Fuel cell coolant temperature control method, system and controller thereof

A cooling liquid temperature, fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of slow fan startup response speed, control deviation, slow response speed, etc., to shorten the closed-loop control time , The effect of reducing fan loss and reducing control deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

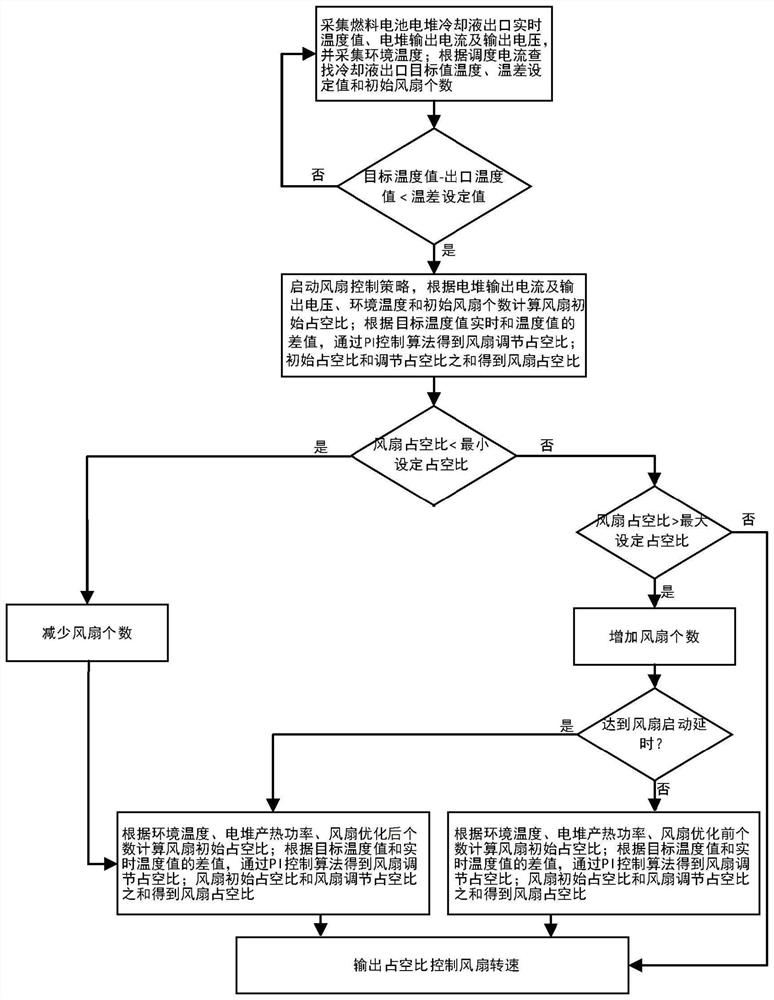

[0033] This embodiment provides a method for controlling the temperature of the fuel cell coolant, setting the corresponding temperature difference setting value according to different dispatching currents, and starting the fan control strategy; ) Calculate the initial duty cycle of the fan. On the basis of the initial duty cycle of the fan, the closed-loop control is used to obtain the duty cycle of the fan, which shortens the closed-loop control time and reduces the control deviation; Work within the maximum efficiency range to reduce fan loss and avoid noise caused by large fan duty ratios; during fan switching, consider the fan startup delay, and calculate the duty cycle according to the original number of fans before reaching the fan delay. After the fan is delayed, the duty cycle is calculated according to the number of new fans to prevent the temperature overshoot caused by the fan startup delay.

[0034] like figure 1 As shown, the fuel cell cooling liquid temperature...

Embodiment 2

[0044] This embodiment provides a fuel cell coolant temperature controller, including:

[0045] The acquisition module is used to collect the real-time temperature value of the fuel cell stack coolant outlet, the output current and output voltage of the stack, and collect the ambient temperature; find the target value temperature of the coolant outlet, the temperature difference setting value and the initial number of fans according to the scheduling current ;

[0046] The judging module is used to judge whether the difference between the target temperature value of the coolant outlet and the real-time temperature value of the coolant outlet is less than the set value of the temperature difference, if it is greater than or equal to the set value of the temperature difference, then transfer to the acquisition module; Then start the fan control strategy and go to the computing module;

[0047] The calculation module is used to calculate the heat production power of the stack ac...

Embodiment 3

[0052] This embodiment is based on the controller provided in Embodiment 2:

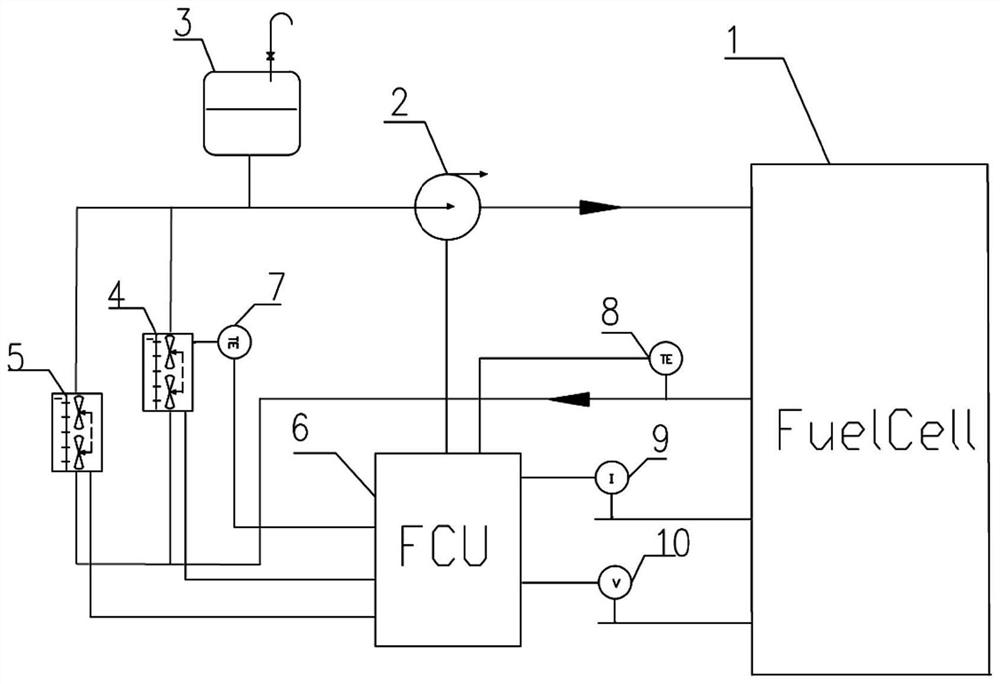

[0053] This embodiment provides a fuel cell coolant temperature control system, such as figure 2 As shown, it includes a fuel cell 1, a water pump 2, a supplementary water tank 3, m radiators 4, m·n fans 5, a controller 6, an ambient temperature sensor 7, a coolant temperature sensor 8, a current sensor 9 and a voltage sensor 10 , where m, n≥2, the fuel cell 1 is connected to the radiator 4 through pipelines, and the radiators 4 dissipate heat in parallel. Each radiator 4 has n groups of fans 5 on it, and the radiator 4 is connected to the water pump 2 through pipelines , the outlet of the water pump 2 is connected with the inlet of the fuel cell 1 to form a whole cooling circuit; the ambient temperature sensor 7 is installed near the air inlet of the fan 5, the coolant temperature sensor 8 is installed at the coolant outlet of the fuel cell 1, and the current sensor 9 and the voltage sensor 10 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com