Special steel composition and application thereof

A composite and special steel technology, which is applied in transportation, packaging, coating, additive manufacturing, etc., can solve problems affecting performance, high brittleness, high carbon steel is easy to crack, etc., achieve good impact resistance and improve performance and service life, the effect of solving the brittleness of high carbon steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

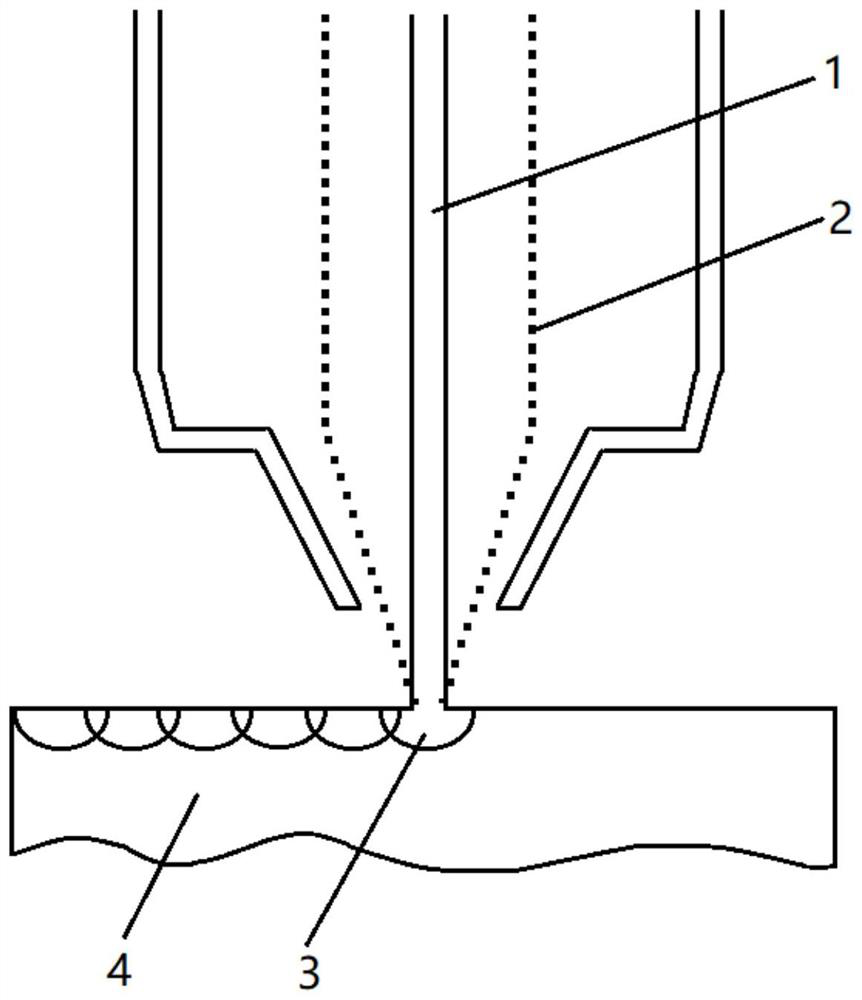

Image

Examples

Embodiment 1

[0056] The special steel composition of this example is in powder state, with a particle size of 180 μm. In proportion by weight, the elements are:

[0057] C: 0.5%,

[0058] Si: 0.6%,

[0059] Mn: 0.3%,

[0060] Mo: 4%,

[0061] Cr: 4.5%,

[0062] V: 0.6%,

[0063] Ti: 0.08%,

[0064] Al: 0.1%,

[0065] Cu: 0.05%,

[0066] Ni: 0.02%,

[0067] P≤0.006%,

[0068] S≤0.008%,

[0069] The rest is Fe.

Embodiment 2

[0071] The special steel composition in this example is in powder state, with a particle size of 80 μm. In proportion by weight, the elements are:

[0072] C: 0.55%,

[0073] Si: 0.62%,

[0074] Mn: 0.28%,

[0075] Mo: 4.3%,

[0076] Cr: 4.7%,

[0077] V: 0.6%,

[0078] Ti: 0.085%,

[0079] Al: 0.15%,

[0080] Cu: 0.055%,

[0081] Ni: 0.025%,

[0082] P≤0.006%,

[0083] S≤0.008%,

[0084] The rest is Fe.

Embodiment 3

[0086] The special steel composition in this example is in powder state, with a particle size of 120 μm. In proportion by weight, the elements are:

[0087] C: 0.52%,

[0088] Si: 0.65%,

[0089] Mn: 0.3%,

[0090] Mo: 4.5%,

[0091] Cr: 4.9%,

[0092] V: 0.62%,

[0093] Ti: 0.085%,

[0094] Al: 0.14%,

[0095] Cu: 0.055%,

[0096]Ni: 0.023%,

[0097] P≤0.006%,

[0098] S≤0.008%,

[0099] The rest is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com