Coal blending combustion method based on multi-objective optimization

A multi-objective optimization and coal blending technology, applied in multi-objective optimization, constraint-based CAD, design optimization/simulation, etc., can solve the problem of rough coal blending schemes, inability to fully reflect the safety and environmental protection of coal blending schemes, Unable to guarantee the applicability of coal blending and burning, etc., to achieve the effect of reducing power generation costs and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, a detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

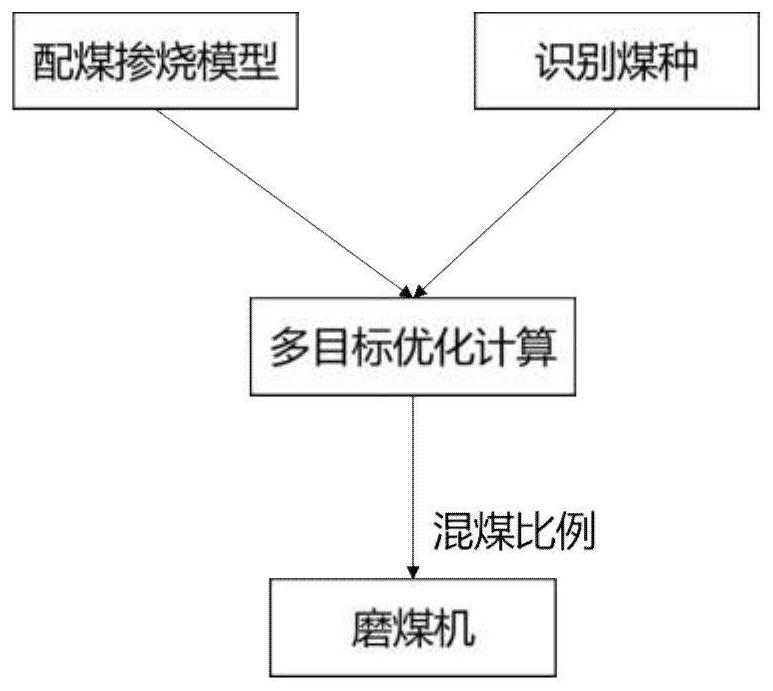

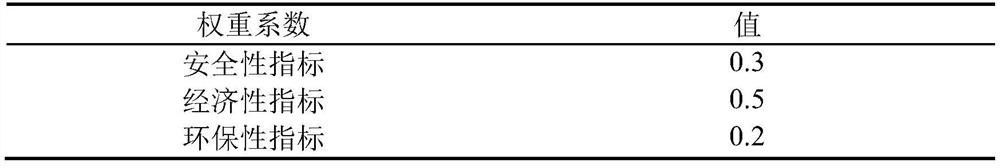

[0026] The invention discloses a method for coal blending and blending combustion based on multi-objective optimization. Under the multi-objective requirements of safety, economy and environmental protection, the actual load of the unit, the combustion conditions of the boiler and the coal storage situation in the coal yard are integrated, and the optimal calculation is carried out into the furnace blending method. Coal blending ratio, according to the blending ratio, automatically adjusts the coal feeder to control the coal type ratio, and realizes automatic coal blending and blending.

[0027] Taking a 660MW unit in a certain power plant as an example, the technical solution of the present invention will be described in detai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com