Full-automatic production encrusting machine for food engineering

A food engineering and fully automatic technology, applied in the fields of application, food science, dough processing, etc., can solve the problems of inconvenient cleaning for the stuffing machine, difficult to clean the spiral part, inconvenient replacement and maintenance, etc., so as to reduce the difficulty , to avoid impact, to ensure the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

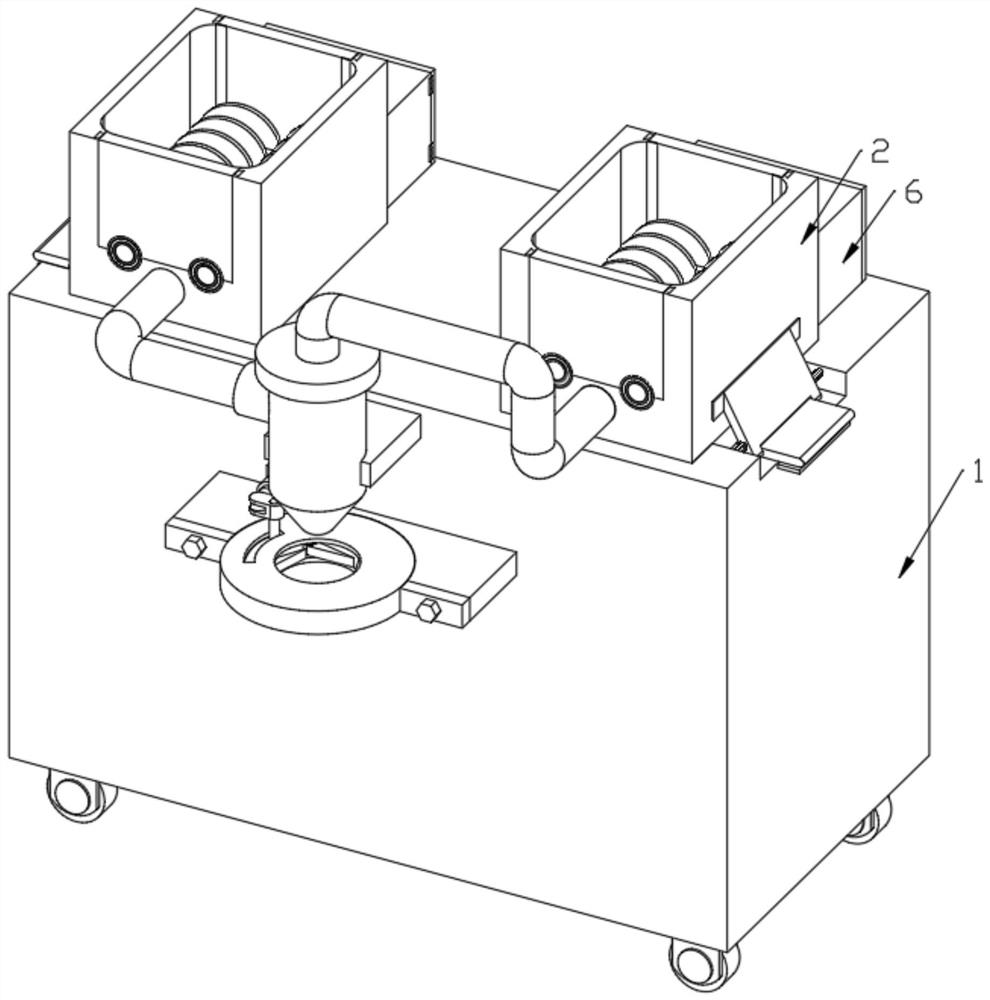

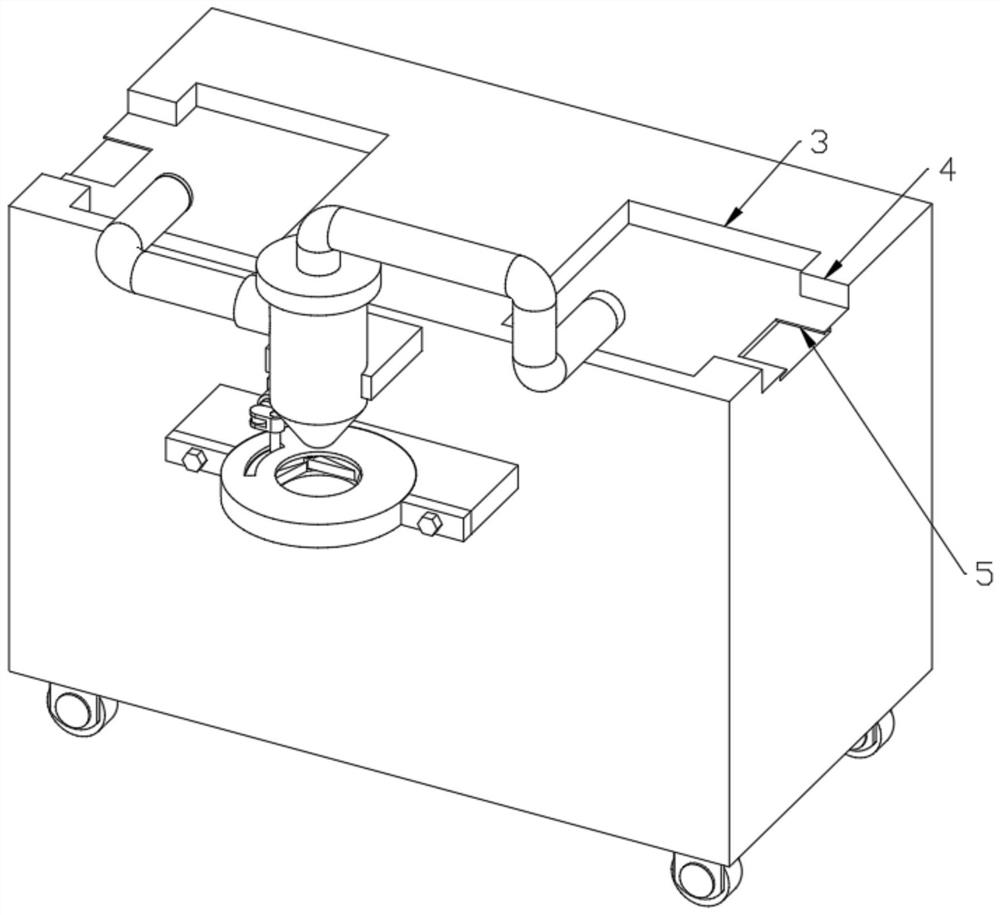

[0035] refer to Figure 1-5, a fully automatic stuffing machine for food engineering, including a processing table 1, a clamping mechanism 7 and a protective mechanism 6, universal wheels are arranged around the lower surface of the processing table 1, and a fixed The front surface of the fixed plate is connected with a discharge device for dough and filling materials, the front surface of the processing table 1 is provided with a cutting device for wrapping the filling dough, and the left and right sides of the upper surface of the processing table 1 are provided with placement slots 3 , the outer edges of the two placement slots 3 are provided with a chute-5;

[0036] Both chute 1 and 5 are provided with a fastening mechanism 7 for fixing the dough mechanism 4 and the stuffing mechanism 2;

[0037] The dough mechanism 4 is placed in the placement groove 3 on the left side of the upper surface of the processing table 1, and the filling material mechanism 2 is placed in the p...

Embodiment 2

[0045] Embodiment 2: the difference based on Embodiment 1 is;

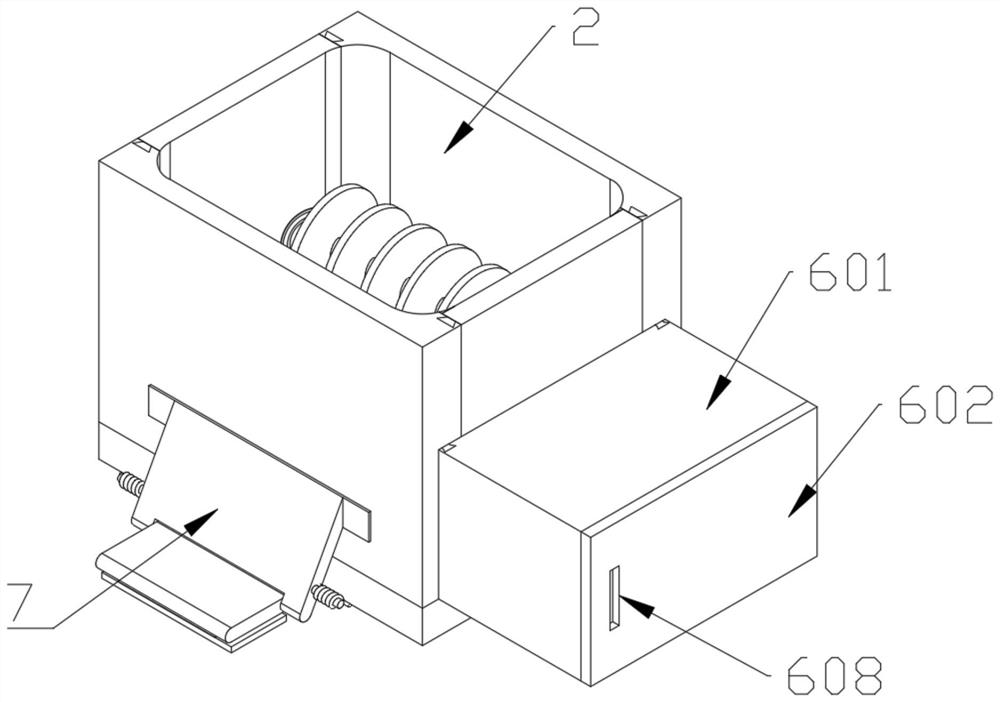

[0046] refer to Figure 6-7 , the pulling mechanism 206 includes clamping plates 2061, two clamping plates 2061 left and right sides are provided with moving plates 1 2062, four moving plates 1 2062 are movably arranged in four moving slots 1 204 respectively, and the two clamping plates 2061 The lower surface is provided with two upper card slots 2063, and each upper card slot 2063 and each lower card slot 205 are provided with block slots on the left and right sides. Through the pulling mechanism 206, it is convenient for the user to pull the auger blade 2022 Take it off from the pull mechanism 206 for cleaning.

[0047] When flushing the inside of the storage box 201, in order to ensure that the flushing is clean, the auger blade 2022 needs to be removed for cleaning, and the clamping plate 2061 is pulled upwards, and the moving plates one 2062 on both sides of the clamping plate 2061 are in the moving groove ...

Embodiment 3

[0048] Embodiment 3: the difference based on embodiment 1 is;

[0049] refer to Figure 8-9 , the positioning mechanism 607 includes a circular pin 1, and the outer surface of the cylindrical pin 6072 is rotated to be provided with a positioning plate 6071, and the upper and lower sides of the outer surface of the cylindrical pin 6072 are provided with a torsion spring 1 6073, and the upper and lower ends of the cylindrical pin 6072 are connected with each other. The upper and lower surfaces of the protective box 601 are connected. The ends of the two torsion springs 6073 close to the positioning plate 6071 are fixedly connected to the positioning plate 6071. The ends of the two torsion springs 6073 away from the positioning plate 6071 are connected to the upper and lower surfaces of the protective box 601. Fixedly connected, one end of the positioning plate 6071 close to the inner chute 603 of the protective box 601 is set in the positioning groove 2027 on the placing platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com