Continuous printing SLM equipment

A technology of equipment and printing device, which is applied in the field of continuous printing SLM equipment, can solve the problems of difficult printing of large 3D parts, limited printing space, and inability to move the base axis, etc., and achieves the advantages of easy printing, simple structure, and increased printing range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

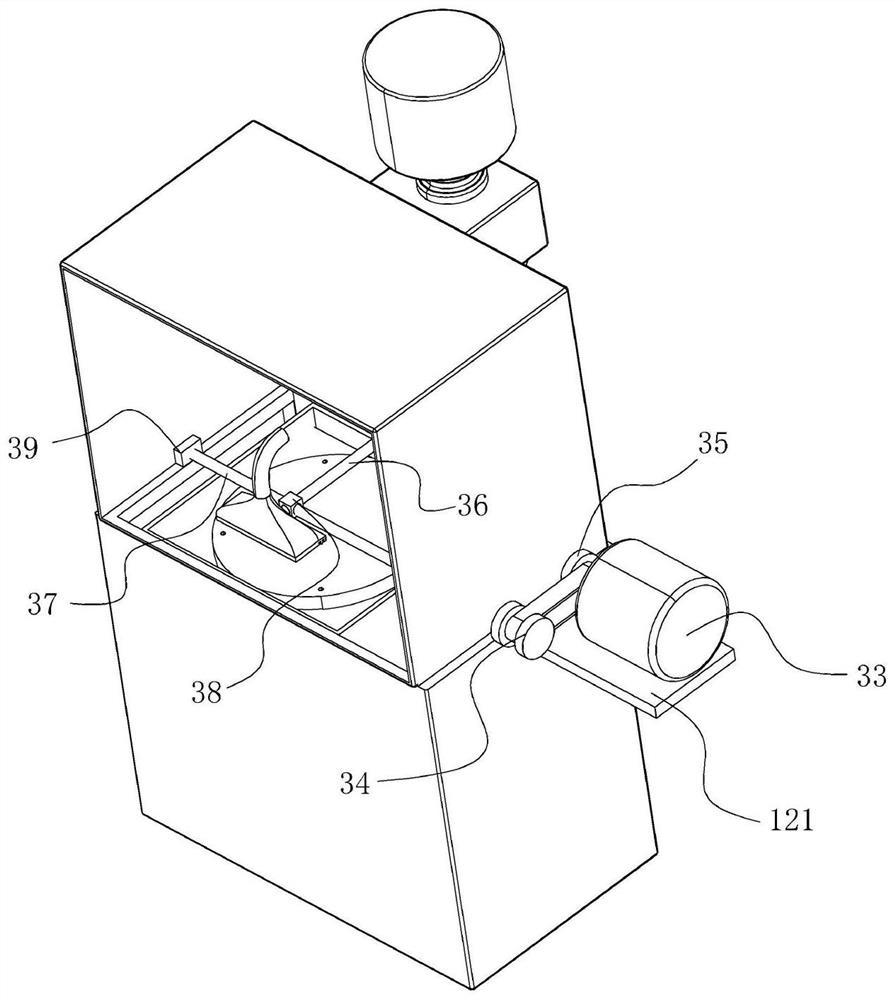

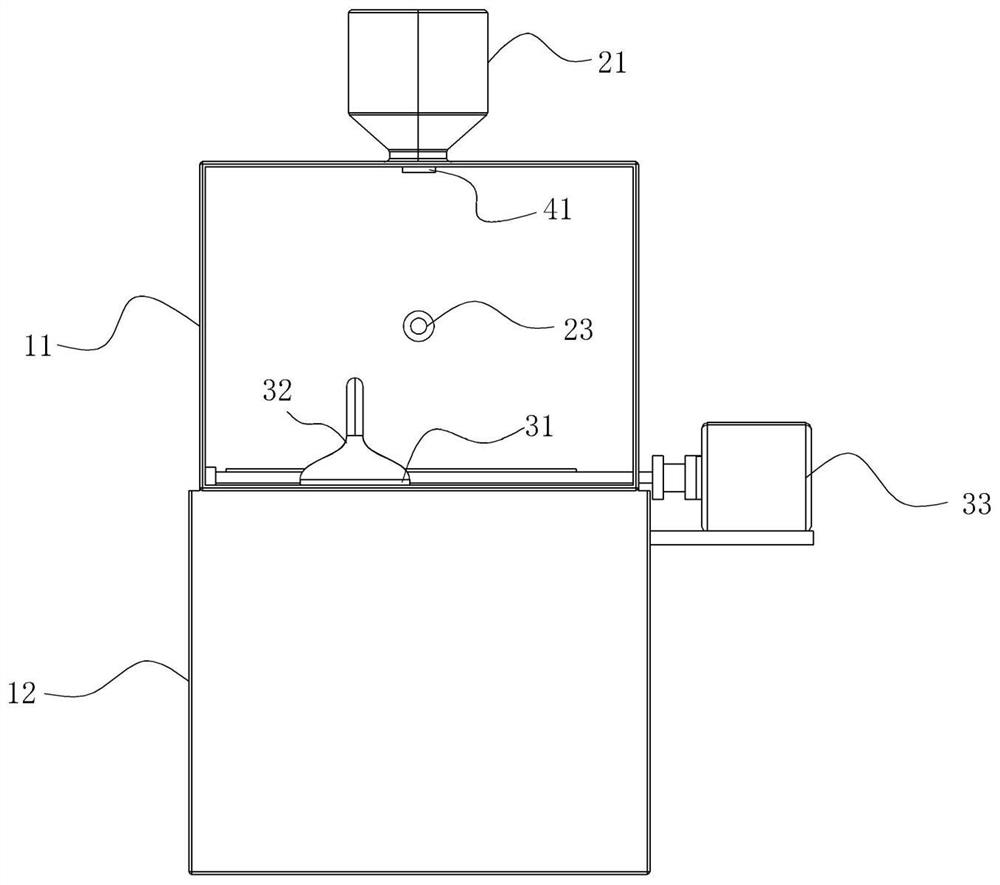

[0025] Such as Figures 1 to 5 As shown, the present invention provides a continuous printing SLM device, including a housing, a powder feeding device, a powder spreading device and a printing device;

[0026] The housing includes an upper box body 11 and a lower box body 12, a powder feeding device is provided on the rear side of the upper box body 11, an opening is provided on the front side of the upper box body 11, and a A printing device, a powder spreading device is arranged above the printing device.

Embodiment 2

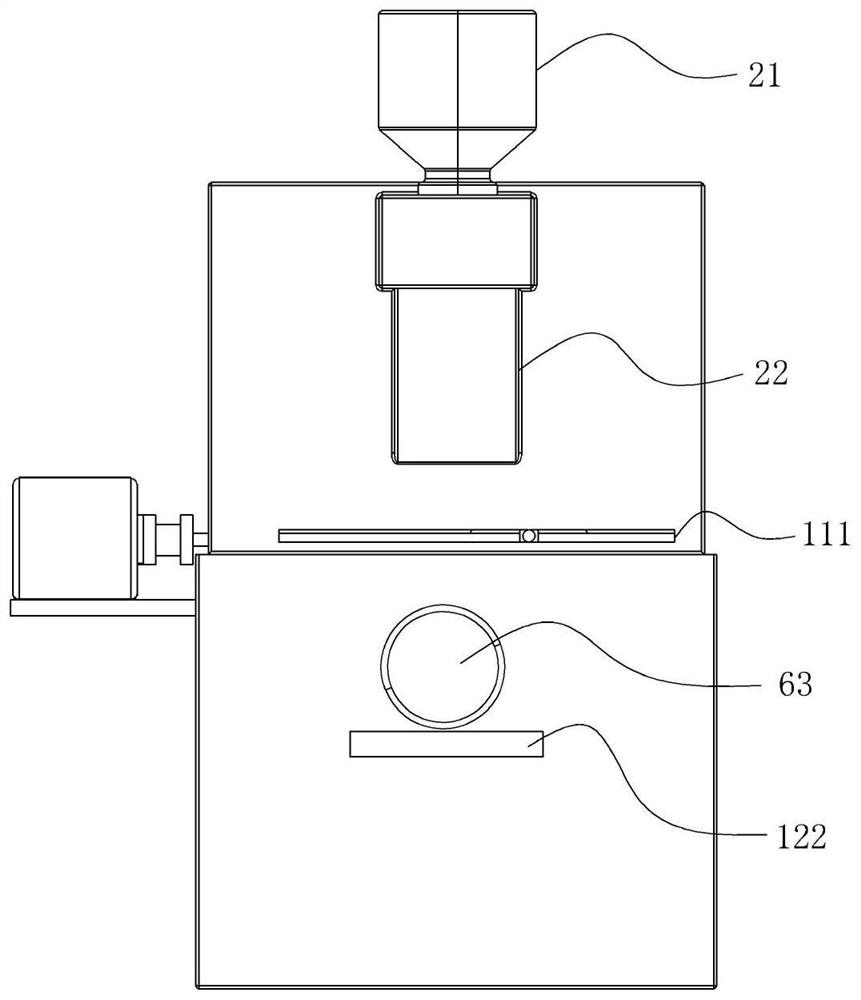

[0028] Such as Figures 1 to 5 As shown, the present invention provides a continuous printing SLM device, including a housing, a powder feeding device, a powder spreading device and a printing device;

[0029] The housing includes an upper box body 11 and a lower box body 12, a powder feeding device is provided on the rear side of the upper box body 11, an opening is provided on the front side of the upper box body 11, and a A printing device, a powder spreading device is arranged above the printing device.

[0030] Further, in another embodiment, the powder feeding device includes a powder cylinder 21, a delivery bin 22 and a powder feeding pipe; the delivery bin 22 is fixedly connected to the rear side of the upper box 11, and the top of the delivery bin 22 is provided There is a powder cylinder 21, and the inner wall of the upper box 11 is located at the conveying bin 22 and is provided with a powder feeding port 23. One end of the powder feeding pipe is connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com