PP manipulator hanging head and typesetting device using same

A technology of manipulators and lifting heads, which is applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve the problems that affect processing efficiency and the quality of PP film cannot be effectively guaranteed, and achieve the effect of improving detection accuracy and moving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

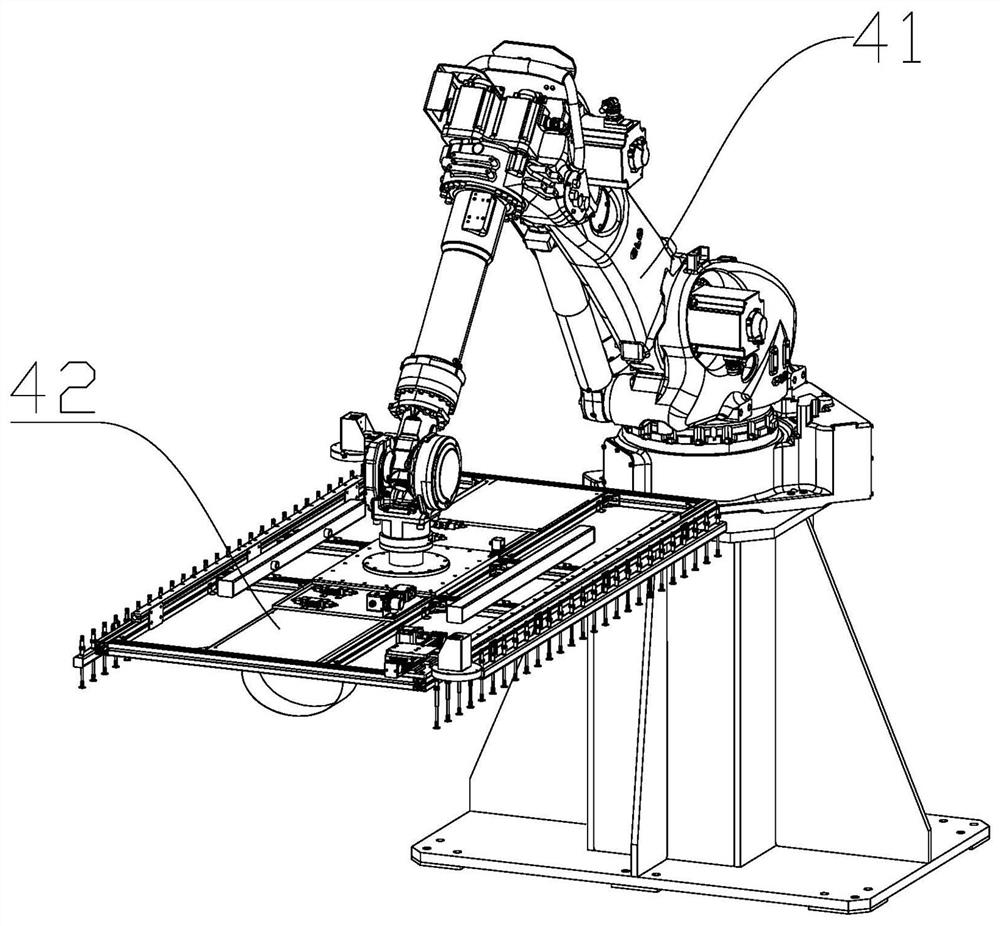

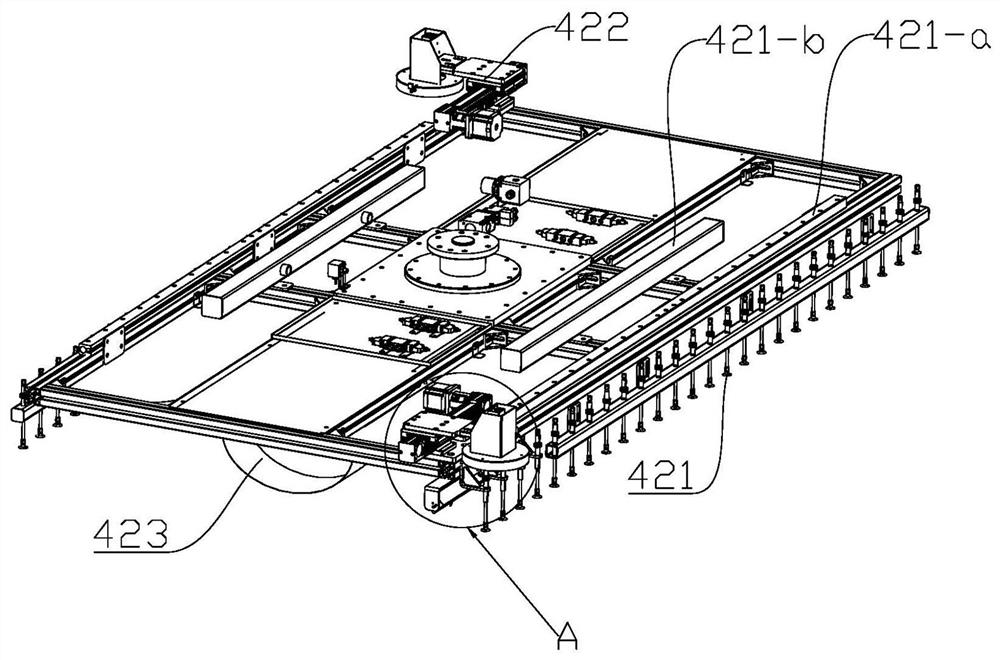

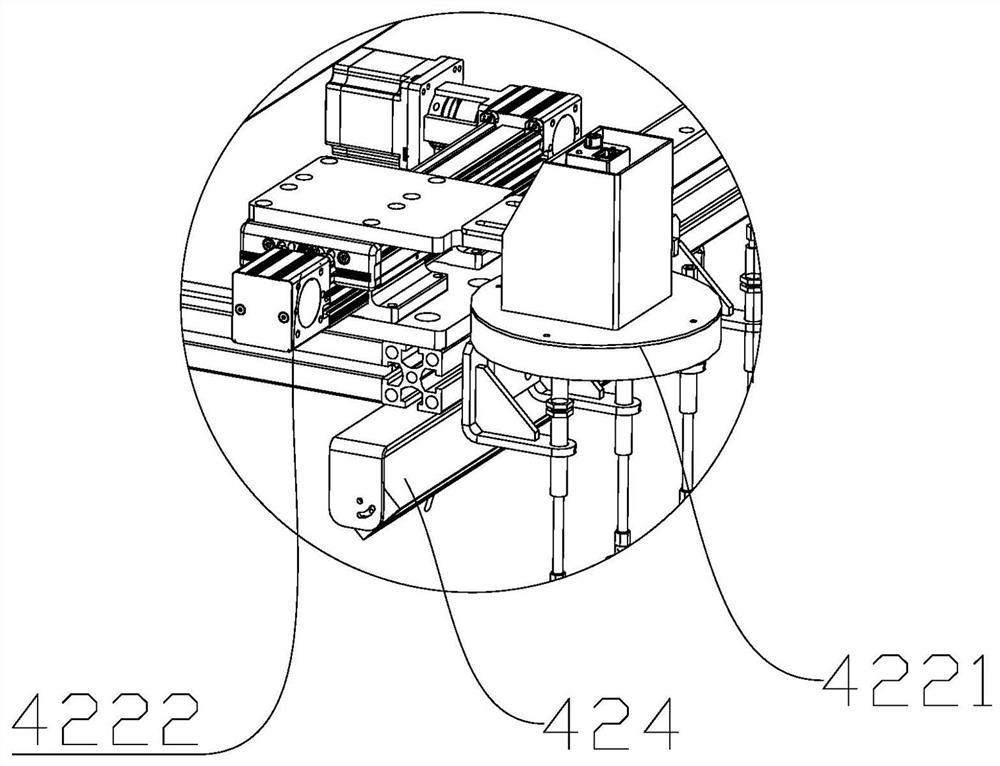

[0033] A PP manipulator lifting head, please refer to Figure 1~Figure 3 , including the manipulator assembly 41 and the suction cup frame 42 arranged on the manipulator assembly 41 and controlled by the manipulator assembly, the suction cup frame 42 is kept level with the ground as a whole, and the whole suction cup frame 42 is controlled by the manipulator assembly 41 in the process of moving Keep level with the ground; two rows of suction cups 421 are arranged on both sides of the suction cup frame 42, and each row of suction cups 421 is fixedly arranged by a positioning steel pipe. Air collecting holes, the upper end of each suction cup 421 is connected to the air collecting pipe 421-a through a soft rubber tube, and the suction cup frame 42 is also provided with a negative pressure tube 421-b, between the negative pressure tube 421-b and the air collecting pipe 421-a As above, when the air pressure in the negative pressure tube 421-b decreases, the air pressure inside the...

Embodiment 2

[0038] An automatic typesetting device, please refer to Figure 4~Figure 7 , including a storage platform 1, a first feeding platform 2, a second feeding platform 3, and a manipulator for moving PP films mentioned in the embodiment, wherein the storage platform 1 is used to place and transport out the stacked For the final PP film layer, the first feeding platform 2 is set on the left side of the storage platform 1, the second feeding platform 3 is set on the right side of the storage platform 1, and the manipulator for moving the PP film is used to move the first feeding platform The membranes on the material platform 2 or the second feeding platform 3 are transported to the storage table 1 for stacking to form a membrane stack; the membrane stack can make the stacking of the membranes on the first feeding platform 2, or It is a stack of membranes on the second feed platform 3 , or a mixed stack of membranes on the first feed platform 2 and the second feed platform 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com