Sugar-reduced orange compound juice and preparation method thereof

A technology of compound fruit juice and concentrated juice, which is applied in the field of fruit and vegetable juice, can solve the problems of high acidity, residual ethanol, high sugar content, etc., and achieve the effects of adjusting flavor, refreshing taste and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

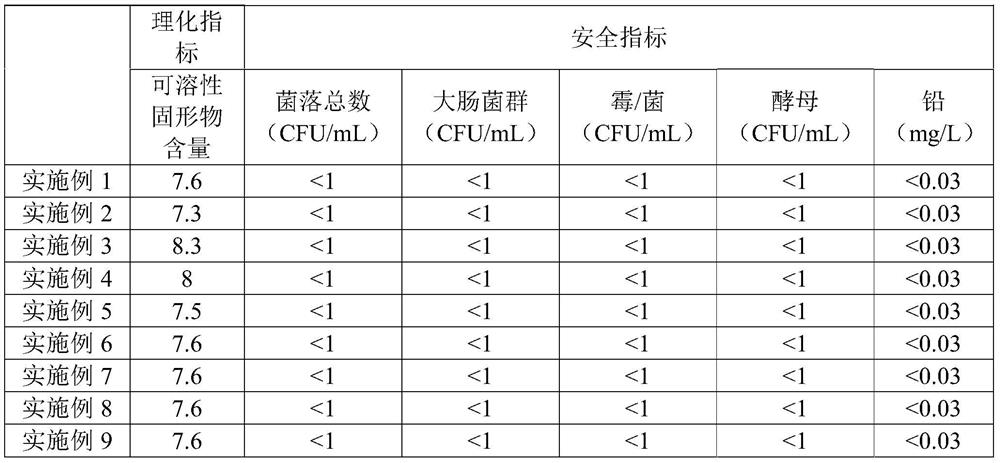

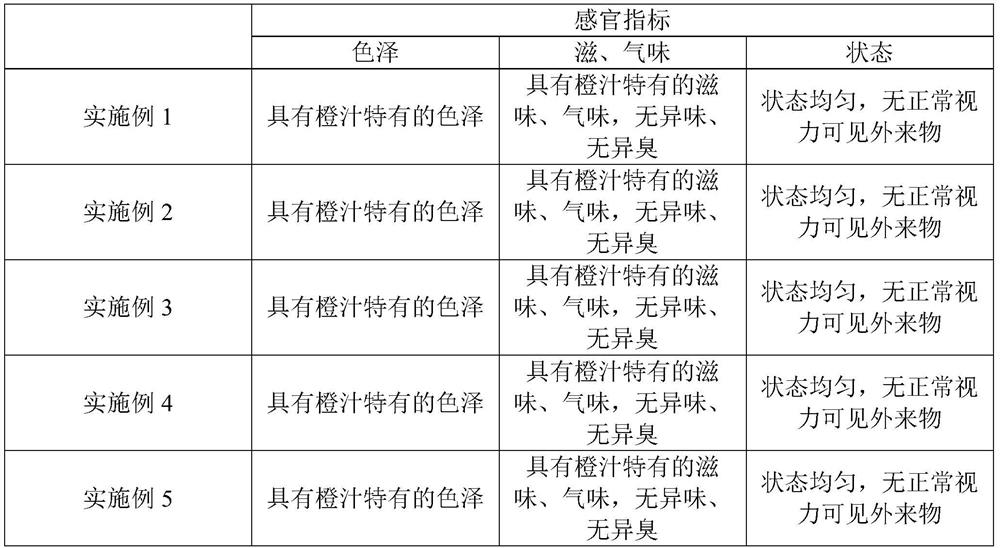

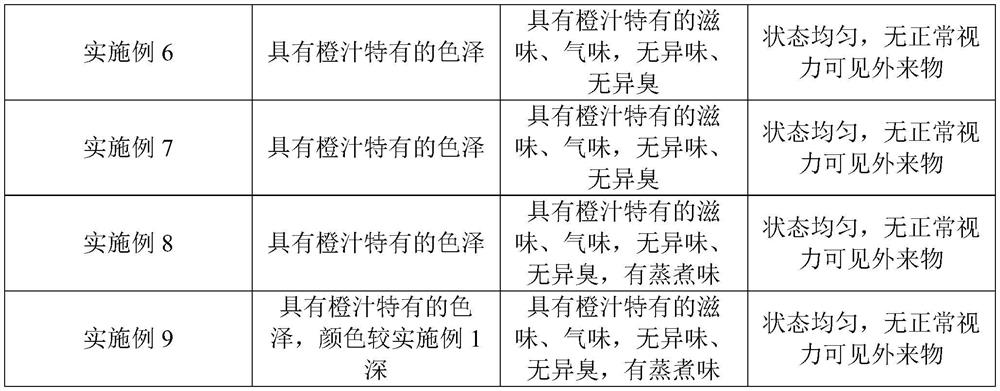

Examples

Embodiment 1

[0054] This embodiment provides a kind of reduced-sugar orange compound fruit juice, and the weight ratio of its components is as follows:

[0055] orange juice concentrate Kamen Juice Coconut water water 7% 1% 57% 35%

[0056] The preparation method is as follows:

[0057] (1) Stir and mix orange juice, Kaman orange juice, coconut water and water at 175rpm to obtain a feed liquid;

[0058] (2) Degas the feed liquid obtained in step (1) at 58° C. and -0.065 MPa to obtain a degassed feed liquid;

[0059] (3) homogenize the degassed feed liquid obtained in step (2) at 23MPa to obtain the homogeneous feed liquid;

[0060] (4) Sterilize the homogeneous feed liquid obtained in step (3) at 88° C. for 23 seconds to obtain the sterilized feed liquid;

[0061] (5) cooling the sterilized feed liquid obtained in step (4) to 17° C., and then filling to obtain the filled feed liquid;

[0062] (6) Labeling or sleeve labeling the feed liquid filled in step (5), ...

Embodiment 2

[0064] This embodiment provides a kind of reduced-sugar orange compound fruit juice, and the weight ratio of its components is as follows:

[0065] Orange juice Kamen Juice Coconut water water 6% 1% 62% 31%

[0066] The preparation method is as follows:

[0067] (1) Stir and mix the concentrated orange juice, Kaman orange juice, coconut water and water at 150rpm to obtain a feed liquid;

[0068] (2) Degas the feed liquid obtained in step (1) at 55° C. and -0.08 MPa to obtain a degassed feed liquid;

[0069] (3) homogenize the degassed feed liquid obtained in step (2) at 22MPa to obtain the homogeneous feed liquid;

[0070] (4) Sterilize the homogeneous feed liquid obtained in step (3) at 87° C. for 25 seconds to obtain the sterilized feed liquid;

[0071] (5) cooling the sterilized feed liquid obtained in step (4) to 10° C., and then filling to obtain the filled feed liquid;

[0072] (6) Labeling or sleeve labeling the feed liquid filled in step ...

Embodiment 3

[0074] This embodiment provides a kind of reduced-sugar orange compound fruit juice, and the weight ratio of its components is as follows:

[0075] Orange juice Kamen Juice Coconut water water 9% 2% 45% 44%

[0076] The preparation method is as follows:

[0077] (1) Stir and mix orange juice, Kaman orange juice, coconut water and water at 200 rpm to obtain a feed liquid;

[0078] (2) Degas the feed liquid obtained in step (1) at 65° C. and -0.05 MPa to obtain a degassed feed liquid;

[0079] (3) homogenize the degassed feed liquid obtained in step (2) at 25MPa to obtain the homogeneous feed liquid;

[0080] (4) Sterilize the homogeneous feed liquid obtained in step (3) at 85° C. for 30 seconds to obtain the sterilized feed liquid;

[0081] (5) cooling the sterilized feed liquid obtained in step (4) to 25° C., and then filling to obtain the filled feed liquid;

[0082] (6) Labeling or sleeve labeling the feed liquid filled in step (5), and then sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com