Cuprous oxide nanoparticle functionalized cellulose hydrogel as well as preparation method and application thereof

A cellulose hydrogel and nanoparticle technology, which is applied in cellulose coatings, antifouling/underwater coatings, biocide-containing paints, etc., can solve the adverse effects of nanocomposite gel mechanical properties and weaken the polymer chains Problems such as cross-link density and weak interaction can solve the effects of anti-fouling broad-spectrum, increase cross-link density, and strengthen mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

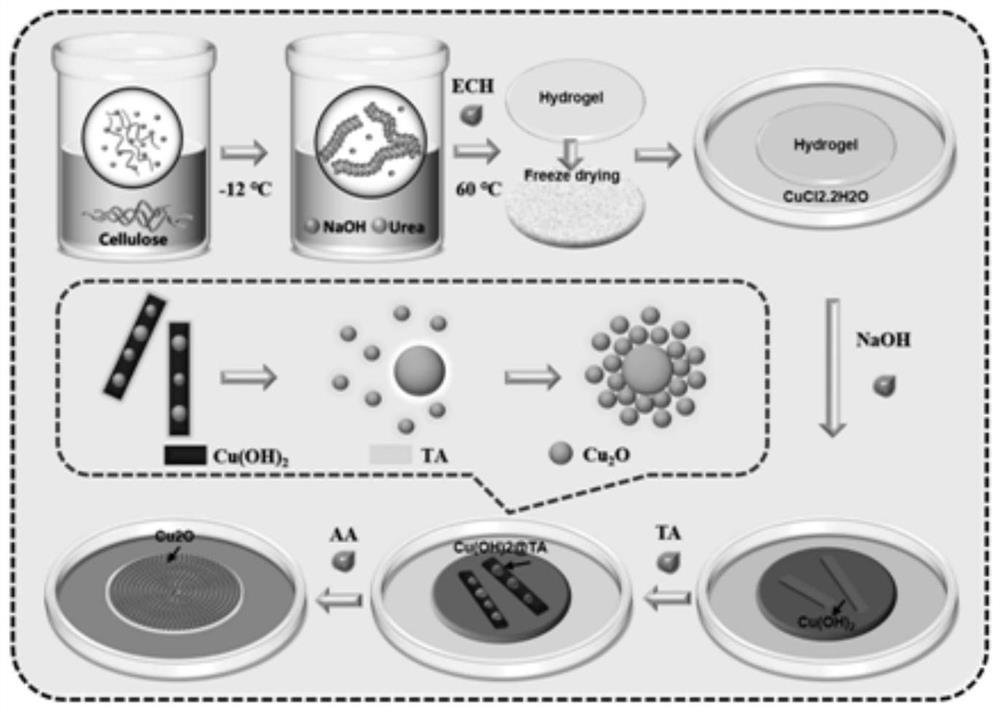

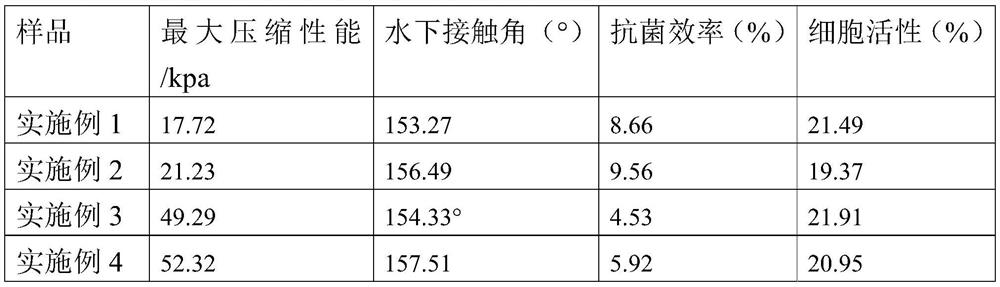

[0050] This embodiment provides a method for doping cuprous oxide (Cu 2 O) prepared cuprous oxide nanoparticle functionalized cellulose hydrogel, the preparation method comprises the following steps:

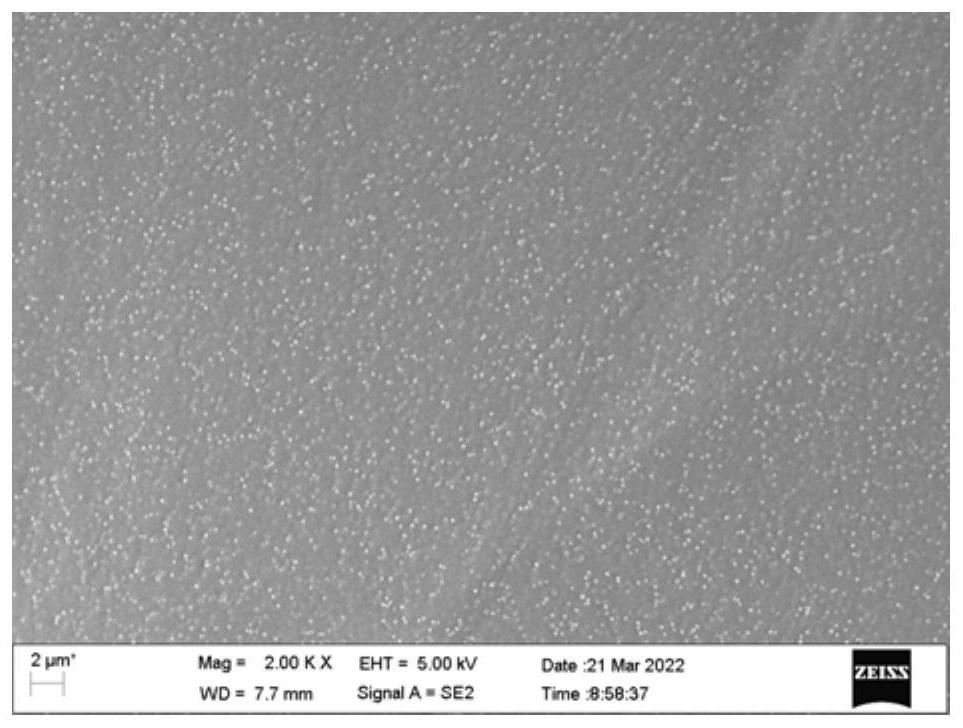

[0051] (1) Prepare 80mL of 0.05mol / L copper sulfate dihydrate (CuSO 4 ·2H 20) solution, add 20mL 2mol / L sodium hydroxide solution dropwise, after the reaction for 2h, wait for the blue precipitate to separate out completely, add 0.88g ascorbic acid and stir for 2h, until the precipitate becomes orange-yellow, the precipitate is centrifuged (3500r / min, 15min ) and then washed with deionized water for 5 times until neutral to remove the residual impurities on the surface of the precipitate and inside, and finally the precipitate was centrifuged (3500r / min, 15min) and freeze-dried for 2 days to obtain cuprous oxide (Cu 2 O) Nanoparticles.

[0052] (2) Weigh 40g of cellulose solution, add 4mL of epichlorohydrin, then add 0.5g of cuprous oxide nanoparticles prepared in step (1), s...

Embodiment 2

[0054] The present embodiment provides a cuprous oxide nanoparticle-functionalized cellulose hydrogel prepared by doped tannic acid-encapsulated cuprous oxide nanoparticles by means of physical blending. The preparation method includes the following steps:

[0055] (1) Prepare 80mL 0.05mol / L copper sulfate dihydrate solution, add dropwise 20mL 2mol / L sodium hydroxide solution, react for 2h and wait for the blue precipitate to completely separate out, add 0.2g tannic acid and stir for 1h, wait for precipitation After completely turning into dark green, add 0.88g ascorbic acid and stir for 2h until the precipitate turns orange-yellow. The precipitate is centrifuged (3500r / min, 15min) and washed with deionized water for several times until it is neutral to remove the surface and interior of the precipitate. For the remaining impurities, the precipitate was finally centrifuged (3500 r / min, 15 min) and then freeze-dried for 2 days to obtain tannic acid-encapsulated cuprous oxide nan...

Embodiment 3

[0058] The present embodiment provides a pure cellulose hydrogel, and the preparation method includes the following steps:

[0059] Weigh 40 g of cellulose solution, add 4 mL of epichlorohydrin, stir at 30 °C for 30 minutes, and then place it in a 60 °C water bath and heat for 1 h to obtain a cellulose hydrogel. The hydrogel was soaked and washed in deionized water for 4 days, during which the water was changed every 8 h to remove the residual impurities on the surface and inside of the cellulose hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com