Granulator for producing chicken feed

A technology of granulator and chicken feed, which is applied in the direction of feed, raw material extrusion granulation, cleaning method using gas flow, etc., can solve problems such as troublesome operation of receiving materials, adhesion of outer rotary disc particles, shape deformation of feed particles, etc., to achieve Avoid pipeline knotting, full sealing performance, and fast wind blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

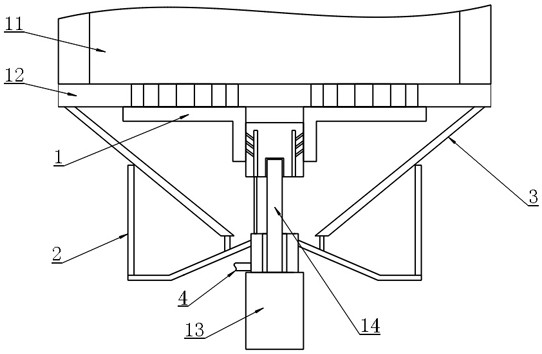

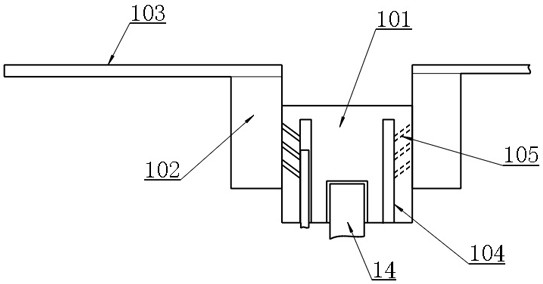

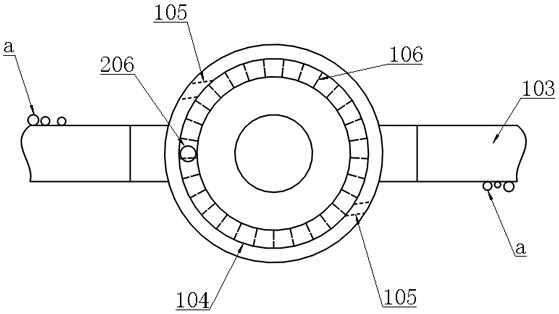

[0038] Example: as attached Figure 1-6 As shown, a pellet mill for producing chicken feed includes an extrusion cylinder 11, an orifice 12, a motor body 13, and a motor shaft 14, and also includes a hollow scraper unit arranged on the motor shaft 14 1. The vertical receiving ring unit 2 set on the motor main body 13 and socketed with the motor shaft 14, the inclined material guide ring set on the vertical receiving ring unit 2 with a large top and a small bottom unit 3, and the air inlet pipe 4 arranged on the vertical receiving ring unit 2 and connected to the hot air blower.

[0039] In this embodiment, the general usage and advantages of the granulator are as follows.

[0040] First, the extruding barrel 11 has a pusher plate that moves downward, and the opening of the orifice plate 12 is not opened at the center of the circle, otherwise the dropped feed particles will stick to the entire motor.

[0041] Second, the vertical receiving ring unit 2 and the inclined materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com