Adjustable stair

An adjustable and stair technology, applied in the direction of mobile stairs, stairs, ladder-like structures, etc., can solve the problem of inconvenient transportation of large objects, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

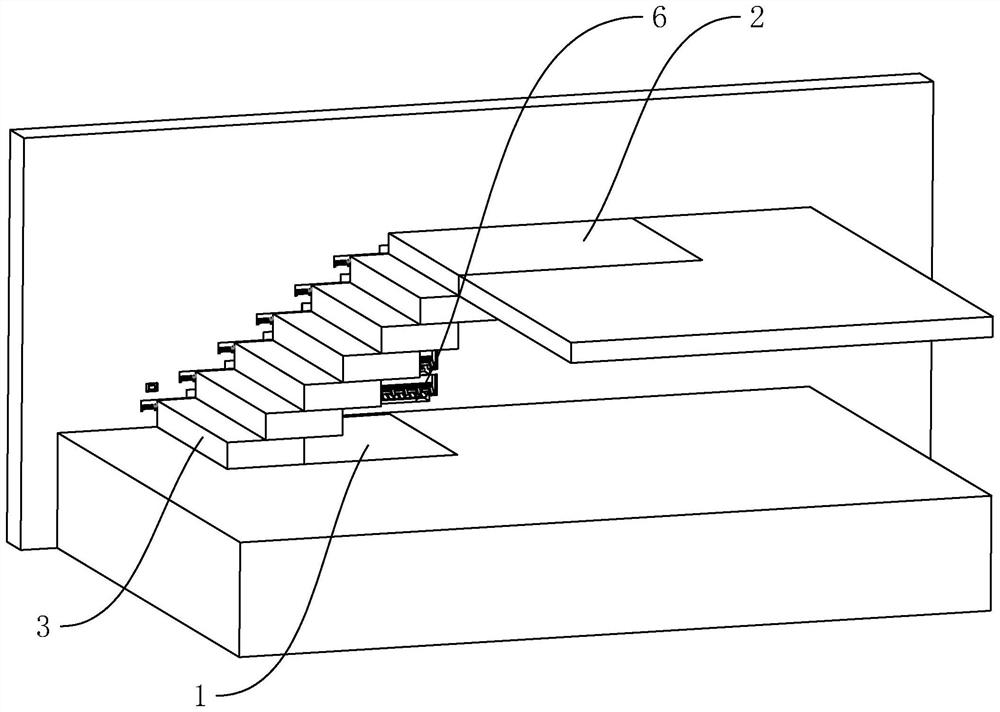

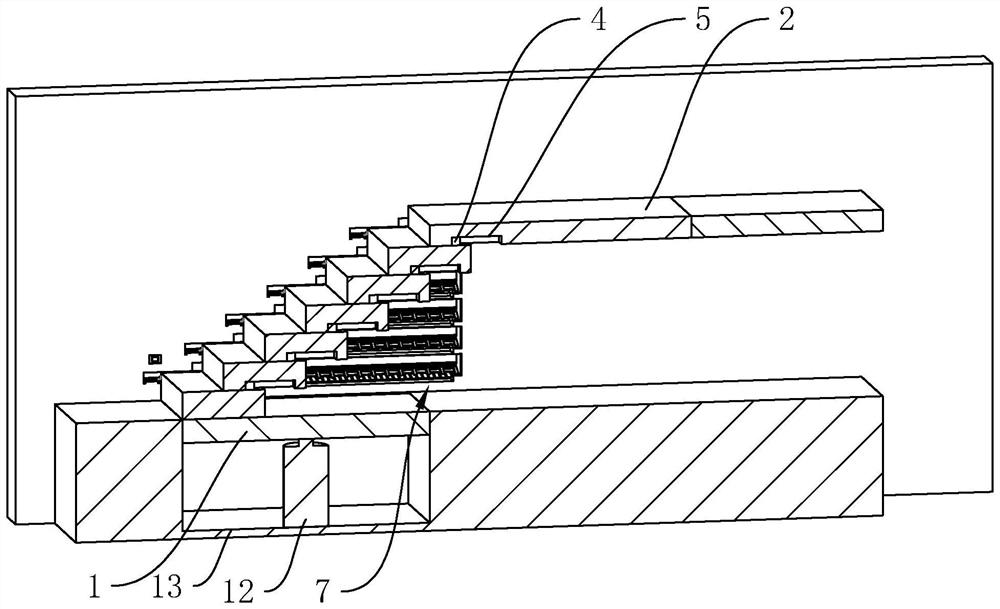

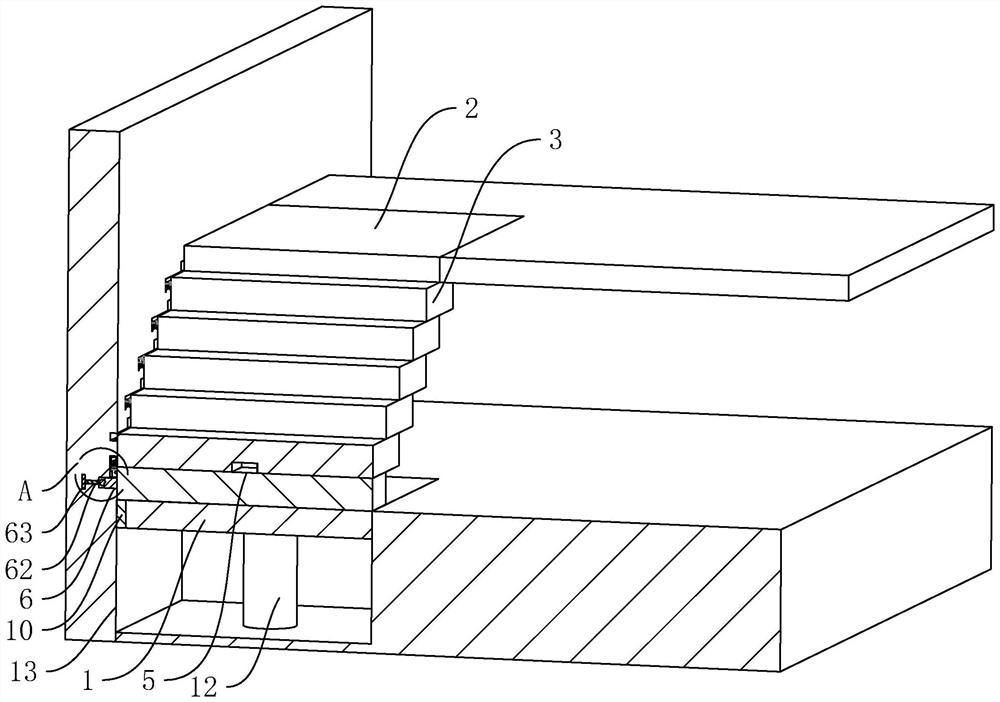

[0039] The following is attached Figure 1-8 The application is described in further detail.

[0040] The embodiment of the present application discloses an adjustable staircase. refer to figure 1 with figure 2 The adjustable staircase includes a first platform 1, a second platform 2 and several floor plates 3 located on the ground, the second platform 2 is located above the first platform 1, and several floor plates 3 are stacked in a ladder shape for connecting the first platform 1 and the The second platform 2, the first platform 1 is located at the bottom of several floors 3, and the second platform 2 is located at the top of several floors 3. The floor 3 is slidingly connected to the wall, the top of the floor 3 is poured and fixed with a limit block 4, the bottom of the floor 3 is provided with a limit groove 5, and the limit block 4 of the adjacent floor 3 is adapted to be inserted into the limit groove 5, and The length of the limiting groove 5 is equal to the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com