Grounding type carrier

A vehicle and driving wheel technology, applied in electric steering mechanisms, vehicle components, power steering mechanisms, etc., can solve problems such as unevenness and inability to accurately locate, and achieve high mobility, simple assembly or disassembly and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

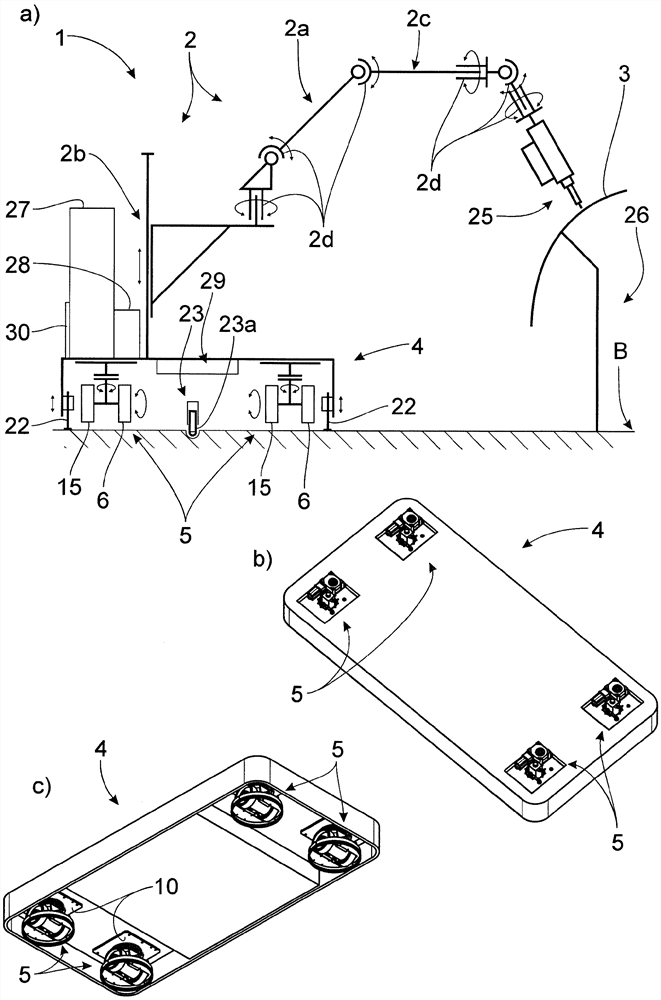

[0032] according to figure 1 The illustration in FIG. 2 shows a proposed mobile production plant 1 with a machining unit 2 for machining workpieces 3 , in particular aircraft structural components, and a proposed grounded carrier 4 . exist figure 1 In a, the production plant 1 is configured as a mobile robot platform. The grounded vehicle 4 is here a vehicle 4 that can move freely on the ground, that is to say in particular independent of the rails.

[0033] Production plants 1 of this type, in particular mobile robot platforms, are of particular importance especially when manufacturing aircraft structural components, in particular fuselage sections and / or wing sections, due to the size of these components and the precision requirements there.

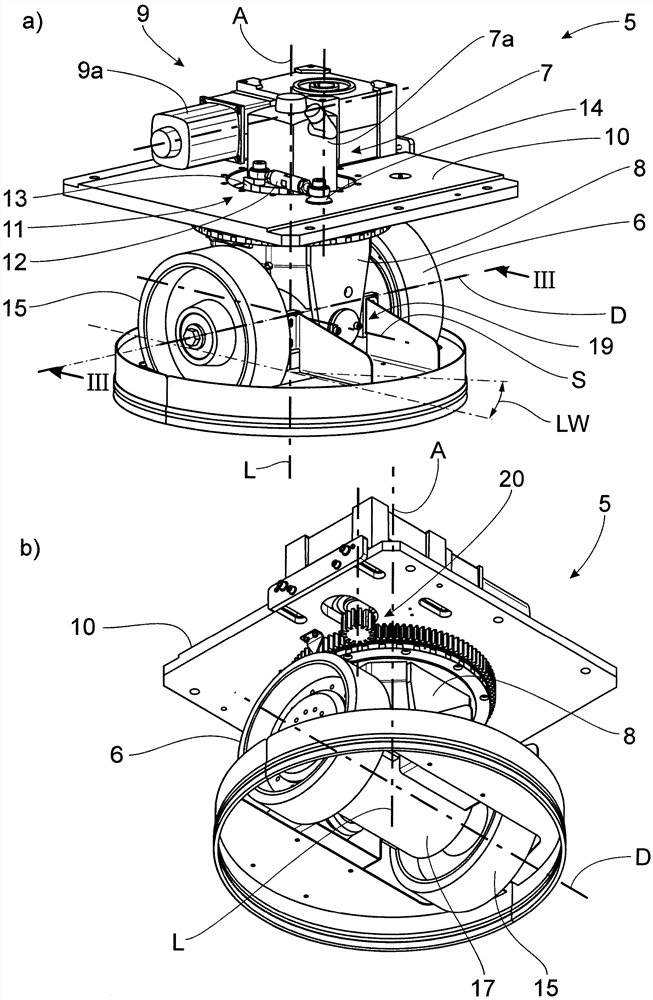

[0034] Before discussing the proposed mobile production plant 1 in more detail, the grounded carrier 4 and the drive unit 5 should first be described.

[0035] The proposed grounded vehicle 4 has at least two drive units 5 . Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com