Radio frequency socket automatic assembling equipment

An automatic assembly and radio frequency technology, which is applied in the assembly/disassembly of contacts, the manufacture of contact boxes/bases, circuit/collector parts, etc. Assembly and other problems, to achieve high work efficiency, improve product quality, save labor costs and labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The application will be described in further detail below in conjunction with the accompanying drawings.

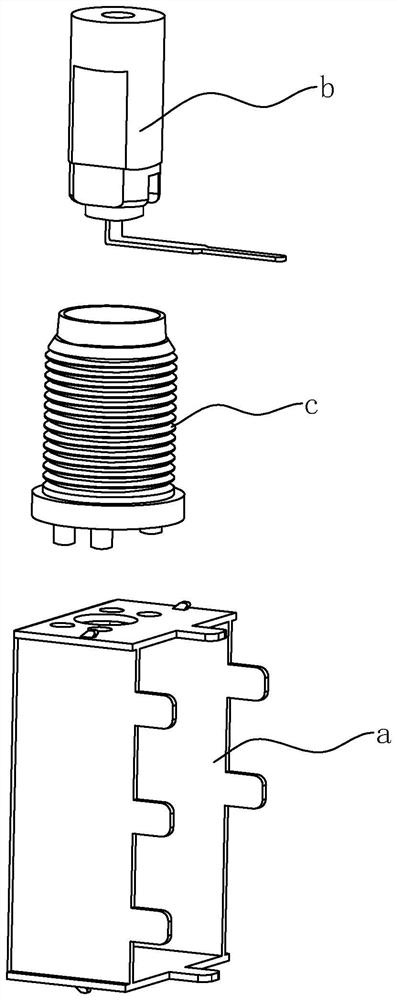

[0043] The embodiment of the present application discloses an automatic assembly equipment for a radio frequency socket.

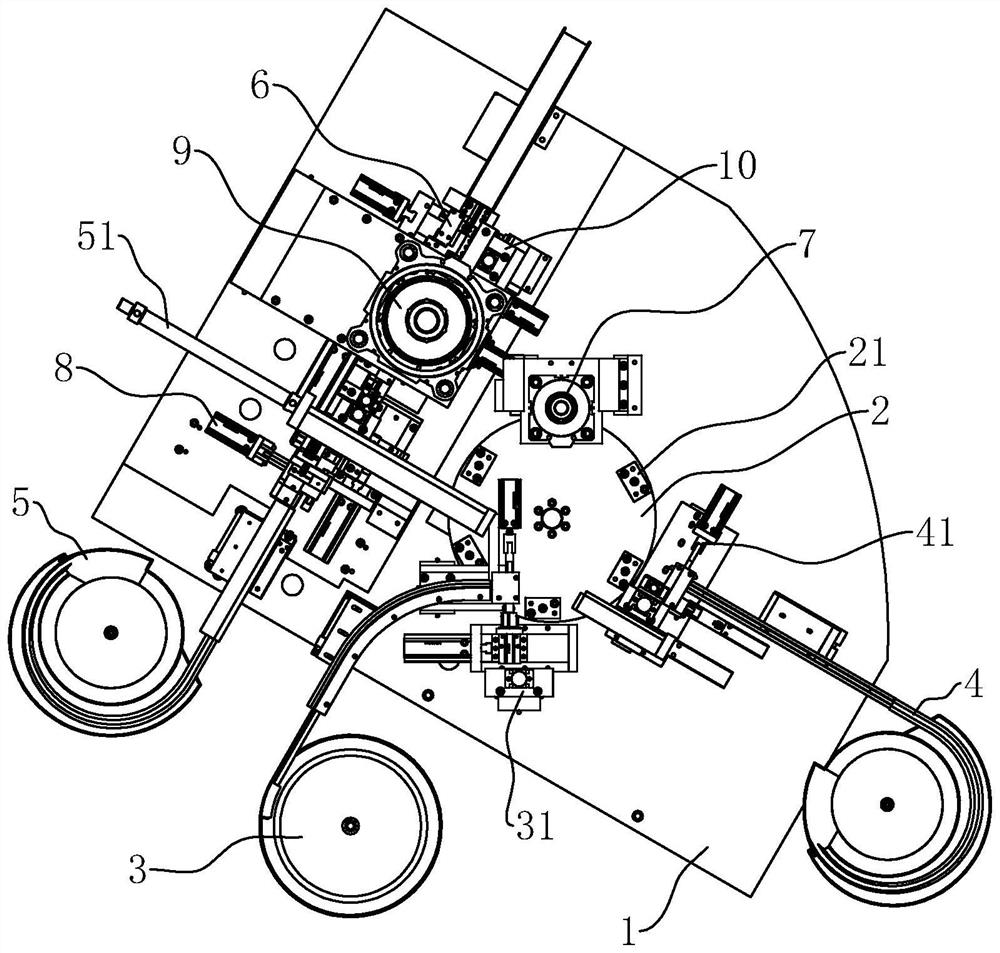

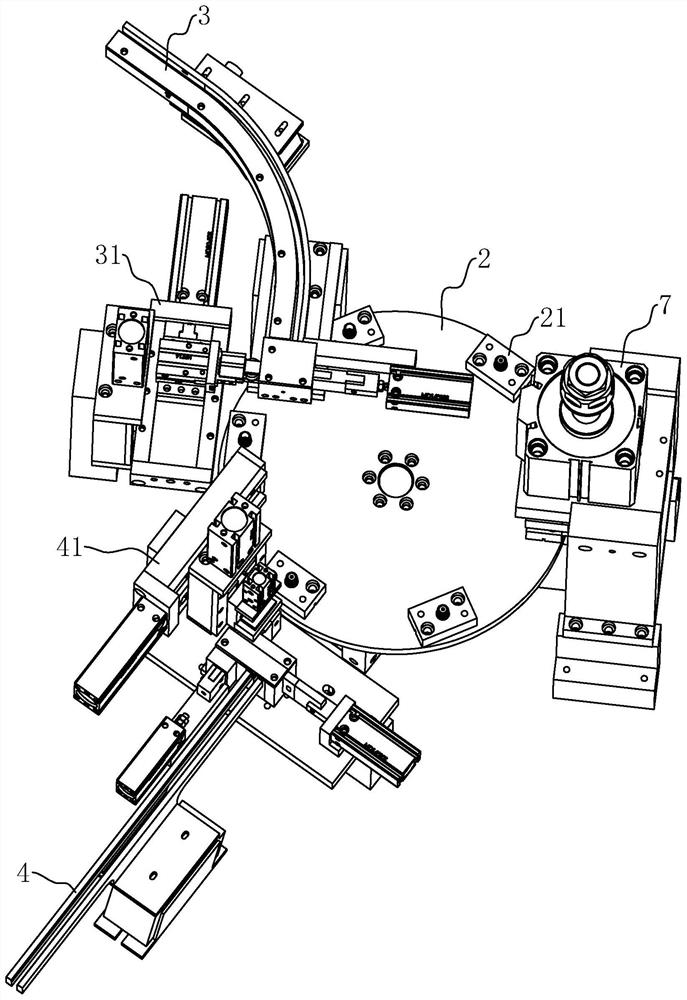

[0044] refer to figure 2 , image 3 The radio frequency socket automatic assembly equipment includes a frame 1, a working turntable 2 arranged on the frame 1 for intermittent rotation, a plurality of tooling fixtures 21 arranged in a circular shape on the working turntable 2, and sequentially arranged on the frame 1 for A threaded cylinder conveying mechanism 3 for automatically arranging and conveying threaded cylinders, a pin conveying mechanism 4 for automatically arranging and conveying pin terminal assemblies, a seat conveying mechanism 5 for automatically arranging and conveying seat bodies; The threaded cylinder transfer mechanism 31 is used to transfer the threaded cylinder at the discharge end of the threaded cylinder conveying mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com