Automatic stepless variable power speed regulation motor and speed regulation method thereof

A speed-regulating motor, stepless technology, applied in the direction of a single motor speed/torque control, electromechanical devices, electrical components, etc., can solve the problems of unsatisfactory speed regulation effect and difficulty in magnetic regulation of permanent magnet synchronous motor. The effect of moving difficulty and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

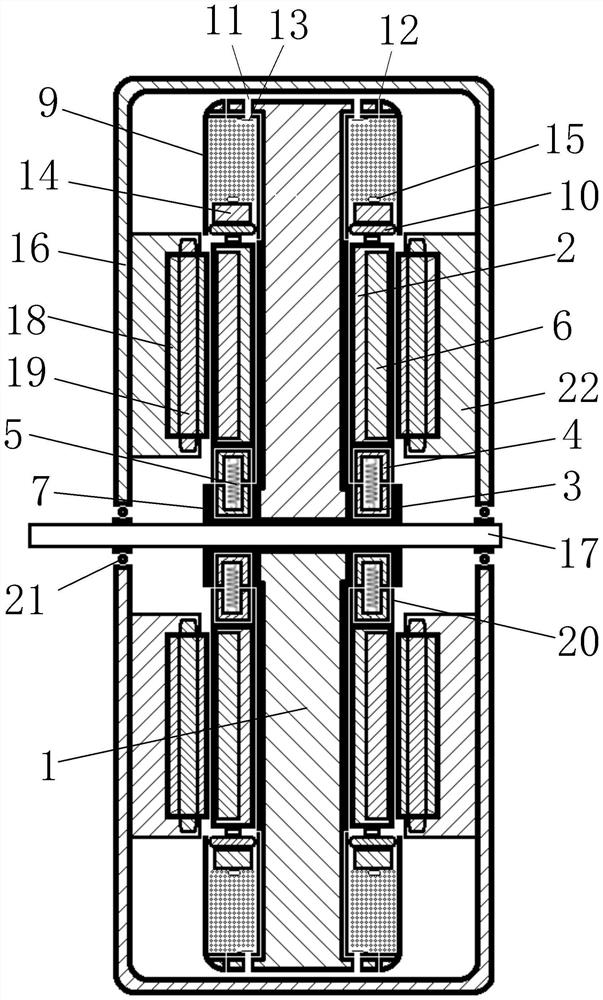

[0044] Such as figure 1 The shown automatic stepless power variable speed regulating motor includes a casing 16, a stator assembly and a rotor assembly located in the casing 16, and a main shaft 17 connected to the rotor assembly; the stator assembly includes a stator core 18 . The stator coil 19, the rotor assembly includes a rotor 1, a rotor core 2, and a rotor magnet 6;

[0045] The stator assembly and the rotor assembly are axially distributed along the main shaft 17;

[0046] The rotor core 2 is slidably fitted on the end face of the rotor 1 facing the direction of the stator assembly along the radial direction;

[0047] It also includes a radial clutch device arranged at the inner diameter end of the rotor core 2, and an air damping centrifugal device arranged at the outer diameter end of the rotor iron core 2; the radial clutch device is used to control the separation and engagement of the rotor iron core 2 in the radial direction, The air damping centrifugal device i...

Embodiment 2

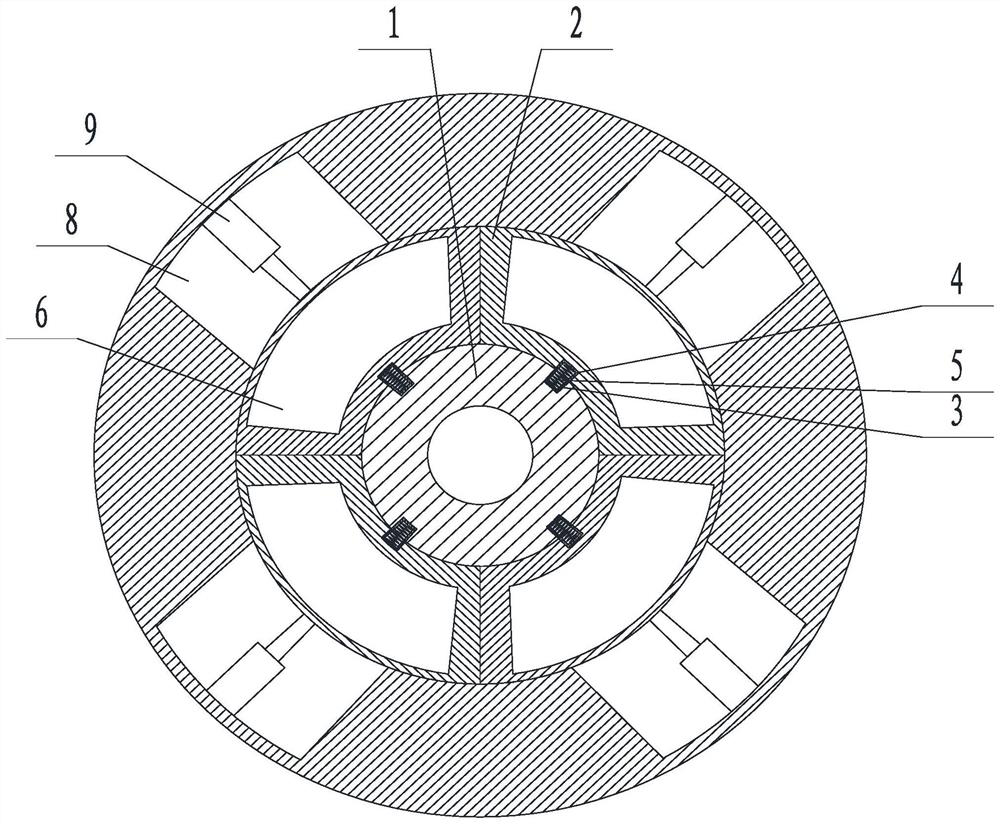

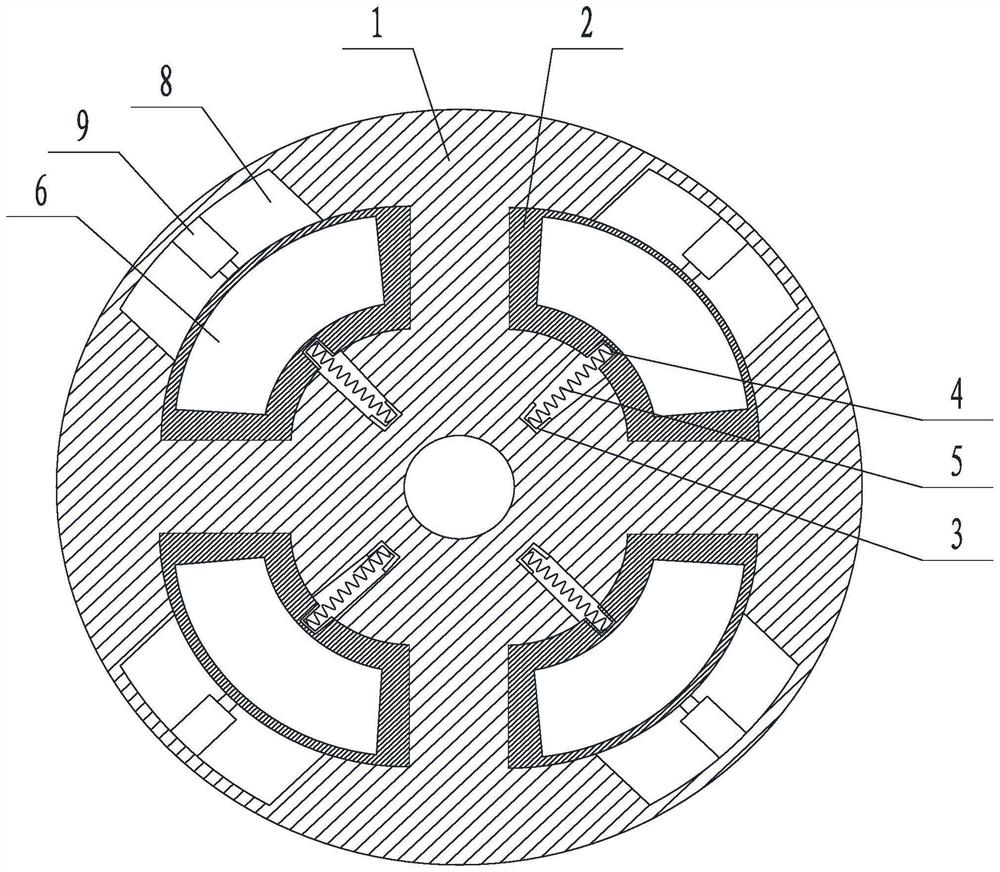

[0057] An automatic stepless power variable speed regulating motor. On the basis of Embodiment 1, the radial clutch device includes a first magnetic part 3 and a second magnetic part 4 distributed along the sliding direction of the rotor core 2. The first magnetic part A magnetic part 3 is relatively fixed to the rotor 1, the second magnetic part 4 is relatively fixed to the rotor core 2, and the first magnetic part 3 and the second magnetic part 4 are magnetically attracted; 3 and the elastic part 5 between the second magnetic part 4. Wherein the first magnetic part 3 is located on the radially inward side of the second magnetic part 4 .

[0058] This embodiment is in stationary state or low-speed rotation as figure 2 Shown; when the rotor rotates at high speed, such as image 3 As shown, the rotor core moves radially outward under the action of centrifugal force, which weakens the magnetic field strength between the rotor magnet and the stator core, and realizes the funct...

Embodiment 3

[0066] An automatic stepless power variable speed regulating motor. On the basis of any of the above embodiments, the air damping centrifugal device includes a rotor 1, a rotor core 2 matching the rotor 1, and the rotor core 2 Slidingly fit on the end surface of the rotor 1 in the radial direction; it also includes a damping cylinder 9 arranged on the end surface of the rotor 1 and located radially outside the rotor core 2, and a piston 10 located in the damping cylinder 9, the piston 10 and the rotor iron The core 2 is fixedly connected, and an air inlet 11 and an air outlet 12 are provided on the damping cylinder 9 . A one-way valve 13 is provided at the air inlet 11 , and the one-way valve 13 leads toward the direction of entering the inside of the damping cylinder 9 .

[0067] Such as figure 1 As shown, this embodiment also includes a counterweight 14 fixedly connected with the piston 10 . The counterweight 14 is fixed on the radially outer side of the piston 10 . It al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com