Rice flour vacuum stirring and propelling device

A technology of vacuum stirring and propulsion device, which is applied in the field of stirring and propulsion device, can solve the problems of fewer eaters, easy puffing, lack of sealing mechanism, etc., and achieves the effects of increasing quality, reducing the probability of puffing, and not easy to lose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

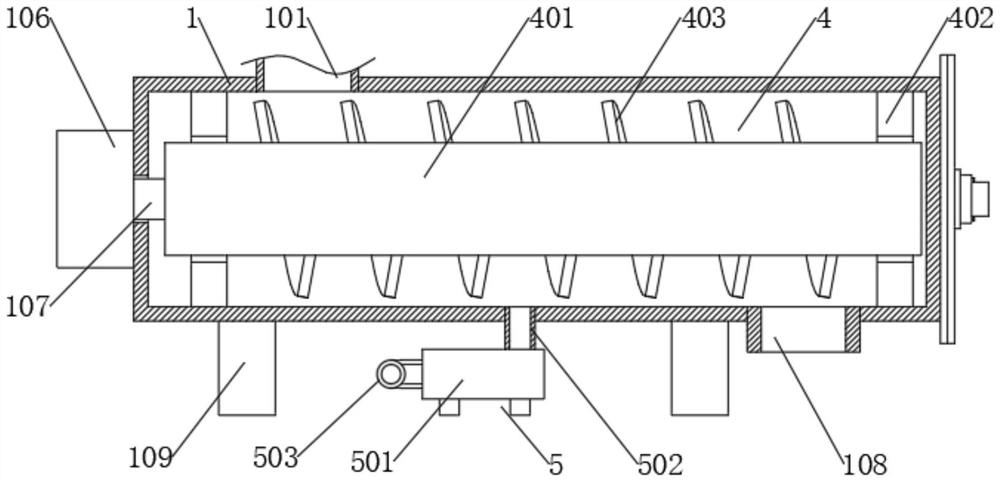

[0026] The invention discloses a vacuum stirring propulsion device for rice noodles. Figure 1-Figure 6 As shown, the mixing tank 1 is included, and the mixing tank 1 is provided with a feeding pipeline 101, which is used for the staff to put in the dough, and the feeding pipeline 101 is connected with a feeding plug 102, which is used to block the feeding pipeline 101, so that It is difficult for air to enter the mixing tank 1 from the feed pipe 101, and a chute 103 is dug on the feed plug 102 for the expansion of the first air bag 104, so that the first air bag 104 can extrude the rubber sleeve 201, the chute 103 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com