Pathological section device capable of realizing double-sided section

A technology of pathological section and sectioning device, applied in the field of pathological section, can solve the problems of affecting section quality, large deviation of section thickness, fracture of pathological section, etc., and achieve the effect of improving sectioning efficiency, improving sectioning precision, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

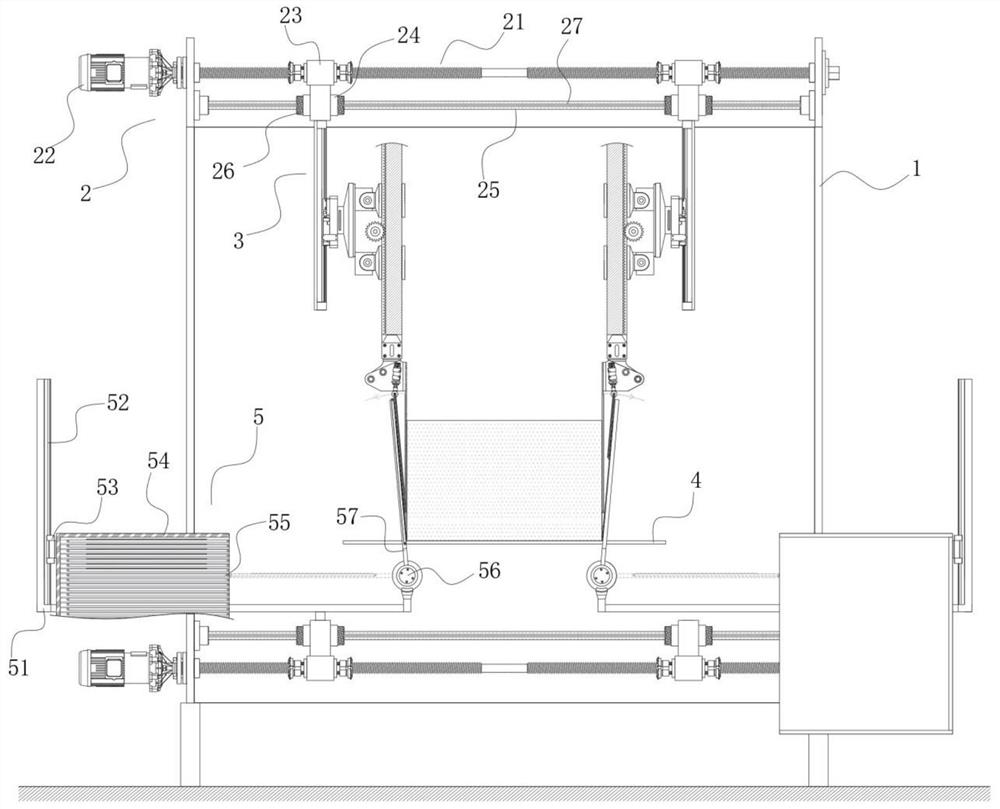

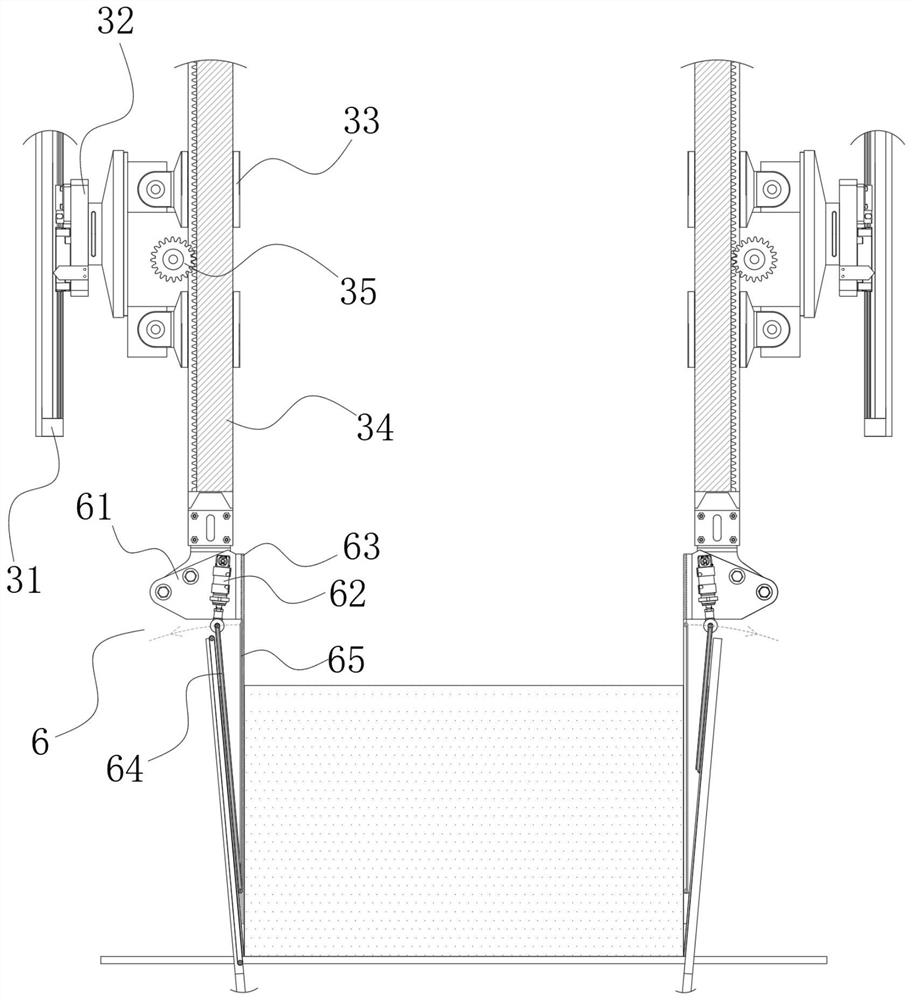

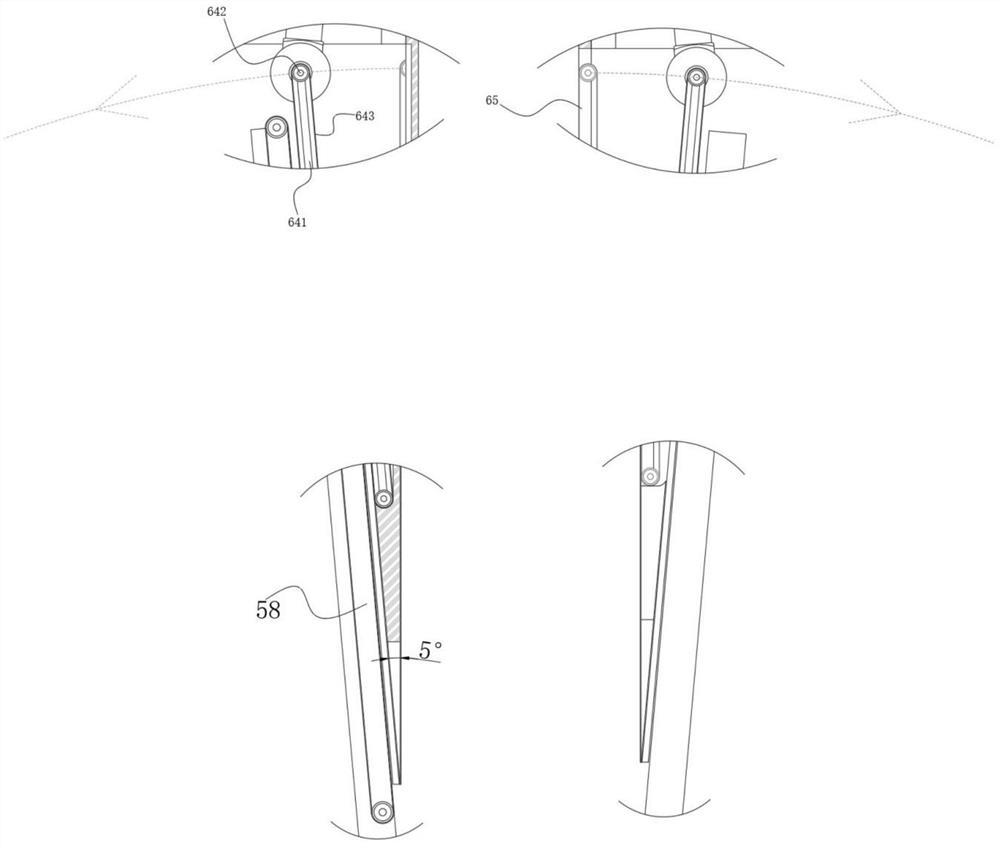

[0039] refer to Figure 1-4 , the present invention provides a technical solution: a pathological slicing device capable of double-sided slicing, which includes:

[0040] Fixed box frame 1;

[0041] The traverse device 2 is installed on the top and bottom of the fixed box frame 1, and two groups are arranged in parallel in front and rear, and the traverse device 2 on the front and rear sides of the top is equipped with a slice device 3 arranged symmetrically on the left and right. The lateral movement device 2 on the front and rear sides is equipped with a collection device 5 arranged symmetrically on the left and right;

[0042] The load strips 4 are arranged in two groups front and back, located in the middle of the slicing device 3 on the left and right sides, and fixed on the front and rear side walls near the bottom of the fixed box frame 1, for placing pathological samples.

[0043] In this embodiment, a group of said traverse devices 2 includes:

[0044] Screw rod 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com