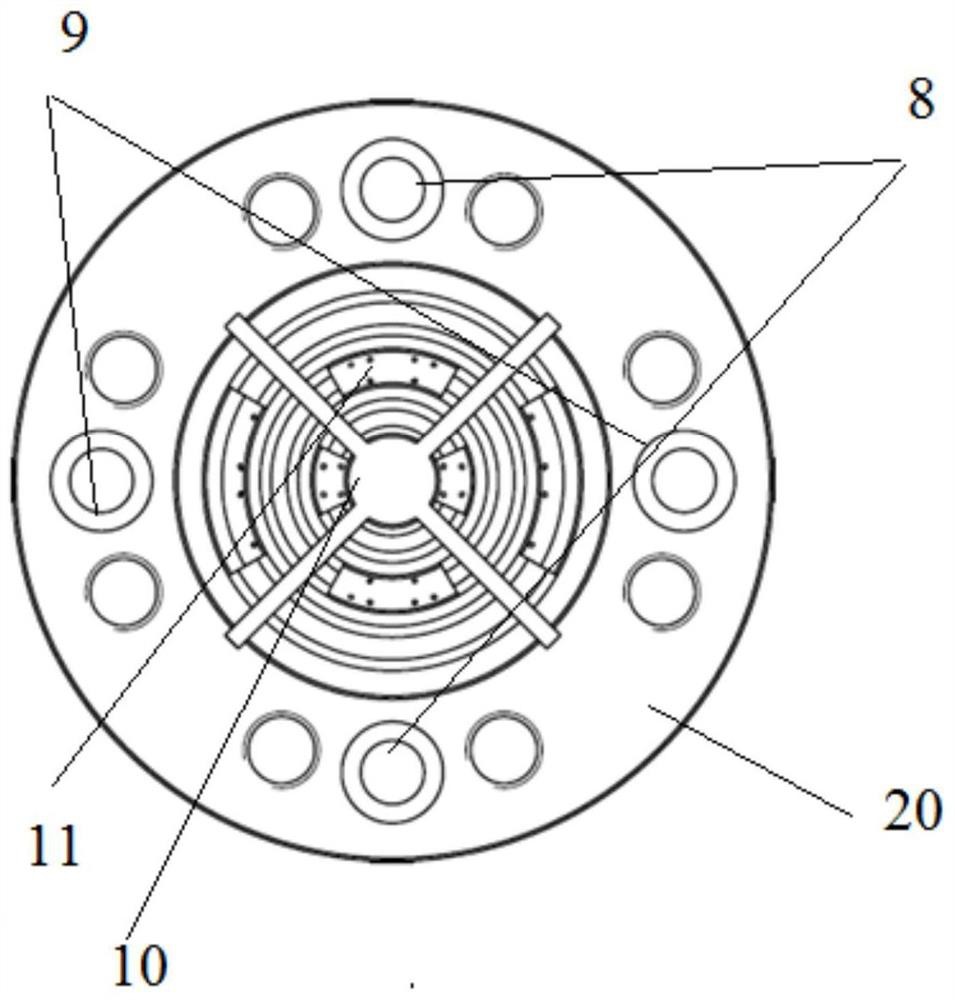

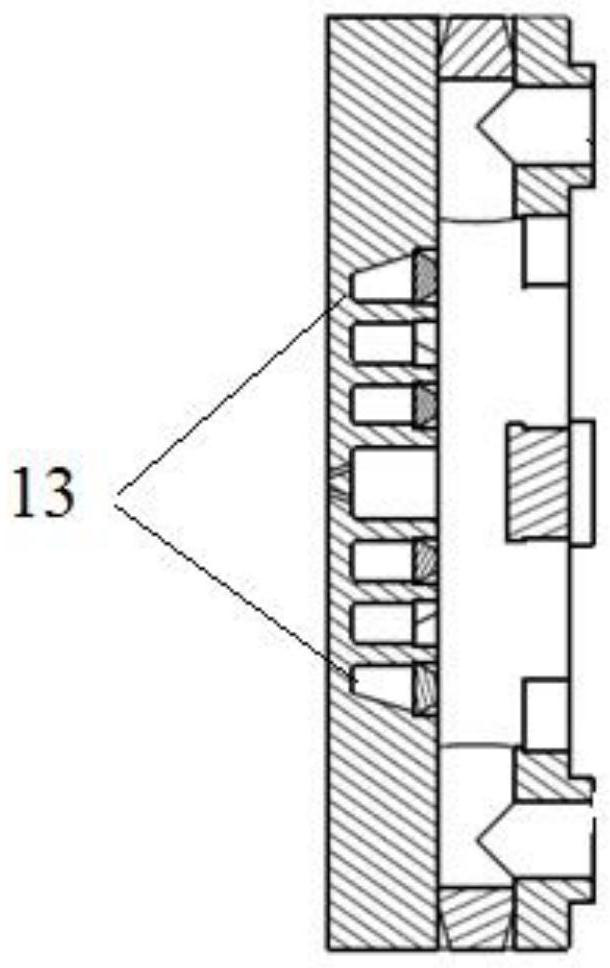

[0054] A high-frequency longitudinal combustion chamber suitable for impingement injectors, including a supply line 1 for delivering oxidant and fuel, a head adapter section 2, an independent injector 5, a combustion chamber barrel 4 and a replaceable Water-cooled throat7.

[0055] The supply pipeline 1 includes a fuel supply pipeline and an oxidizer supply pipeline. The supply pipeline 1 is connected to the front end of the head adapter section 2, and the oxidant and fuel are delivered to the independent injector through the head adapter section 2. 5, the oxidant and fuel enter the combustion chamber cylinder 4 through the independent injector 5, and the fuel and the oxidant cooperate with each other to burn in the combustion chamber cylinder 4.

[0056] A bracket 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com