Antifouling column type porcelain insulator

A technology of porcelain insulators and insulators, which is applied in the field of anti-pollution post-type porcelain insulators, can solve the problems of inflexible use and insufficient anti-pollution ability of insulators, and achieve the effect of simple structure, guaranteed safety, and guaranteed creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

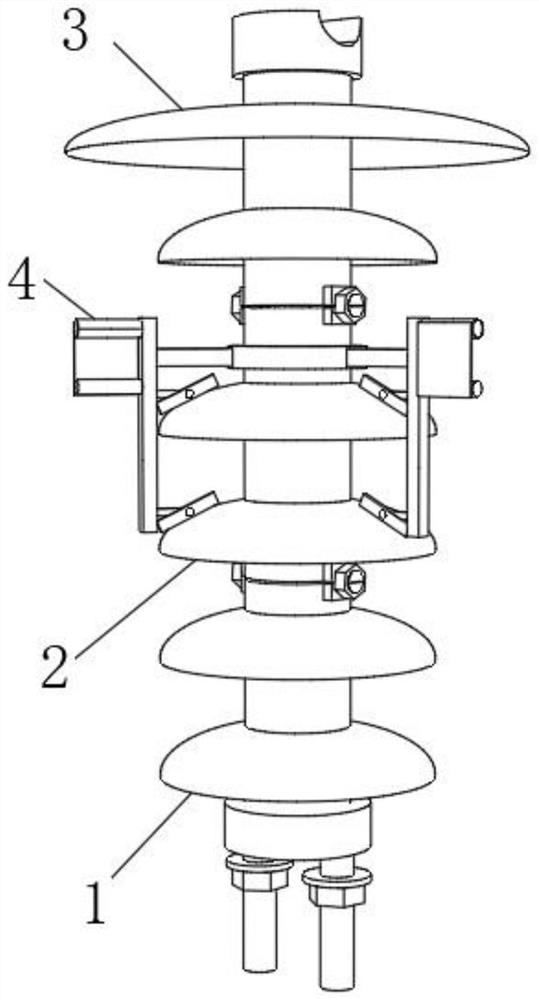

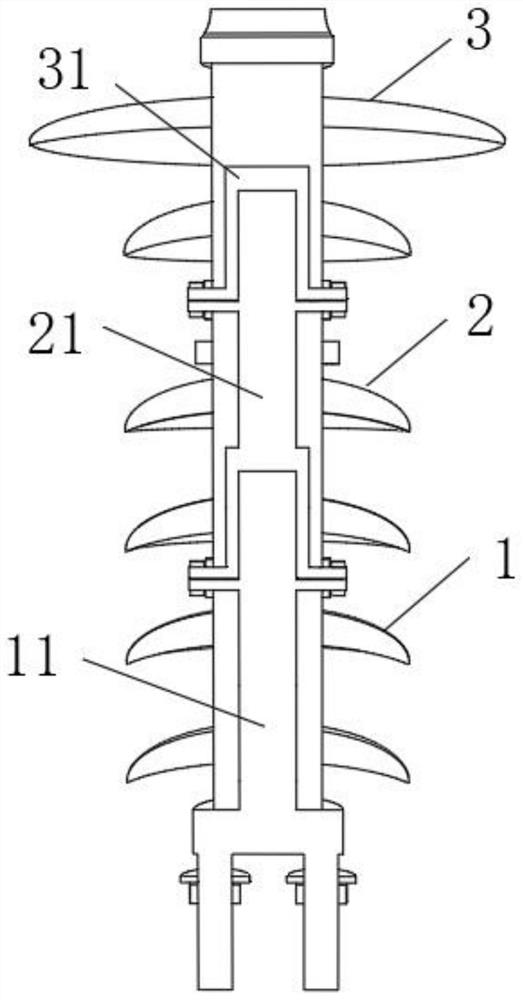

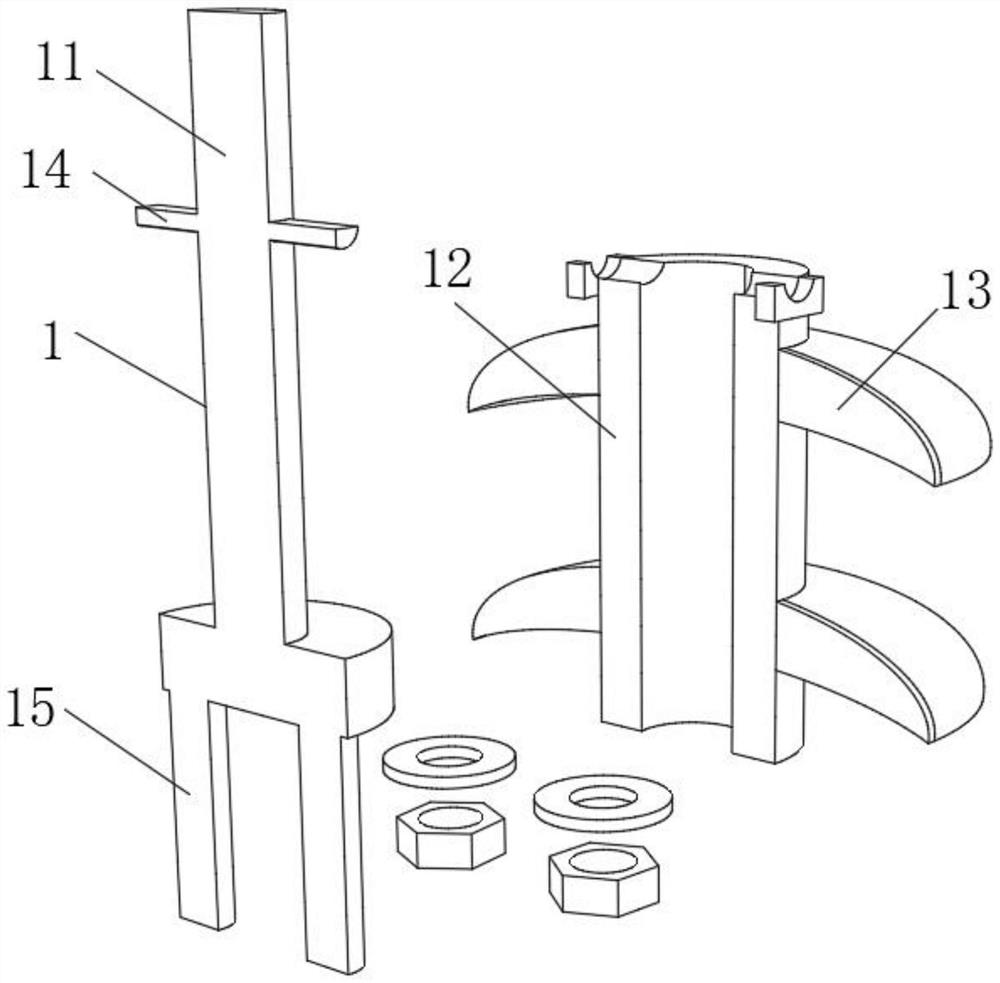

[0033] Such as Figure 1-8 As shown, the embodiment of the present invention provides an anti-pollution column type porcelain insulator, including a bottom assembly 1, an extension assembly 2, a top assembly 3 and a cleaning assembly 4,

[0034] The bottom assembly 1 is arranged at the bottom of the insulator and is used for connecting with the pole;

[0035] The extension assembly 2 is used to extend the height of the insulator;

[0036] Top assembly 3 is used as a fixed cable;

[0037] The cleaning assembly 4 is arranged outside the extension assembly 2 for cleaning the outside of the extension assembly 2;

[0038] Cleaning assembly 4 comprises bearing 41, and the outer ring of bearing 41 is evenly provided with a plurality of crossbars 42 a week, and the end of crossbar 42 far away from bearing 41 is all fixedly connected with upright bar 43, and upright bar 43 is far away from the side upper part of crossbar 42. Fixedly connected with a rotating shaft 44, the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com