Composite anti-fouling anti-ultraviolet heat insulation polyester film and preparation method thereof

A technology of heat insulation and polyester film, which is applied in the field of polyester film, can solve the problems of oleophobic properties of ester films and poor thermal insulation performance, and achieve the effect of excellent super oleophobic properties and strong super hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

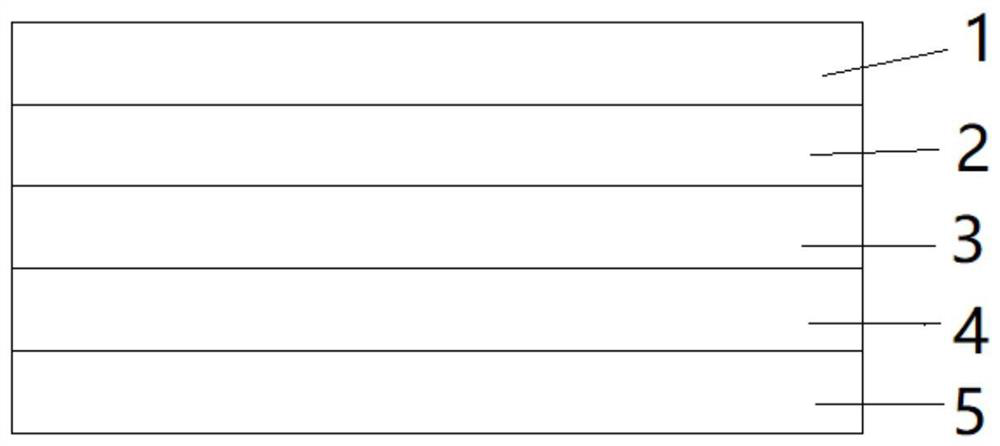

[0092] Combine below figure 1 To illustrate this embodiment, a composite anti-fouling, anti-ultraviolet, heat-insulating and heat-insulating polyester film includes a finishing layer 1, a metal coating layer 2, a heat-insulating layer and a core layer 4. The thermal insulation layer can block more than 99% of ultraviolet rays and more than 85% of infrared rays, and has excellent thermal insulation performance. The heat insulation layer includes an upper heat insulation layer 3 and a lower heat insulation layer 4, and the total thickness of the upper heat insulation layer 3 and the lower heat insulation layer 4 is 8 μm. The decoration layer 1, the metal coating layer 2, the upper heat insulation layer 3, the core layer 4 and the lower heat insulation layer 5 are arranged in sequence from top to bottom. The overall thickness of the polyester film was 30 μm.

[0093] When preparing the composite anti-fouling, anti-ultraviolet and heat-insulation polyester film of the present in...

Embodiment 2

[0102] A composite anti-fouling, anti-ultraviolet, heat-insulating and heat-insulating polyester film is similar to Example 1, except that the heat-insulation layer is made of the following raw materials in weight ratio: optical-grade PET raw material particles: ultraviolet blocking masterbatch: Infrared blocking masterbatch = 97%: 1.2%: 1.8%.

Embodiment 3

[0104] A composite anti-fouling, anti-ultraviolet, heat-insulating and heat-insulating polyester film, similar to Example 1, the difference is that the metal layer is nano-scale metal copper, the modification layer is perfluorooctyltrimethoxysilane, and the heat-insulation layer The barrier masterbatch is made of optical grade PET raw material particles: UV barrier masterbatch: infrared barrier masterbatch = 97%: 1.5%: 1.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com