Energy-saving wet-type harmless fish meal equipment and production process thereof

An energy-saving, fishmeal technology, applied in the fields of feed, grain processing, food science, etc., can solve the problems of occupying space, labor consumption, low crushing efficiency, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

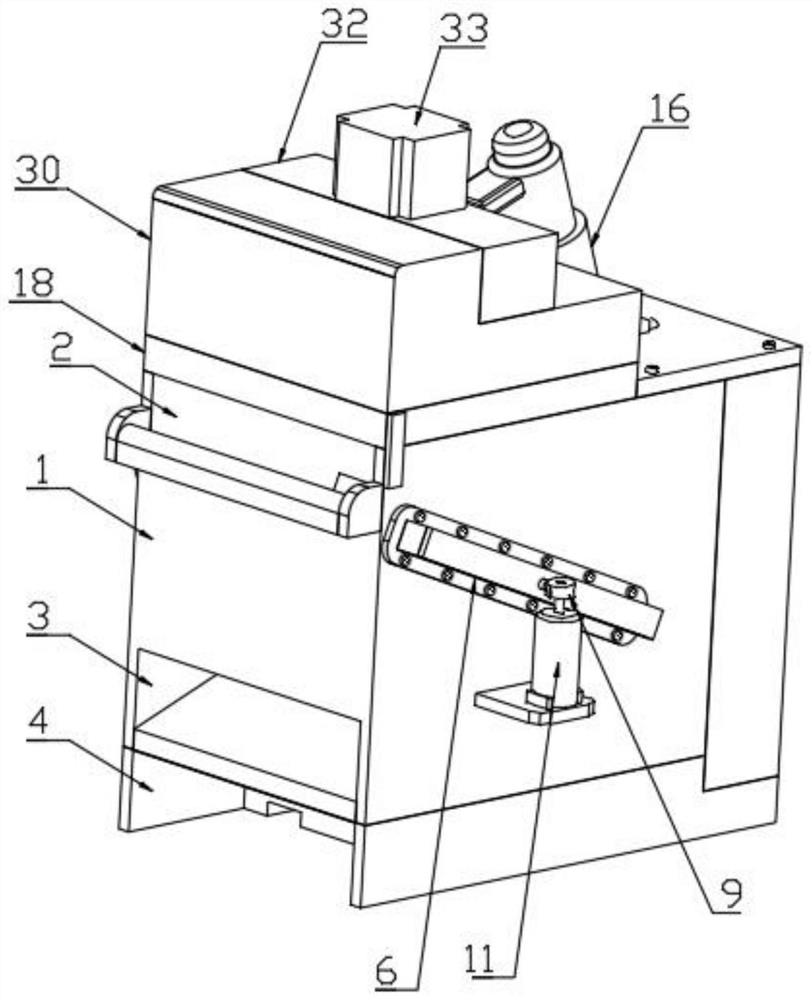

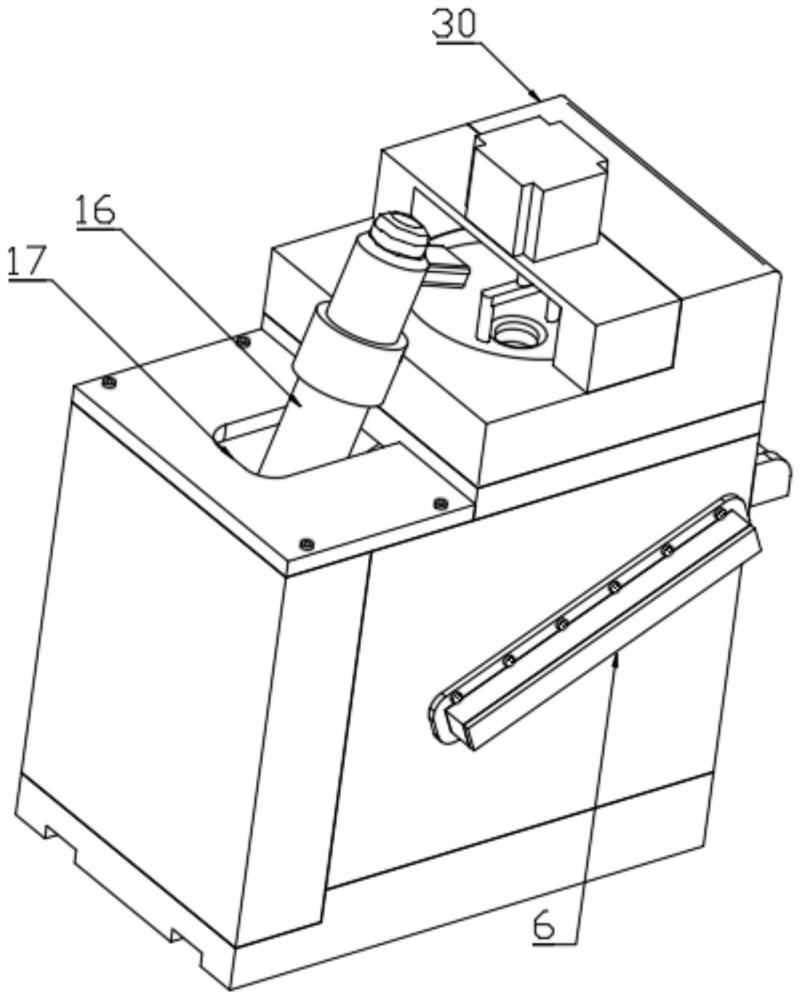

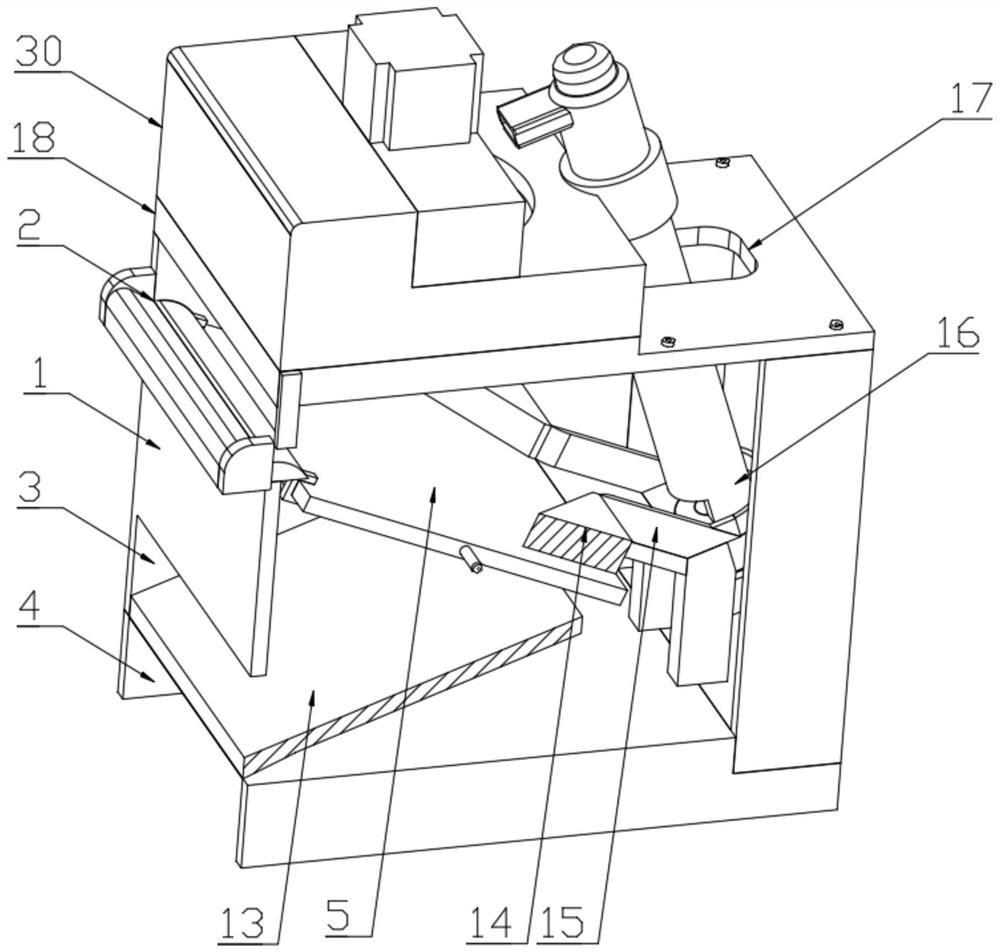

[0038] Such as Figure 1-12 As shown, an energy-saving wet-type harmless fishmeal equipment includes a fishmeal preparation machine 1, and the inside of the fishmeal preparation machine 1 is equipped with a reciprocating vibrating sieving mechanism that is inclined to the inside and has a vibrating sieve. Because the traditional fixed screening has higher efficiency, and the vibration is conducive to the sliding of coarse fishmeal to one end, the side of the reciprocating vibrating screening mechanism is equipped with an auger lifting unit 16 for collecting and transporting unscreened coarse materials, and the auger lifting unit 16 passes through The bottom is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com